Blog

2026 Top Check Valves Types and Their Applications Guide?

Check valves play a crucial role in fluid systems. They allow flow in one direction and block reverse flow. These valves are vital in various industries, from oil and gas to pharmaceuticals. According to a recent industry report, the global check valve market is projected to reach $8 billion by 2026. This growth indicates rising demand across several sectors.

Different types of check valves exist, each designed for specific applications. For example, spring-loaded check valves offer quick response times. Meanwhile, tilting disc check valves excel in high-flow environments. However, the choice of valve can often be overlooked. Many engineers face challenges in selecting the appropriate valve type.

Understanding the unique features of each check valve is critical. Some applications may require regular maintenance or specific materials. Despite being a common component, the decision-making process can be complex. It's essential to stay informed about the latest advancements and best practices in check valve selection.

Types of Check Valves: An Overview of Common Designs and Mechanisms

Check valves are essential components in fluid systems. They ensure that fluid flows in one direction only, preventing backflow. Several designs exist, each with unique mechanisms suited for specific applications. The two most common types are swing check valves and lift check valves.

Swing check valves operate with a hinged disc. This design allows for minimal pressure drop, making it ideal for water and steam systems. According to industry reports, swing check valves hold approximately 65% of the market share in water applications. On the other hand, lift check valves use a disk that moves vertically. This design is beneficial in high-pressure scenarios, such as gas pipelines, where reliability is crucial.

Another noteworthy type is the diaphragm check valve. This design is less common but has specific advantages. It is great for applications requiring tight sealing and minimal leakage. However, it can be more sensitive to debris in the fluid. A study highlighted that more than 30% of system failures in certain industries were linked to check valve malfunctions. Considering these factors helps engineers select the right valve for their needs.

2026 Top Check Valves Types and Their Applications Guide

| Type of Check Valve | Mechanism | Applications | Advantages |

|---|---|---|---|

| Swing Check Valve | A disc swings on a hinge to allow flow in one direction. | Water supply, sewage, and pump discharge systems. | Simple design, low-pressure drop, suitable for large diameter piping. |

| Lift Check Valve | A disc moves up and down, blocking flow when reversed. | Oil and gas applications, water treatment facilities. | Compact design, can handle high pressure and flow rates. |

| Dual Plate Check Valve | Two plates pivot to open and close flow. | Power plants, chemical processing, and HVAC systems. | Reduced weight, low-pressure drop, quick response to flow changes. |

| Stop Check Valve | Combines a check function with a manual stop feature. | Pump systems, waste treatment plants, and boiler feedwater systems. | Allows manual control of flow, prevents backflow. |

| Spirit Check Valve | Utilizes a ball or disc that sits within a seat to block flow. | Chemical processing, pharmaceutical, and food industries. | Simple structure, reliable sealing, and ease of maintenance. |

Applications of Check Valves in Various Industries: Insights and Trends

Check valves play a crucial role in various industries. They prevent backflow and protect equipment. Their design varies based on the application. In water management systems, check valves ensure a smooth flow. They maintain pressure and reduce water hammer. However, maintenance is necessary to avoid blockages.

In the oil and gas sector, check valves are essential for safety. They prevent reverse flow in pipelines. A failure can lead to serious consequences. Regular inspections are vital to ensure reliability. In these industries, small issues can escalate quickly. Operators should remain vigilant.

Manufacturing facilities also benefit from check valves. They manage fluid levels in different processes. These valves help in maintaining efficiency. Yet, the environment can affect performance. Factors like corrosion and temperature should be monitored. A proactive approach is essential for long-term success.

