Blog

Understanding the Benefits of Butterfly Valves in Modern Industrial Applications

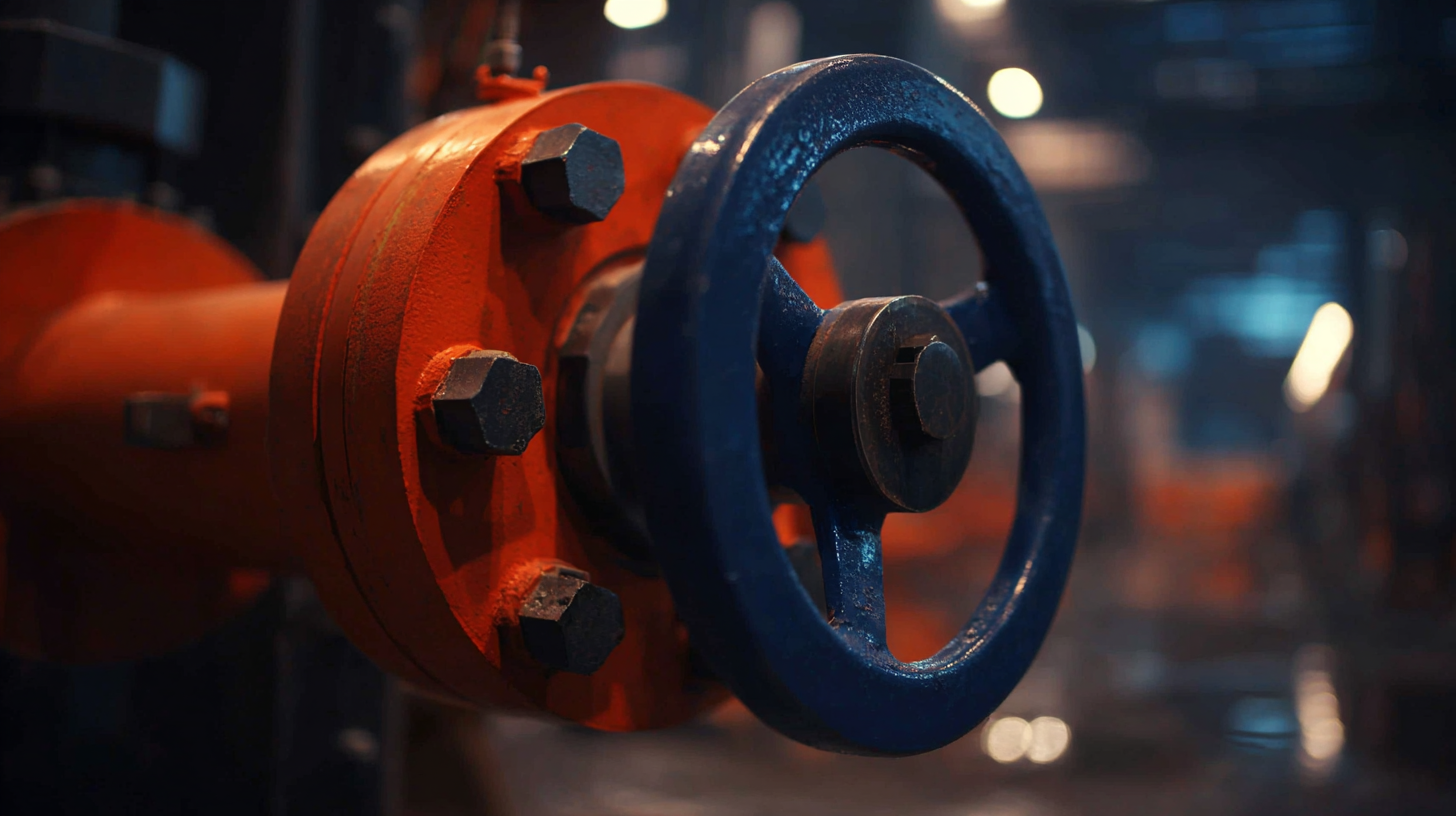

In the realm of modern industrial applications, the butterfly valve has emerged as a pivotal component due to its efficiency and versatility. According to a report by Global Market Insights, the global butterfly valve market is projected to surpass $8 billion by 2027, driven by increased demand across sectors such as water treatment, oil and gas, and power generation. The advantages of butterfly valves, including their lightweight design, quick operation, and cost-effectiveness, make them an attractive choice for various fluid control applications. As industries continue to evolve, these valves not only help in optimizing workflows but also contribute to sustainable practices by enhancing energy efficiency. Understanding the benefits and implementation strategies of butterfly valves is essential for engineers and decision-makers aiming to leverage cutting-edge solutions in their operations.

How to Choose the Right Butterfly Valve for Your Industrial Needs

When selecting the right butterfly valve for industrial applications, it’s essential to consider various factors that directly impact performance and efficiency. First, determine the type of fluid conveyed, as the compatibility of the valve material with the fluid is critical. For instance, rubber-lined valves are suitable for corrosive substances, while stainless steel valves perform well with neutral fluids.

Next, evaluate the pressure and temperature conditions of your system. Different butterfly valves are designed to withstand specific pressure and thermal ranges. It is vital to choose a valve that can operate effectively under the expected conditions to prevent failures. Additionally, consider the valve actuation method—manual, electric, or pneumatic—as it should align with the operational machinery and control systems in place. By taking these factors into account, industries can ensure the selection of butterfly valves that enhance their processes and maintain long-term reliability.

How to Ensure Optimal Performance of Butterfly Valves in Various Applications

