Blog

Top Benefits of Using Air Actuators in Automation Systems?

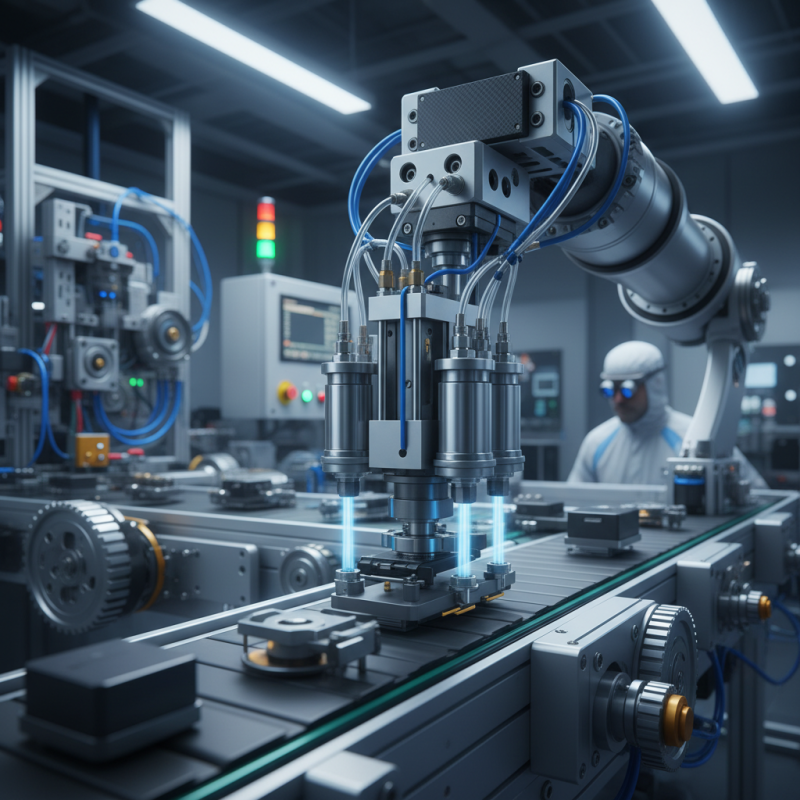

In the evolving world of automation, air actuators play a crucial role. Their efficiency and reliability set them apart from traditional systems. According to Dr. John Smith, a leading expert in automation technology, "Air actuators transform the way industries approach automation." This highlights their significance in modern processes.

Air actuators operate using compressed air, creating movement with precision. They are known for their rapid response time, making them ideal for dynamic tasks. For instance, in manufacturing, they enable quick adjustments on assembly lines. Despite their benefits, some users overlook proper maintenance. This can lead to unexpected downtime and reduced efficiency.

Implementing air actuators often requires a shift in mindset. Industries must address installation challenges and potential integration issues. Additionally, training staff to effectively use and maintain these systems is essential. While air actuators offer numerous advantages, companies should carefully consider their specific needs and applications.

Advantages of Air Actuators in Automation Systems Efficiency

Air actuators are increasingly vital in automation systems. Their ability to provide quick and precise motion gives industries a competitive edge. According to recent studies, air actuators can enhance operational efficiency by up to 30%. This efficiency stems from their lightweight nature and rapid response time.

In environments where speed is crucial, air actuators excel. They operate efficiently even in harsh conditions. With a temperature tolerance ranging from -20°C to +80°C, they maintain performance. However, they also have limitations. Air leakage is a common concern that can reduce system efficiency. Regular maintenance is required to mitigate this issue.

Data from the International Society of Automation highlights that integrating air actuators can lead to significant energy savings. Many companies report a reduction in power consumption by nearly 15%. This reduction directly translates to cost savings over time. Balancing efficiency and potential downsides is crucial for long-term success.

Cost-Effectiveness of Air Actuators Compared to Electric Actuators

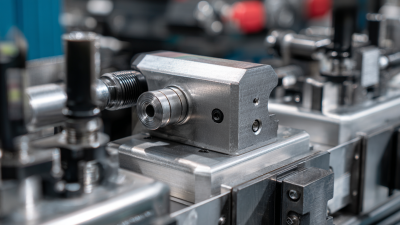

Air actuators are increasingly popular in automation systems due to their cost-effectiveness. According to a recent industry report, pneumatic systems can be 30-50% less expensive than traditional electric actuators. This cost advantage often stems from lower initial investment and reduced maintenance expenses. Companies can save significantly on system setup and long-term operation.

