Blog

2025 Guide: How to Choose the Right Hydraulic Rotary Actuator for Your Needs

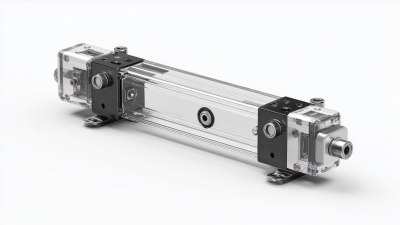

In the world of industrial automation and machinery, choosing the right hydraulic rotary actuator is pivotal for ensuring operational efficiency and reliability. These devices play a crucial role in converting hydraulic pressure into rotational motion, making them essential components in various applications, from automotive to aerospace. As industries continue to evolve, the demand for specialized hydraulic rotary actuators that can meet specific needs becomes increasingly important.

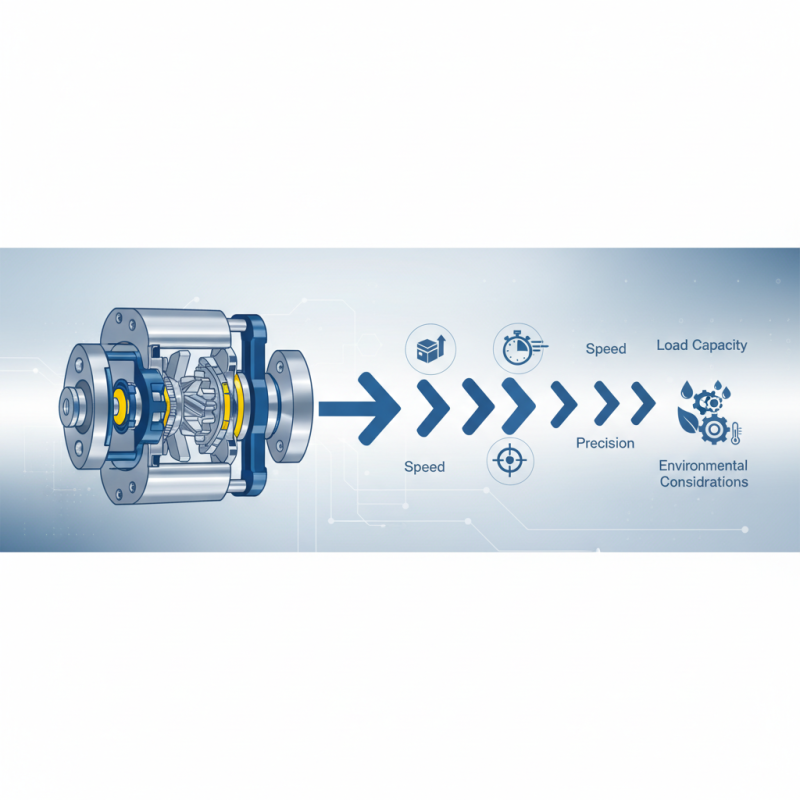

This comprehensive guide for 2025 aims to equip readers with the knowledge needed to select the most suitable hydraulic rotary actuator for their applications. It highlights key factors such as load capacity, speed, precision, and environmental considerations. Understanding these parameters is vital for optimizing performance and achieving desired outcomes in both existing systems and new projects.

With advancements in technology and an array of options available in the market, the decision-making process can be overwhelming. This article will simplify the selection process, enabling you to make informed choices that align with your operational requirements and enhance overall productivity. Whether you are a seasoned engineer or just starting in your field, this guide will provide valuable insights to help you navigate the complexities of hydraulic rotary actuators.

Understanding Hydraulic Rotary Actuators: Types and Applications

Hydraulic rotary actuators are critical components in various industrial applications, providing precise control of motion in rotating tasks. These actuators leverage hydraulic pressure to generate torque, enabling them to perform significant work across a spectrum of fields, including manufacturing, robotics, and aerospace. According to a report by Grand View Research, the global market for hydraulic actuators is expected to reach $5.8 billion by 2025, reflecting a growing demand for automation and system efficiencies. Understanding the different types of hydraulic rotary actuators available is essential for selecting the right model for your specific needs.

There are primarily two types of hydraulic rotary actuators: single-acting and double-acting. Single-acting actuators use hydraulic fluid to create motion in one direction and rely on external force, such as a spring return, for the return stroke. In contrast, double-acting actuators utilize hydraulic pressure for both the rotation and return motion, offering more control and efficiency for applications requiring complex movements. Applications range from simple valve operations to complex robotic assemblies, where accuracy and reliability are paramount. Industry data indicates that sectors like oil and gas, where equipment maintenance is crucial, increasingly rely on these actuators to enhance performance and reduce downtime, showcasing their versatility in demanding environments.