To ensure optimal performance of butterfly valves in various applications, it is essential to focus on several key factors. First, proper selection of materials is crucial. Butterfly valves are commonly used in industries ranging from water treatment to chemical processing, and the materials chosen must withstand the specific operating conditions, including temperature, pressure, and corrosive environments. Choosing the right elastomers for seals and gaskets can also enhance the longevity and reliability of the valve.

Additionally, regular maintenance plays a significant role in maintaining performance. Users should establish a consistent inspection schedule to check for common issues such as wear and tear, misalignment, and tightness of the connections. Lubrication of moving parts and cleaning of the valve body help to prevent operational failures. Finally, integrating monitoring systems can provide valuable data on the valve’s performance, assisting in early detection of potential problems and facilitating timely interventions. By addressing these aspects, industries can ensure that their butterfly valves operate efficiently and effectively across various applications.

How to Maintain and Inspect Butterfly Valves for Long-Term Reliability

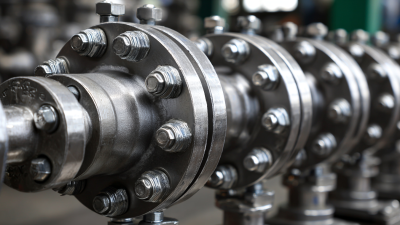

Regular maintenance and inspection of butterfly valves are crucial for ensuring their long-term reliability in industrial applications. According to a report by the Flow Control Institute, nearly 30% of valve failures in process industries are attributable to inadequate maintenance practices. Regular inspection intervals are recommended every 6 to 12 months, depending on the operational environment. During these inspections, technicians should assess the valve’s operation, check for leaks, and ensure that the seating surfaces are free from debris. This vigilance can prevent costly downtimes and maintain optimal performance.

Proper lubrication is another essential aspect of butterfly valve maintenance. The American Society of Mechanical Engineers (ASME) highlights that well-lubricated valves operate smoothly and prolong their lifespan by reducing friction. Manufacturers suggest using specific lubricants compatible with the valve materials to avoid chemical reactions that could lead to premature failure. Additionally, it's important to regularly check the actuator mechanisms, as about 25% of issues can stem from actuator malfunction. By implementing a structured maintenance program and adhering to industry best practices, facilities can enhance the reliability and efficiency of butterfly valves in their systems.

