Blog

Top 5 Benefits of Using Pneumatic Butterfly Valves in Industrial Applications

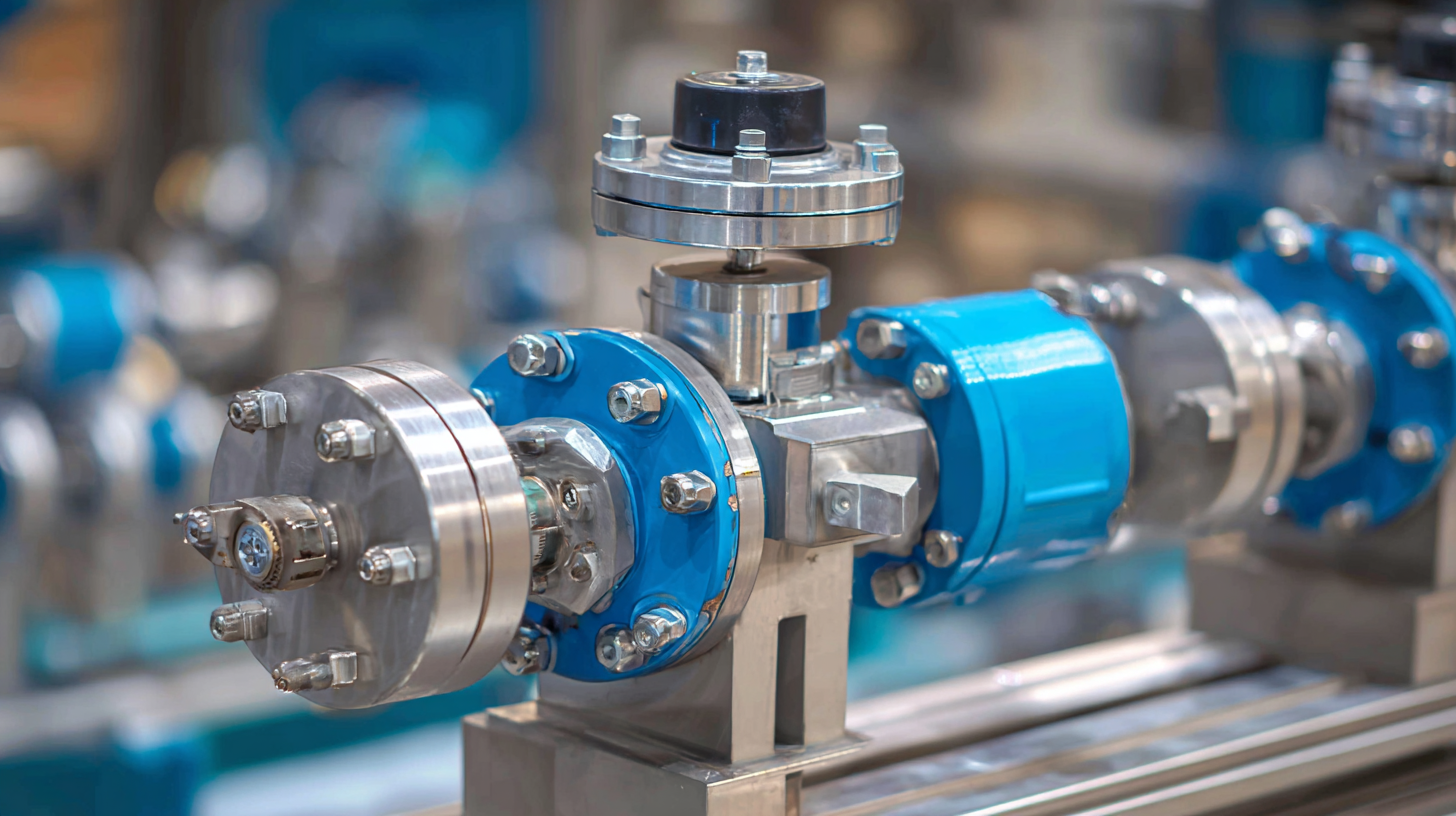

In the dynamic landscape of industrial applications, efficiency and reliability remain paramount. Among the various components that facilitate optimal operational performance, the pneumatic butterfly valve has emerged as a crucial element. According to the Global Butterfly Valve Market Report, the demand for butterfly valves, particularly pneumatic variants, is anticipated to surge, with an expected growth rate of over 5% annually through 2025. This trend underscores the increasing recognition of pneumatic butterfly valves for their role in enhancing process control across diverse sectors, including oil and gas, water treatment, and chemical manufacturing.

The benefits of using pneumatic butterfly valves extend beyond mere operational efficiency. Their design allows for quick and precise control of flow, making them ideal for applications where responsiveness is critical. In a report by the International Institute of Industrial Workflow Control, it was noted that pneumatic butterfly valves contribute to reducing energy consumption by up to 20% compared to traditional valve types. Furthermore, their lightweight structure and simple installation contribute to decreased maintenance costs and improved service life, making them an economically viable choice for industries striving for sustainability and cost-effectiveness. As we dive into the top five benefits of using pneumatic butterfly valves, it becomes evident that they not only meet contemporary industrial demands but also pave the way for innovative advancements in workflow management.

Enhanced Flow Control Efficiency: Assessing Performance Metrics of Pneumatic Butterfly Valves in Fluid Dynamics

Pneumatic butterfly valves are pivotal in enhancing flow control efficiency within various industrial applications. Their design allows for rapid opening and closing, resulting in superior responsiveness to fluctuating flow rates. This swift actuation effectively minimizes pressure drops, ensuring that the maximum volume of fluid can pass through with minimal resistance. In fluid dynamics, this translates to improved performance metrics, particularly in applications where precise flow regulation is critical.

The performance of pneumatic butterfly valves can be quantified through various metrics such as flow coefficient (Cv) and flow rate adjustment. These valves exhibit a linear response across a range of pressures, providing operators with predictable and consistent control over fluid dynamics. Additionally, their lightweight construction reduces the energy required for actuation, further enhancing overall operational efficiency. As industries increasingly prioritize sustainable practices, the adoption of pneumatic butterfly valves will likely rise, driven by their ability to optimize system performance while reducing energy consumption.

Significant Reduction in Energy Consumption: Industry Statistics on Pneumatic Valve Systems