Key Factors to Consider When Choosing a Hydraulic Rotary Actuator

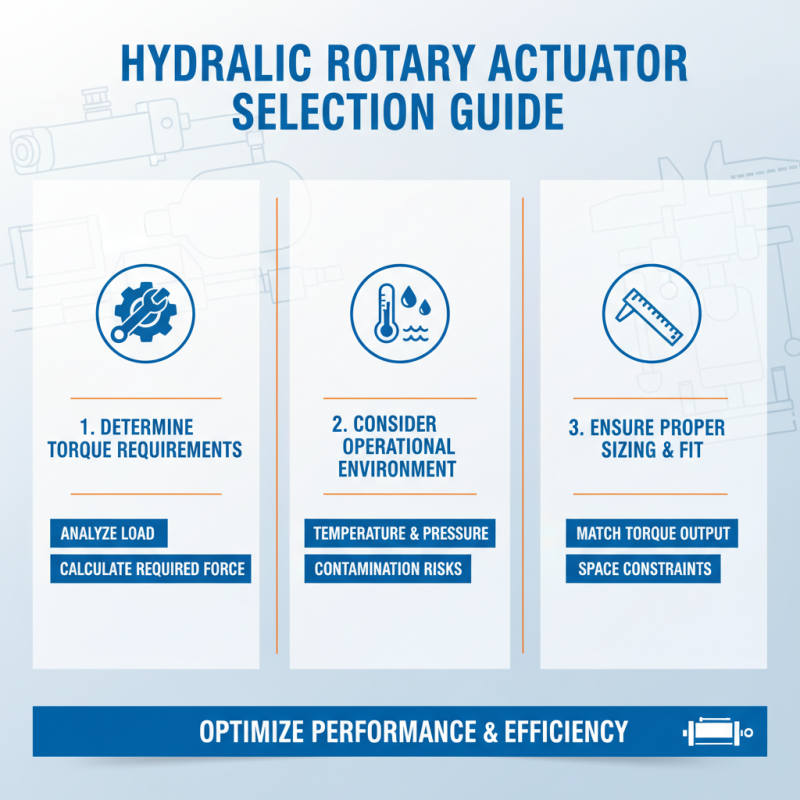

When selecting a hydraulic rotary actuator, several key factors must be taken into account to ensure that the device meets your specific application requirements. First and foremost, consider the torque output needed for your operation. Torque requirements will vary depending on the load being moved or controlled, as well as the dynamics of the application. A thorough analysis of the operational parameters, including any potential load variations, is essential to choose an actuator that delivers reliable performance.

Another crucial factor is the actuator's speed capabilities. Different applications will demand different speed requirements for effective operation. Evaluating the desired rotation speed, along with the response time necessary for your system, will guide you towards an actuator that not only matches these criteria but also operates efficiently within its designed limits. Additionally, understanding the operating environment, including temperature ranges and exposure to contaminants, will influence the materials and design choices, ensuring long-term durability and functionality in your application.

2025 Guide: How to Choose the Right Hydraulic Rotary Actuator for Your Needs

| Parameter | Description | Recommended Value |

|---|---|---|

| Torque Output | The maximum torque the actuator can provide. | 50 - 2000 Nm |

| Rotational Speed | Speed at which the actuator can rotate. | 0.5 - 10 RPM |

| Operating Pressure | Pressure range within which the actuator operates efficiently. | 50 - 300 Bar |

| Duty Cycle | The time the actuator can operate continuously. | 50% - 100% |

| Mounting Type | The configuration in which the actuator is mounted. | Flange, Foot, or Cart |

| Temperature Range | Operating temperature limits. | -20°C to 80°C |

| Materials | Materials used in the actuator construction. | Aluminum, Steel, or Composite |

| Control Type | Method of controlling the actuator. | Manual, Electric, or Hydraulic |

Sizing and Torque Requirements for Your Specific Application

When selecting a hydraulic rotary actuator, understanding the sizing and torque requirements for your specific application is crucial. The actuator's size should be determined based on the torque output needed to perform the intended tasks efficiently. Analyzing the load and the operational environment will help you pinpoint the required specifications. Remember that the actuator must not only fit into the designated space but also provide adequate force to manage the system's demands.

Tips: Always calculate the peak torque and consider safety factors to accommodate unexpected loads. A well-rounded approach includes evaluating the actuator's speed and responsiveness, as these factors will significantly influence overall performance.

Additionally, consider the mounting options and connectivity of the actuator. Compatibility with existing systems and ease of installation should not be overlooked. If the actuator needs to operate in harsh conditions, select a model with protective features. This way, you ensure longevity and reliability in your operations, leading to improved productivity in the long run.

