Blog

Understanding the Benefits of Basket Strainers in Industrial Applications

In industrial applications, the use of basket strainers has become increasingly prevalent due to their critical role in preventing debris and contaminants from entering piping systems. According to industry reports, approximately 40% of equipment failures in various sectors can be attributed to particulate contamination, underscoring the need for effective filtration solutions.

Basket strainers serve as a first line of defense, offering a robust mechanism for filtering out unwanted solids from liquids and gases. Their design facilitates easy maintenance and efficient flow rates, making them ideal for a wide range of applications, including water treatment, petroleum refining, and chemical processing. With the global market for industrial filtration projected to reach $36.9 billion by 2025, the importance of reliable components like basket strainers cannot be overstated.

As industries continue to focus on operational efficiency and equipment longevity, understanding the benefits of basket strainers becomes paramount.

Basket strainers serve as a first line of defense, offering a robust mechanism for filtering out unwanted solids from liquids and gases. Their design facilitates easy maintenance and efficient flow rates, making them ideal for a wide range of applications, including water treatment, petroleum refining, and chemical processing. With the global market for industrial filtration projected to reach $36.9 billion by 2025, the importance of reliable components like basket strainers cannot be overstated.

As industries continue to focus on operational efficiency and equipment longevity, understanding the benefits of basket strainers becomes paramount.

Benefits of Basket Strainers: Enhancing Efficiency in Industrial Processes

Basket strainers play a vital role in enhancing efficiency within industrial processes by effectively removing debris from liquid streams. According to a report from the Filtration Society, the improper filtering of liquids can lead to equipment failures, resulting in up to 30% higher maintenance costs. By incorporating basket strainers, facilities can reduce the risk of blockages and ensure smoother operations. This proactive approach to filtering helps maintain continuous production flow, which is crucial in sectors such as oil and gas, water treatment, and chemical processing.

Furthermore, the American Society of Mechanical Engineers (ASME) estimates that implementing basket strainers can improve system efficiency by as much as 20% by minimizing downtime associated with cleaning and maintenance. As particulate matter accumulates in mechanical systems, the strainers capture unwanted contaminants, allowing for cleaner operation and reducing energy consumption. This efficiency not only translates to cost savings but also contributes to sustainability goals by lowering energy use and reducing waste, making basket strainers an indispensable component in modern industrial applications.

Key Industries Utilizing Basket Strainers: Insights from Market Data

Basket strainers play a crucial role in various industrial applications, providing effective filtration solutions to maintain system efficiency and prolong equipment lifespan. Key industries utilizing basket strainers include oil and gas, water treatment, and food processing, where the necessity for clean fluids and protection of downstream equipment is paramount. In the oil and gas sector, for instance, basket strainers are employed to filter out debris and particulates from crude oil and natural gas, ensuring that pumps and compressors operate smoothly and reducing the risk of costly downtime.

Market data reveals a growing trend in the adoption of basket strainers across these industries, driven by an increasing awareness of system reliability and maintenance cost reduction. In water treatment facilities, they are vital for removing larger solids from water before it undergoes further purification processes, safeguarding sensitive equipment from damage. Meanwhile, in the food processing industry, they help maintain high hygiene standards by filtering out contaminants, thus ensuring product safety and compliance with regulatory requirements. As industries continue to prioritize efficiency and safety, the demand for basket strainers is expected to rise, highlighting their importance in maintaining operational integrity.

Maintenance Cost Reduction and Longevity: Statistics Behind Basket Strainer Performance

Basket strainers are essential components in various industrial applications, effectively preventing debris from causing damage to pumps and other equipment. One of the most significant benefits they offer is a reduction in maintenance costs. By filtering out particles, basket strainers help maintain system efficiency and extend the lifespan of critical components. Statistics show that facilities using basket strainers experience up to a 30% decrease in maintenance frequency and associated costs, making them a cost-effective solution in the long run.

When selecting a basket strainer, consider the mesh size carefully. A finer mesh may trap more particles, but it can also lead to higher pressure drops and increased energy costs. Conversely, a larger mesh may allow harmful particles to pass through. Ensure to balance filtration needs with operational efficiency.