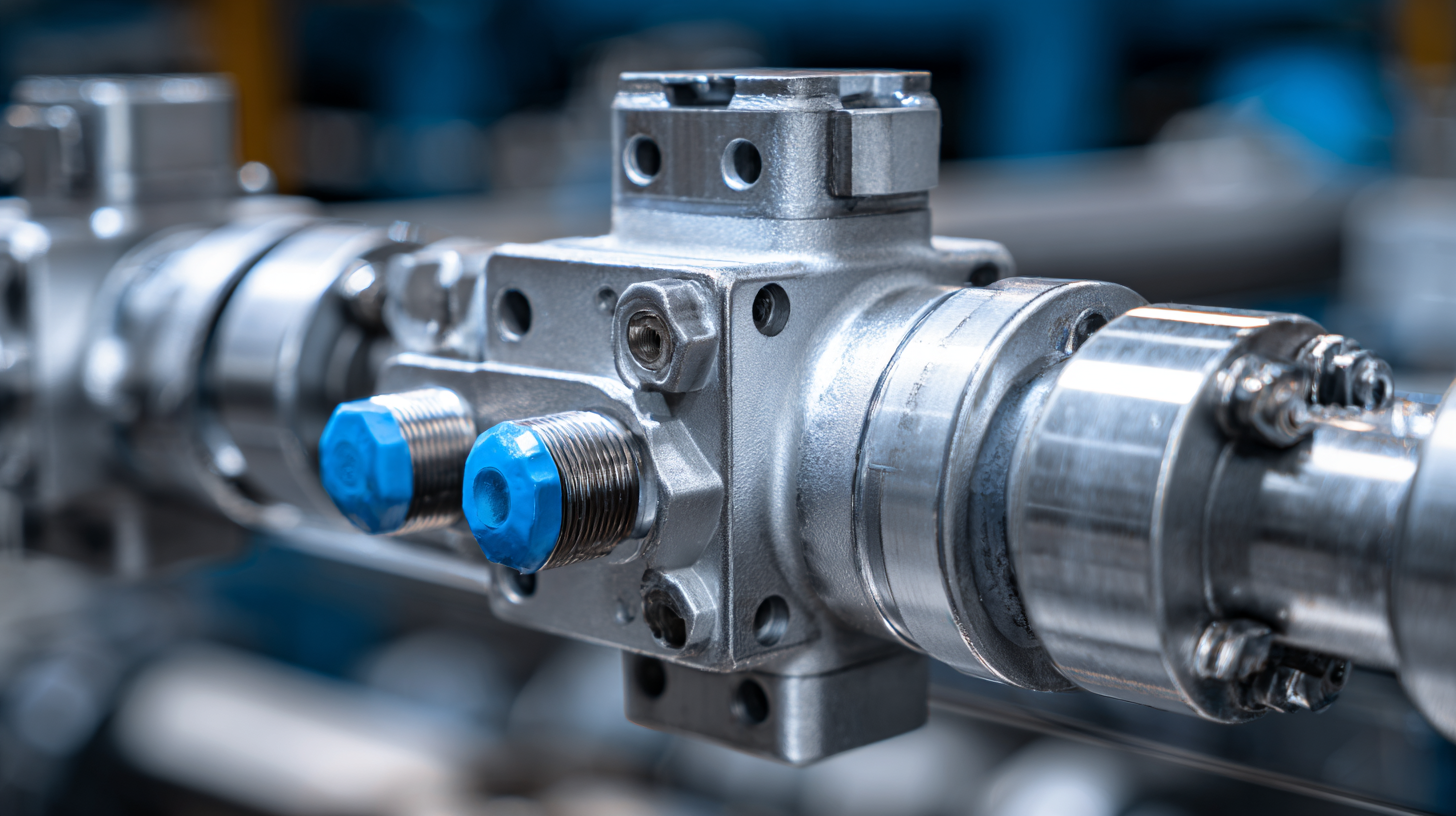

Pneumatic butterfly valves have gained popularity in various industrial applications, primarily due to their significant reduction in energy consumption. Industry statistics reveal that these valves can optimize operational efficiency, leading to lower energy costs for businesses. By utilizing compressed air for actuation, pneumatic butterfly valves require less energy to operate compared to traditional valve systems, translating to substantial savings over time. This energy efficiency is particularly crucial in industries where energy costs represent a significant portion of operational expenses.

Furthermore, the integration of pneumatic valve systems can enhance process control and reduce downtime. With faster opening and closing times, these valves improve the overall responsiveness of the system, thereby optimizing production rates. A study showed that facilities using pneumatic systems experienced a 15% reduction in energy use compared to those using manual or electric alternatives. This not only streamlines operations but also contributes to a more sustainable industrial environment by decreasing the carbon footprint associated with energy consumption. As industries continue to seek more efficient solutions, pneumatic butterfly valves stand out as a pivotal technology for achieving energy efficiency and operational excellence.

Improved Safety Standards: Evaluating the Impact of Pneumatic Butterfly Valves on Industrial Safety Metrics

Pneumatic butterfly valves are increasingly recognized for their significant role in enhancing industrial safety standards. By providing precise control over fluid flow and pressure, these valves help minimize the risks associated with leaks and over-pressurization. In industries where hazardous materials are handled, the ability to quickly shut off flow in emergency situations is vital. Pneumatic actuation allows for rapid response times that manual valves simply cannot match, adding an essential layer of protection for both personnel and equipment.