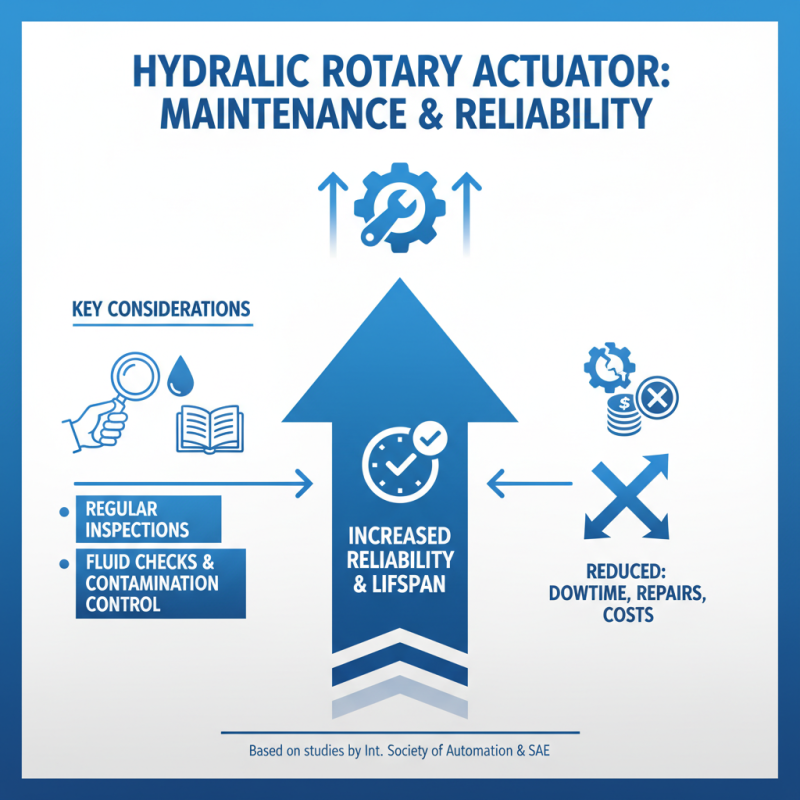

Maintenance and Reliability Considerations for Hydraulic Rotary Actuators

When selecting a hydraulic rotary actuator, maintenance and reliability are paramount considerations. According to a study conducted by the International Society of Automation, improper maintenance can significantly reduce the lifespan of hydraulic actuators, often leading to unexpected downtime and costly repairs. Regular inspections and adherence to manufacturer maintenance schedules can enhance the reliability of these actuators. For instance, the Society of Automotive Engineers reports that consistent fluid checks and contamination control can improve operational efficiency by up to 30%.

Tips: Schedule periodic lubrication and replace seals and gaskets as recommended to minimize leaks and potential failures. Incorporate predictive maintenance techniques using data analytics to foresee issues before they arise, ensuring your actuator runs smoothly and effectively.

In addition, understanding the operating environment is crucial. Hydraulic rotary actuators exposed to extreme temperatures or hazardous conditions may require specialized materials or designs to withstand the stress. A report from the Hydraulic Institute suggests that actuators designed with corrosion-resistant components can extend service life by approximately 40%. Consulting with experts in actuator technology can provide insights tailored to specific industrial needs, ensuring that reliability does not take a backseat to performance.

Tips: Always assess the installation location for potential environmental challenges and choose actuators specifically engineered to combat these situations. Regularly updating your knowledge on industry best practices can also play a crucial role in maintaining the efficacy of your hydraulic systems.

Cost-Benefit Analysis: Budgeting for Your Hydraulic Actuator Choice

When considering the costs associated with hydraulic rotary actuators, it's crucial to conduct a comprehensive cost-benefit analysis to align your selection with your project budget and operational needs. Start by assessing the initial purchase price of the actuator alongside its installation and integration costs. While cheaper models may seem appealing at first, it's essential to evaluate their long-term reliability and maintenance requirements, as higher maintenance costs can erode any initial savings. Look for models with a proven track record of durability to ensure that your investment will pay off over time.

In addition to upfront expenses, consider the operational efficiency and energy consumption of different hydraulic rotary actuators. More efficient actuators may come with a higher price tag, but they often lead to significant savings in energy costs and reduced downtime. Factor in the expected lifespan of the actuator and the potential productivity gains from faster, more reliable performance. By weighing these aspects carefully, you can make an informed decision that balances your budget with the long-term benefits, ensuring that you select a hydraulic rotary actuator that meets both your financial constraints and performance expectations.

Related Posts

-

Unlocking Precision: How Hydraulic Rotary Actuators Revolutionize Industrial Automation

-

Top 10 Hydraulic Actuators: Boost Your Machinery Efficiency Today

-

Top 10 Globe Valves Types and Their Applications in Industrial Systems You Should Know

-

Exploring Duplex Strainer Innovations at the 138th Canton Fair in 2025

-

Top 5 Types of Butterfly Valves You Need to Know for Optimal Performance

-

Unlocking Automation: The Future of Electric Actuators in Smart Technology