Another tip is to implement a regular inspection schedule. Timely cleaning and replacements not only enhance the performance of the strainer but also prevent unexpected breakdowns. Facilities that adopt this proactive approach often report a significant increase in system reliability and a notable decline in unplanned maintenance activities.

Improving Product Quality: The Role of Basket Strainers in Contaminant Filtration

Basket strainers play a crucial role in enhancing product quality across various industrial applications by effectively filtering out contaminants. They are designed to capture unwanted particles, which can vary from large debris to microscopic impurities, thereby safeguarding the integrity of the fluid system. According to a report by the American Filtration Society, systems equipped with basket strainers can decrease particle contamination levels by up to 95%, significantly mitigating the risk of product defects. This level of filtration is essential not only for operational efficiency but also for maintaining stringent industry standards.

The operational efficiency of industrial processes hinges on the purity of the materials being used. Studies indicate that even minor contaminant levels can lead to substantial quality issues, costing businesses both time and money. In the pharmaceutical sector, for example, a single batch of contaminated product can result in losses exceeding $1 million, as noted in findings from the Institute of Clean Manufacturing. By incorporating basket strainers, industries can ensure that contaminants are effectively eliminated before reaching critical points in production, thus upholding both compliance and quality assurance protocols.

Understanding the Benefits of Basket Strainers in Industrial Applications - Improving Product Quality: The Role of Basket Strainers in Contaminant Filtration

| Application Industry | Contaminants Filtered | Basket Strainer Material | Benefits | Maintenance Frequency |

|---|---|---|---|---|

| Chemical Processing | Dirt, Sand, Rust | Stainless Steel | Improved product purity | Monthly |

| Food and Beverage | Food particles, Fibers | Polypropylene | Enhanced quality control | Bi-weekly |

| Water Treatment | Algae, Debris | Carbon Steel | Prevention of clogging | Weekly |

| Pharmaceutical | Microorganisms, Particulates | 316L Stainless Steel | Compliance with regulations | Monthly |

| Oil and Gas | Sediments, Paraffin | Bronze | Extended equipment lifespan | Quarterly |

Safety and Compliance: How Basket Strainers Meet Industry Standards and Regulations

Basket strainers play a crucial role in ensuring safety and compliance in industrial applications by effectively filtering out debris and contaminants from liquids. According to a report from the International Association of Plumbing and Mechanical Officials (IAPMO), improper filtration can lead to equipment failure, resulting in costly downtime and safety hazards. By utilizing basket strainers, industries such as oil and gas, water treatment, and food processing can maintain the integrity of their systems while adhering to stringent industry standards.

In many jurisdictions, regulatory bodies mandate the use of filtration systems that comply with specific safety requirements. For example, the American National Standards Institute (ANSI) stipulates guidelines for filtration in various applications, emphasizing the necessity of integrating reliable straining mechanisms. A study from the World Health Organization (WHO) highlights that industries following these standards have reported a 30% decrease in maintenance costs and a significant reduction in accidents attributed to equipment malfunctions. Thus, the implementation of basket strainers not only aligns with regulatory compliance but also enhances operational efficiency and boosts overall safety in the workplace.

Understanding the Benefits of Basket Strainers in Industrial Applications

This bar chart illustrates the compliance of basket strainers with various industry standards and regulations, highlighting their importance in ensuring safety in industrial applications.

Related Posts

-

How to Choose the Right Basket Strainers for Your Industrial Needs

-

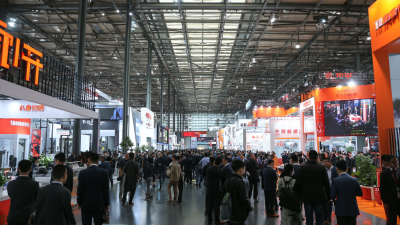

Exploring the Future of Basket Strainers at the 138th Canton Fair 2025 in China

-

Exploring Air Actuator Innovations at the 138th Canton Fair 2025 in China

-

Exploring Duplex Strainer Innovations at the 138th Canton Fair in 2025

-

Understanding Electric Actuators: Revolutionizing Automation in Modern Industries

-

Maximizing Operational Efficiency: The Role of Knife Gate Valves in Modern Industrial Applications