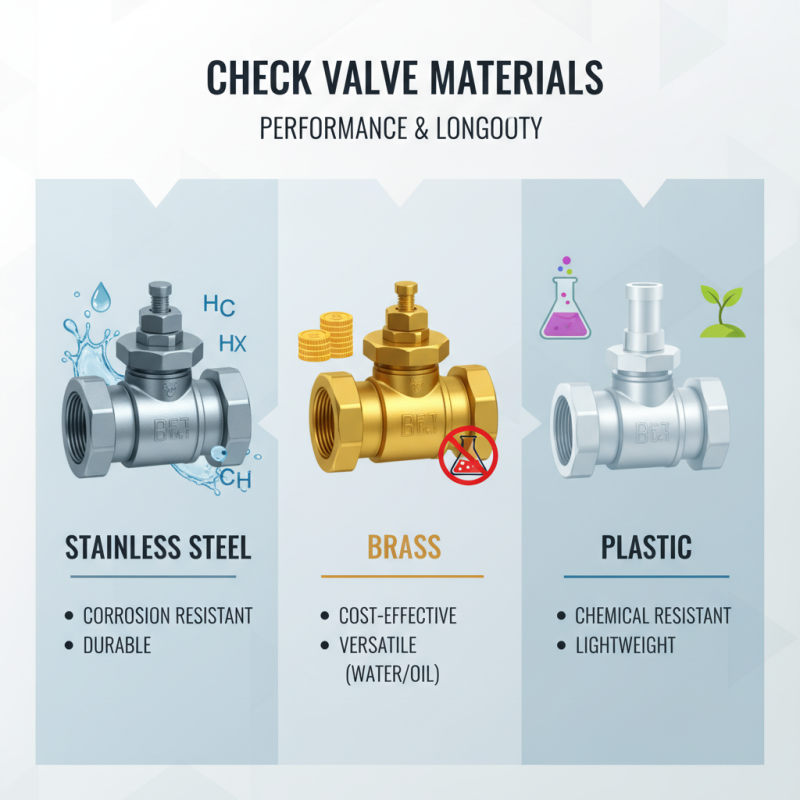

Material Selection for Check Valves: Impact on Performance and Longevity

Material selection for check valves is crucial for both performance and longevity. The most common materials include stainless steel, brass, and plastic. Each has distinct advantages and disadvantages. For example, stainless steel offers excellent corrosion resistance but can be expensive. Brass is often more affordable, yet it may not withstand harsh chemicals.

Consideration of the fluid type is essential. Some materials degrade quicker than others when exposed to certain chemicals. Plastic check valves can handle corrosive fluids but may lack the durability needed in high-pressure applications. A poor choice in material could lead to leaks or valve failure.

Maintenance plays a significant role in the overall longevity of check valves. Regular inspections can reveal wear and tear. Inadequate maintenance might result in costly downtime. Understanding the material's limitations and the specific application can make all the difference in a valve's lifespan. Choices matter.

Key Performance Metrics for Check Valves: Pressure, Temperature, and Flow Rates

Check valves play a critical role in fluid systems. Key performance metrics include pressure, temperature, and flow rates. Understanding these metrics helps in selecting the right check valve type for specific applications.

Pressure ratings are essential. Many check valves operate in systems with pressures ranging from 100 psi to 1,500 psi. Some high-performance valves can manage even greater pressures. This varies widely based on the material and design.

Temperature is another crucial factor. Check valves can function in environments from -20°F to 400°F. However, extreme temperatures may degrade materials over time. Flow rates, typically expressed in gallons per minute (GPM), impact system efficiency. For instance, a valve designed for a 150 GPM flow rate may not work as effectively at 300 GPM.

Improperly selected valves can lead to significant issues. Leaks and failure are common pitfalls. It's vital to analyze these metrics when choosing a valve. Engineers must take the time to verify compatibility and expected performance.

Future Trends in Check Valve Technology: Innovations and Market Projections

The future of check valve technology is promising. Innovations are emerging across various industries. Companies are focusing on efficiency and durability. Smart check valves are gaining traction. They integrate sensors and IoT technology. This evolution improves system monitoring and performance. Real-time data helps in making informed decisions.

Market projections indicate a growing demand. Key sectors include water management and oil and gas. These industries require reliable and efficient solutions. The push for sustainability is another factor. New materials and designs minimize environmental impact. However, challenges remain. Manufacturers need to balance cost and reliability.

As technology advances, competition will increase. Some solutions may not meet expectations. Continuous improvement is crucial. There is a need for more rigorous testing and validation. Stakeholders should remain aware of these dynamic trends. Adaptability will determine future successes in the check valve market.

2026 Top Check Valve Types and Their Applications

Related Posts

-

10 Essential Tips for Choosing the Right Check Valves for Your Projects

-

Understanding the Importance of Spring Check Valve in Modern Plumbing Systems

-

Understanding Electric Actuators: Revolutionizing Automation in Modern Industries

-

Top 10 Uses of Air Actuator in Modern Technology?

-

The 7 Best Air Actuators for Enhanced Performance and Efficiency

-

Exploring the Future of Control Valves in Sustainable Industrial Applications