Blog

2026 Top Globe Valves Types for Industrial Applications?

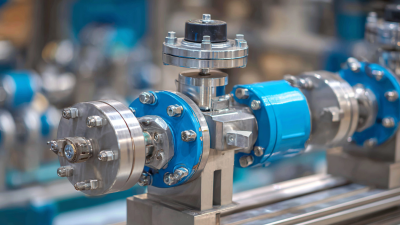

In the realm of industrial applications, understanding different types of globe valves is essential. Experts emphasize their importance for effective fluid handling. According to Dr. Jane Lee, a prominent figure in valve technology, "Globe valves provide reliable flow control in complex systems." Her insight highlights their critical role.

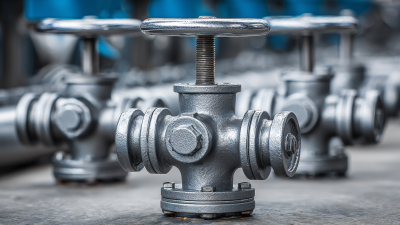

Globe valves are designed to manage fluid flow efficiently. They are particularly effective in high-pressure and high-temperature environments. Their construction allows for precision control, making them essential in various sectors. However, not all globe valves are created equal. Some designs may lead to pressure drop issues. This can affect operational efficiency.

Industries continuously seek the best globe valve options. Understanding the latest designs and materials helps in making informed decisions. Choosing the right type can enhance performance significantly. Yet, challenges remain, and reflections on material sustainability and design choices are necessary. The evolution of globe valves continues, driven by innovation and necessity.

Overview of Globe Valves in Industrial Applications

Globe valves are crucial in various industrial applications. They help regulate flow and pressure in pipelines. A recent industry report indicates that the global market for globe valves is projected to grow at a CAGR of 5.2% from 2021 to 2026. This growth is largely driven by their efficiency and reliability in controlling fluid flow.

Different types of globe valves serve specific needs. For example, the Y-pattern globe valve offers lower flow resistance. This makes it suitable for high-pressure applications. However, they may not always be the best choice due to potential leakage issues. In contrast, straight-pattern globe valves are preferred for their simplicity and effectiveness. Industry experts suggest evaluating the specific requirements of each application before making a choice.

Proper maintenance is vital for the longevity of globe valves. Neglect can lead to significant operational issues. Regular inspections can help identify wear and tear. Industry studies show that over 30% of valve failures can be traced back to inadequate maintenance practices. Such statistics remind us of the importance of proactive measures.

Key Types of Globe Valves for 2026 Industrial Use

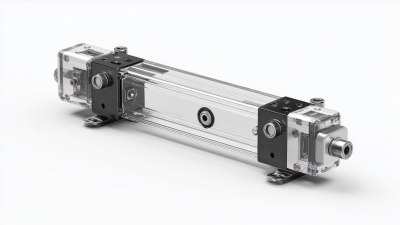

When it comes to industrial applications in 2026, globe valves stand out for their versatility. These valves effectively regulate flow and pressure in various systems. Three key types to consider are the standard globe valve, the bellow-sealed globe valve, and the angle globe valve. Each type serves a distinct purpose, influencing overall operational efficiency.

Standard globe valves are commonplace. They provide reliable performance in moderate pressure settings. However, they can be inefficient in high-pressure scenarios. Bellow-sealed globe valves excel in preventing leaks. This feature is crucial in chemical applications. Still, their higher cost might deter some users. Angle globe valves, on the other hand, facilitate better flow management. They are ideal for space-constrained setups but might complicate installation processes.

Understanding the nuances of these valve types is critical. Choosing the right type means considering factors like pressure limits and potential leakage. Sometimes, the best option can be the simplest one. An industry professional might overlook a suitable valve due to biases toward complex designs. Future selections should prioritize functionality and adaptability over brand prestige or price alone.

Comparative Analysis of Globe Valve Materials

Globe valves play a critical role in regulating flow and pressure in industrial systems. The choice of materials for these valves directly affects their performance and durability. Common materials include cast iron, stainless steel, and brass. Each has unique properties that make it suitable for specific applications.

Cast iron is often used for its strength and durability. However, it may not withstand corrosive environments well. Stainless steel, on the other hand, offers excellent resistance to corrosion and high temperatures. This makes it ideal for harsh industrial conditions. Yet, it can be expensive, which is a significant consideration for many businesses.

Brass is lightweight and has good machinability. This makes it a popular choice for smaller applications. However, it is less suitable for high-pressure environments. The choice of material ultimately depends on specific operational needs and cost considerations. It's crucial to weigh the pros and cons carefully when selecting the right globe valve for any industrial application.