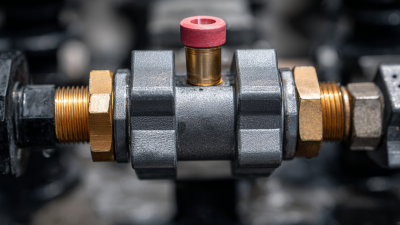

Moreover, air actuators are known for their efficiency in certain applications. They typically require less energy to operate. For example, they can provide high force output and rapid actuation without the need for extensive electrical infrastructure. Data shows that pneumatic systems offer a quicker response time in assembly line settings. However, air supply systems must be carefully managed. Leaks in pneumatic systems can lead to inefficiencies, requiring regular maintenance and occasional downtime.

Flexibility is another key factor. Air actuators can be easily integrated into existing systems. They can adapt to various tasks without major changes. However, they might not perform well in environments with specific temperature or dust conditions. This consideration is crucial when choosing between actuator types. In the end, understanding the operational demands and the overall budget is essential for making an informed choice.

Performance Metrics: Speed and Precision of Air Actuators

Air actuators play a crucial role in automation systems, offering exceptional speed and precision. They operate quickly, often achieving response times of under 50 milliseconds. This speed enhances the overall efficiency of production lines. Additionally, air actuators maintain high accuracy levels, typically within ±0.5 mm. This precision is vital in tasks requiring exact positioning.

However, there are some challenges to consider. Variability in air pressure can impact performance. If pressure fluctuates, it may affect both speed and precision. Regular maintenance can help mitigate these issues. Additionally, some applications may demand more consistent results, prompting the exploration of alternative actuator types.

Tips for optimizing performance include ensuring proper air supply. This involves checking lines for leaks and keeping components clean. Also, assessing the actuator's response time regularly can help identify potential issues before they affect productivity. Always maintain a balance between speed and precision to meet application requirements effectively.

Top Benefits of Using Air Actuators in Automation Systems

This bar chart illustrates key performance metrics for air actuators in automation systems, showcasing their speed, precision, reliability, and maintenance costs. These factors highlight the advantages of implementing air actuators in various applications.

Impact of Air Actuators on System Safety and Reliability

Air actuators offer distinct advantages in automation systems, particularly in safety and reliability. According to a recent industry report, automation systems utilizing pneumatic actuators can enhance operational safety by up to 30%. This statistic highlights their ability to operate efficiently in hazardous conditions, which reduces the risk of accidents. Operating at lower pressures than many electric systems, air actuators minimize the chances of explosions or electrical failures.

In terms of reliability, air actuators provide consistent performance, even in challenging environments. A study noted that pneumatic systems have a failure rate of only 1-2%. This reliability stems from fewer moving parts compared to their electric counterparts. However, there can be challenges. For instance, fluctuations in air pressure can affect actuator performance. Regular maintenance is essential to ensure these systems function correctly.

Moreover, the real-world impact of air actuators is significant. When properly implemented, they can boost the efficiency of various automated processes in industries like manufacturing and robotics. Though the initial setup may require careful planning, the long-term benefits often outweigh these early hurdles.

Environmental Considerations and Energy Consumption of Air Actuators

Air actuators have become popular in automation systems due to their unique benefits. One of the key aspects to consider is their environmental impact. These devices use compressed air, which can significantly reduce the carbon footprint compared to electric alternatives. However, it's essential to address the energy consumption associated with air compression. Compressed air systems can be energy-intensive, leading to higher operational costs.

When we examine energy levels, we find that inefficient systems can waste a substantial amount of electricity. Maintenance routines are crucial to ensuring optimal performance. Regular checks can help minimize leaks and improve energy efficiency, ultimately benefiting both the environment and the budget. Some industries may face challenges in maintaining these systems, leading to increased energy demands.

Moreover, while air actuators are versatile, they are not without drawbacks. The reliance on compressed air makes them vulnerable to supply fluctuations. Inconsistent air pressure can hinder performance and lead to unexpected downtime. Companies should reflect on these factors while integrating air actuators into their automation processes. Understanding both benefits and challenges can lead to better decision-making.

Related Posts

-

10 Essential Tips for Choosing the Right Air Actuator for Your Projects

-

Exploring Air Actuator Innovations at the 138th Canton Fair 2025 in China

-

The 7 Best Air Actuators for Enhanced Performance and Efficiency

-

Top 10 Uses of Air Actuator in Modern Technology?

-

How to Choose the Right Pneumatic Valve for Your Industrial Application

-

Revolutionizing Industrial Automation with Cutting-Edge Pneumatic Valve Actuators