Understanding the Benefits of Butterfly Valves in Modern Industrial Applications - How to Maintain and Inspect Butterfly Valves for Long-Term Reliability

| Dimension | Description | Benefits | Maintenance Tips |

|---|---|---|---|

| Flow Control | Regulates the flow of liquids and gases in various systems. | Improved process efficiency and reduced energy costs. | Regularly check for wear on seals; ensure full closure and operation. |

| Compact Design | Takes up less space compared to other valve types. | Ideal for applications with limited space. | Inspect for any misalignments during routine checks. |

| Versatility | Can be used in various applications across multiple industries. | Suits a wide range of media including corrosive fluids. | Check compatibility with fluids before installation. |

| Cost-Effectiveness | Lower initial and maintenance costs compared to other valves. | Makes them a budget-friendly option for many applications. | Keep a log of maintenance activities to manage costs. |

| Quick Operation | Fast opening and closing action minimizes downtime. | Enhances overall system responsiveness. | Test actuation speed as part of routine inspections. |

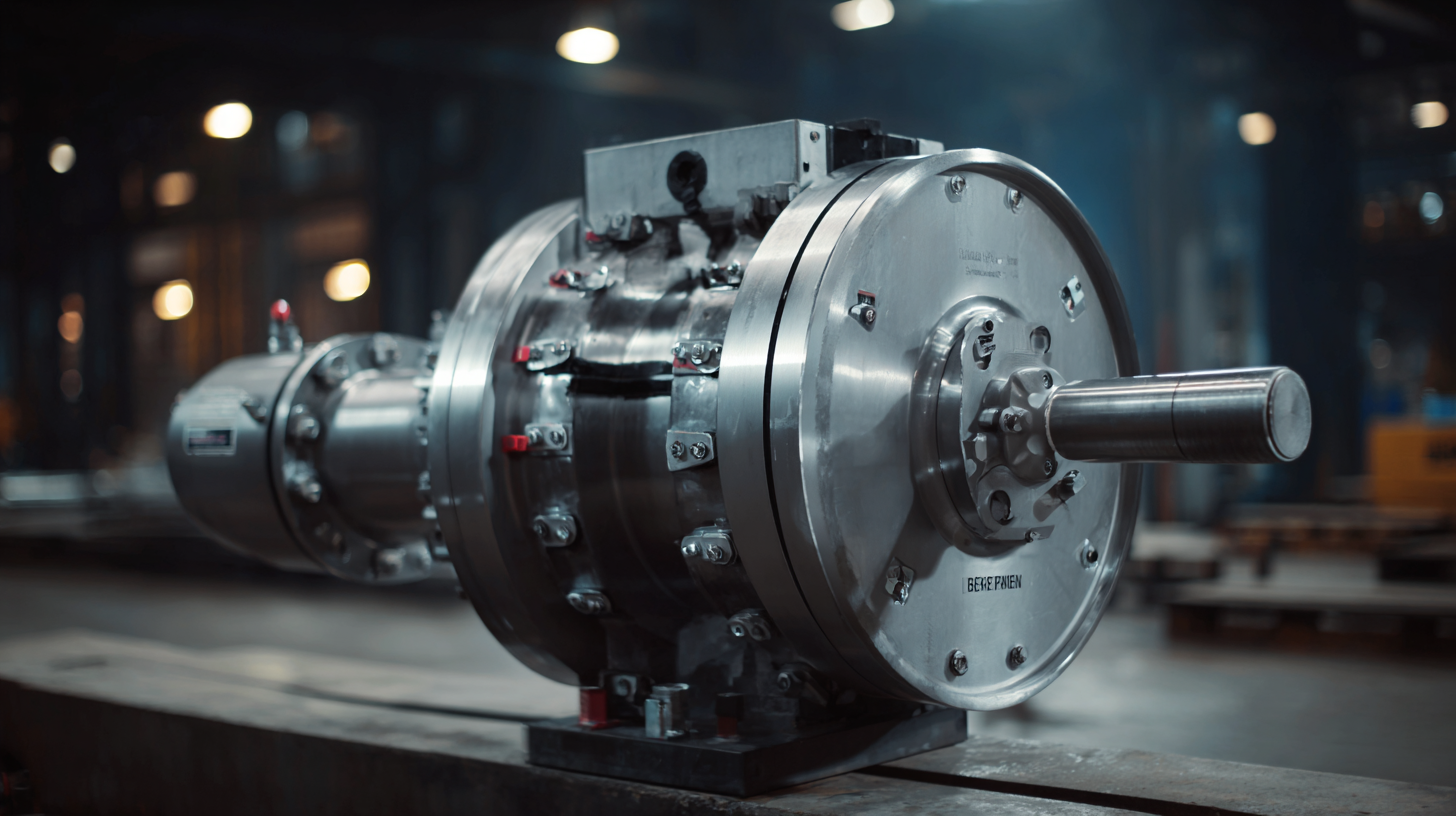

How to Integrate Butterfly Valves into Modern Pipe Systems Effectively

Integrating butterfly valves into modern pipe systems requires a thoughtful approach that maximizes their efficiency and effectiveness. According to a report by MarketsandMarkets, the global butterfly valve market is projected to grow from $6.78 billion in 2021 to $9.71 billion by 2026, reflecting a compound annual growth rate (CAGR) of 7.5%. This growth highlights the increasing reliance on these valves in various industrial applications, including water treatment, oil and gas, and food processing. To effectively integrate butterfly valves, engineers must prioritize the correct sizing and selection based on the specific requirements of the system, including flow rate, pressure ranges, and the type of media being transported.

Effective integration also involves utilizing modern technologies such as 3D modeling and simulation software. According to a study by the International Journal of Engineering Research and Applications, incorporating these tools can enhance design accuracy and streamline the installation process, reducing downtime by up to 30%. Additionally, proper maintenance schedules should be established to ensure optimal performance. Regular inspections and servicing can prevent common issues such as wear and tear, resulting in increased reliability and operational efficiency. Emphasizing these aspects will not only improve the overall functionality of pipe systems but also contribute to the longevity and cost-effectiveness of industrial operations.