When implementing pneumatic butterfly valves, it's important to ensure proper installation and maintenance. Regular inspections can help identify potential issues before they escalate, helping maintain operational integrity. Additionally, training staff on the proper use of these valves can significantly reduce the likelihood of human error during critical operations.

Another tip for enhancing safety is utilizing remote monitoring systems linked to the pneumatic valves. This technology allows operators to keep tabs on valve performance in real-time, ensuring they are functioning correctly and minimizing the chance of unsafe conditions developing unnoticed. This proactive approach not only protects workers but also contributes to a safer overall work environment.

Cost-Effectiveness Analysis: Comparing Long-Term Savings with Pneumatic vs. Traditional Valve Solutions

Pneumatic butterfly valves have gained traction in industrial applications due to their numerous advantages, particularly in cost-effectiveness compared to traditional valve solutions. A recent report from the International Society of Automation (ISA) indicates that the total cost of ownership of pneumatic butterfly valves can be up to 25% lower than that of traditional gate or globe valves over a 10-year period. This reduction is largely attributed to lower maintenance requirements and improved energy efficiency, resulting in considerable long-term savings for businesses.

Moreover, the efficiency of pneumatic systems plays a critical role in operational costs. According to estimates from the Valve Manufacturers Association (VMA), pneumatic valves can operate at nearly 90% efficiency, which significantly reduces the energy consumption associated with valve actuation. In scenarios where large volumes of fluids are transported, switching to pneumatic butterfly valves can yield savings upwards of 30% in energy costs alone. Such compelling data emphasizes the financial viability of pneumatic solutions, making them a strategic investment for industries looking to enhance both performance and sustainability in their operations.

Cost-Effectiveness Analysis: Pneumatic vs. Traditional Valve Solutions

Versatility in Application: Data-Driven Insights on Industry Adoption Across Various Sectors

Pneumatic butterfly valves have gained significant traction across various industrial sectors due to their versatility and efficiency in handling a wide range of applications. Industries such as water treatment, food and beverage, and chemical manufacturing have increasingly adopted these valves for their ability to provide quick and precise control over fluid flow. Data-driven insights reveal that in sectors where space and weight are crucial, the compact design of pneumatic butterfly valves allows for seamless integration into existing systems, minimizing installation challenges.

Moreover, the adaptability of pneumatic butterfly valves extends to diverse media types, whether dealing with corrosive chemicals or high-viscosity liquids. Their design enables operations in extreme conditions, making them suitable for applications requiring high levels of automation and reliability. As industries continue to prioritize efficiency and cost-effectiveness, the shift towards pneumatic butterfly valves highlights the growing need for equipment that can perform well under pressure while maintaining operational flexibility. This trend illustrates the increasing recognition of pneumatic butterfly valves as essential components in the pursuit of optimized industrial processes.

Top 5 Benefits of Using Pneumatic Butterfly Valves in Industrial Applications - Versatility in Application: Data-Driven Insights on Industry Adoption Across Various Sectors

| Industry Sector | Adoption Rate (%) | Primary Application | Operational Efficiency Improvement (%) | Cost Savings (%) |

|---|---|---|---|---|

| Oil & Gas | 75 | Flow Control | 20 | 15 |

| Water Treatment | 60 | Isolation | 25 | 10 |

| Chemical Processing | 80 | Mixing and Flow Regulation | 30 | 20 |

| Food and Beverage | 70 | Sanitary Flow Control | 15 | 12 |

| HVAC Systems | 65 | Airflow Management | 18 | 8 |

Related Posts

-

Exploring the Future of Control Valves in Sustainable Industrial Applications

-

Understanding Electric Actuators: Revolutionizing Automation in Modern Industries

-

Exploring the Future of Basket Strainers at the 138th Canton Fair 2025 in China

-

Understanding the Importance of Spring Check Valve in Modern Plumbing Systems

-

Understanding the Benefits of Butterfly Valves in Modern Industrial Applications

-

Exploring Duplex Strainer Innovations at the 138th Canton Fair in 2025