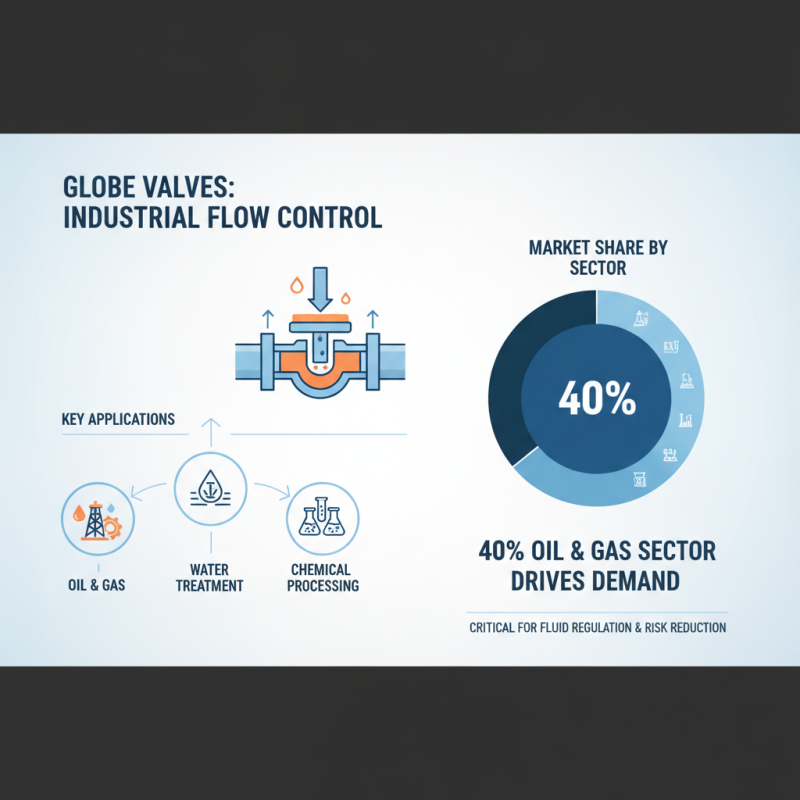

Applications of Globe Valves Across Various Industries

Globe valves play a crucial role in various industrial applications. They are widely used for controlling fluid flow in pipelines. The versatility of globe valves makes them suitable for several sectors, including oil and gas, water treatment, and chemical processing. According to a recent industry report, over 40% of the globe valve market is attributed to the oil and gas sector. This statistic underscores their importance in managing hydrocarbon flows and reducing risks.

In water treatment facilities, globe valves ensure precise flow control. They help maintain optimal pressure and prevent leaks. Furthermore, in chemical processing, the ability to handle high temperatures and pressures makes globe valves indispensable. However, not all applications run smoothly. Maintenance can prove challenging, as wear and tear are common. A study indicated that a significant number of valves fail due to improper installation and fatigue. This highlights the need for better training and awareness among operators.

Another area for concern is the environmental impact. Leakage from poorly maintained globe valves can contribute to pollution. With growing environmental regulations, industries must prioritize valve integrity. On the flip side, innovation in valve design offers solutions. Smart valves with sensors are emerging, allowing for better monitoring. This represents a promising direction for the future, but the transition requires careful consideration and investment.

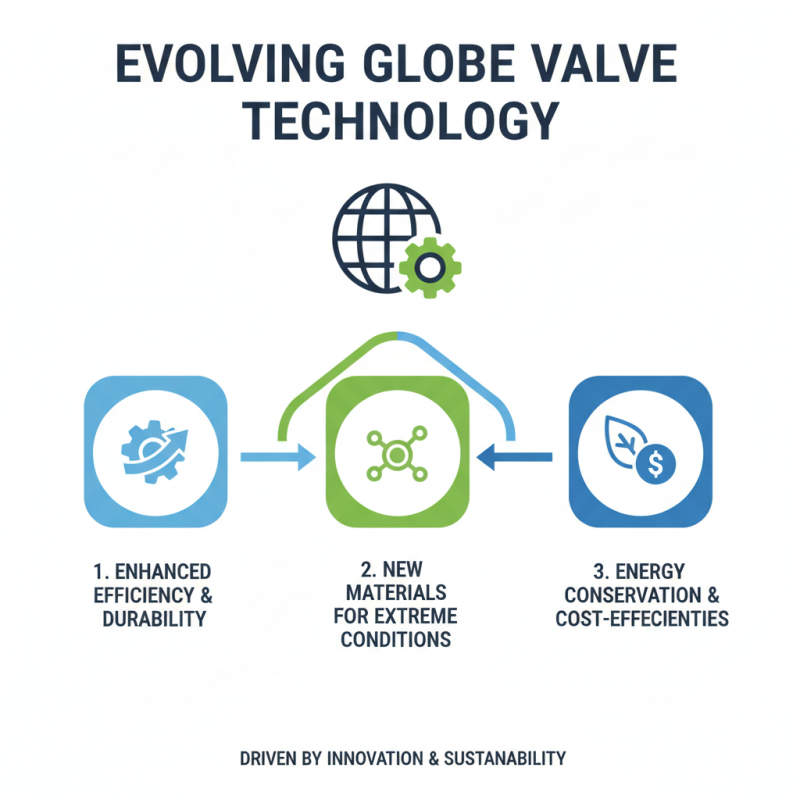

Future Trends in Globe Valve Technology and Design

The landscape of globe valve technology is evolving rapidly. Future designs will focus on enhanced efficiency and durability. New materials are being introduced to improve performance under extreme conditions. This change is driven by the need for better energy conservation and cost-effectiveness.

Tips: Regular maintenance can help extend the life of your globe valves. Check for leaks frequently. Small leaks may lead to bigger issues over time.

Smart technology is gaining traction. Sensors integrated into valves can monitor performance in real-time. This can help prevent unexpected failures. However, the dependency on technology may pose challenges in maintenance and training.

Tips: Consider investing in training for your team. Understanding these new technologies is crucial for successful implementation. Regular training sessions can keep your staff updated and reduce errors.

Improving the design process will be essential. Streamlined manufacturing techniques may lower costs. Yet, balancing cost with quality remains a challenge. There’s a risk that cheaper materials could compromise performance.

Related Posts

-

Top 10 Globe Valves Types and Their Applications in Industrial Systems You Should Know

-

How to Choose the Right Pneumatic Valve Actuator for Your Application

-

Exploring the Future of Control Valves in Sustainable Industrial Applications

-

Top 10 Reasons to Choose Stainless Steel Check Valves for Your Projects?

-

Top 5 Benefits of Using Pneumatic Butterfly Valves in Industrial Applications

-

Unlocking Automation: The Future of Electric Actuators in Smart Technology