How to Troubleshoot Common Issues with Butterfly Valves in Industry

In modern industrial applications, butterfly valves are widely recognized for their efficiency and versatility in controlling fluid flow. However, like any mechanical component, they are susceptible to common issues that can affect performance. Troubleshooting these issues may involve examining factors such as valve alignment, actuator functionality, and seal integrity. Regular maintenance and careful monitoring can preempt many problems, ensuring smooth operation.

Tips for maintaining butterfly valves include:

- Regularly inspect and lubricate the valve seals to prevent friction and wear.

- Verify the alignment of the valve with the piping system to avoid binding and operational failures.

- Check for leaks around the valve body, which can indicate a need for seal replacement.

Furthermore, recent innovations in valve design have addressed industry challenges, such as the scaling issues seen in geothermal control valves. Reports indicate that the industrial valve market is expanding, with projections highlighting significant growth driven by the need for reliable fluid control. As industries strive for efficiency, understanding how to troubleshoot and maintain butterfly valves becomes increasingly critical to operational success.

Understanding the Benefits of Butterfly Valves in Modern Industrial Applications

This chart illustrates the common issues encountered with butterfly valves in various industrial applications, along with their frequencies of occurrence. The data provides insights into areas that may require troubleshooting to enhance performance and reliability.

Related Posts

-

How to Select the Best Butterfly Valve Type for Your Industrial Needs

-

Exploring Duplex Strainer Innovations at the 138th Canton Fair in 2025

-

How to Choose the Right Basket Strainers for Your Industrial Needs

-

How to Choose the Right Pneumatic Valve for Your Industrial Application

-

Understanding the Importance of Spring Check Valve in Modern Plumbing Systems

-

Revolutionizing Industrial Automation with Cutting-Edge Pneumatic Valve Actuators