Blog

The 7 Best Air Actuators for Enhanced Performance and Efficiency

In today's fast-paced industrial environment, the pursuit of enhanced performance and efficiency has become a top priority for manufacturers and engineers alike. One crucial component that can significantly impact these objectives is the air actuator. Known for their versatility and reliability, air actuators play a vital role in various applications, from automation systems to material handling processes. Their ability to convert compressed air into mechanical motion enables businesses to streamline operations and improve productivity.

As we delve into the best air actuators available in the market, it’s essential to consider their performance characteristics, energy efficiency, and ease of integration into existing systems. Selecting the right air actuator can lead to optimized control, quicker response times, and ultimately, cost savings. This guide will explore seven of the best air actuators, highlighting their features and benefits, while assisting you in making an informed choice that aligns with your operational needs. By understanding the capabilities of these pneumatic devices, you can elevate your system's performance and efficiency to new heights.

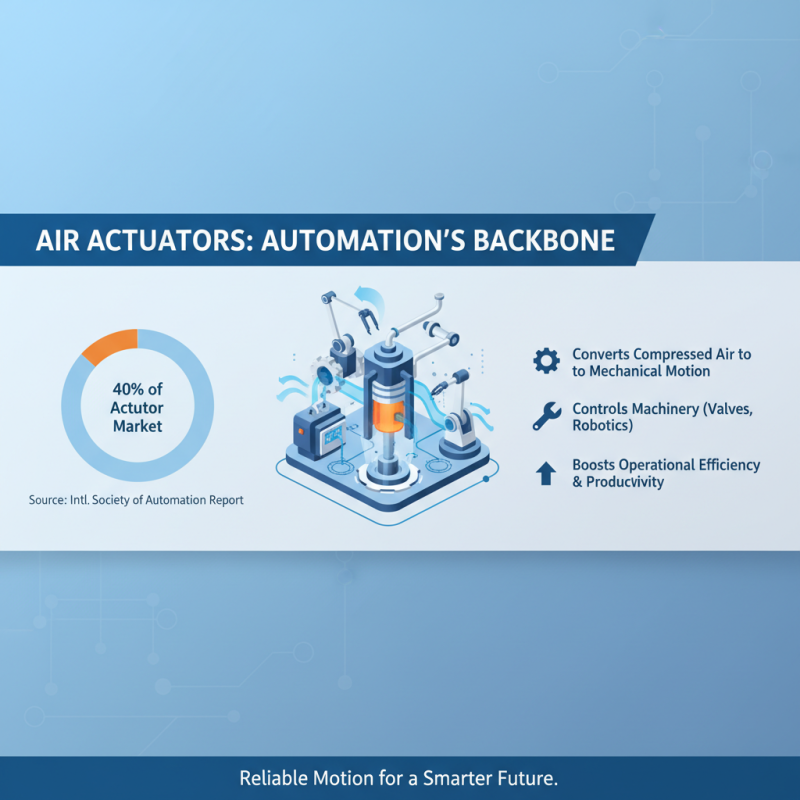

Overview of Air Actuators and Their Importance in Automation

Air actuators have become an integral part of automation systems across various industries, serving as the backbone of efficient operations. By converting compressed air into mechanical motion, these devices provide a reliable means of controlling machinery, ranging from simple valve operations to complex robotic systems. According to a report from the International Society of Automation, air actuators account for approximately 40% of the actuator market, underscoring their significance in enhancing operational efficiency and productivity in numerous applications.

When selecting air actuators, it’s essential to consider factors such as response time, load capacity, and energy consumption. Research indicates that modern air actuators can operate with up to 20% greater efficiency while also reducing energy costs, leading to lower operational expenses. In an industry where uptime and speed are critical, air actuators can significantly reduce the time required for processes, offering companies a competitive edge in the market.

Tips: Regular maintenance of air actuators can ensure optimal performance and longevity. Additionally, opting for actuators with adjustable stroke lengths can provide versatility in various applications, accommodating a range of tasks without compromising on precision. Lastly, investing in quality filtration systems for your compressed air supply can enhance the reliability and efficiency of your air actuators, minimizing potential downtime due to contamination.

Key Features to Consider When Choosing Air Actuators

When selecting air actuators for improved performance and efficiency, several key features should be prioritized. Firstly, the actuator's response time is crucial. According to industry reports, faster response times can lead to significant improvements in automation processes, with some applications experiencing a 30% increase in productivity by utilizing actuators with response times under 50 milliseconds. Additionally, the actuator's load capacity and stroke length must be evaluated to ensure compatibility with your specific application requirements. A well-chosen actuator can maximize operational efficiency, especially in high-demand environments.

Another important aspect to consider is the type of materials used in the construction of the actuator. High-grade materials can enhance durability and resistance to wear, which is essential in preventing unexpected downtimes and prolonging the lifespan of equipment. Data shows that actuators made from corrosion-resistant materials can reduce maintenance costs by up to 20%, making them a worthwhile investment for many industries.

Tips: When choosing an air actuator, ensure to evaluate the environmental conditions it will operate in. Extreme temperatures or exposure to harsh chemicals can impact performance. Additionally, always verify the actuator's compatibility with your existing systems to avoid costly adjustments later on. Regularly scheduled maintenance checks can also optimize the performance of air actuators, ensuring they operate at peak efficiency for as long as possible.

Top 7 Air Actuators for Performance Improvement and Efficiency

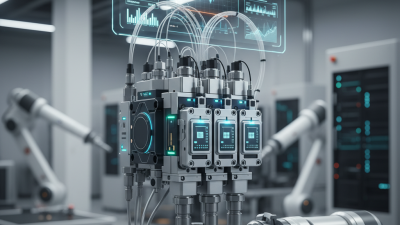

Air actuators are increasingly recognized for their pivotal role in enhancing operational performance and boosting efficiency across various industries. According to a recent report by MarketsandMarkets, the global pneumatic actuators market is projected to reach $10.7 billion by 2026, indicating a significant rise in demand for air-powered solutions. This trend highlights the value of pneumatic technology in achieving faster response times and reducing energy consumption during processes like material handling and automation.

Furthermore, advancements in air actuator design have led to improved energy efficiency and reliability. Many modern air actuators now feature integrated sensors and smart components that optimize performance based on real-time data. For example, a study published in the Journal of Modern Manufacturing Technologies emphasized that energy savings of up to 30% can be achieved with automated pneumatic systems compared to traditional mechanisms. As industries strive towards sustainability, the shift towards air actuators not only brings about cost savings but also aligns with environmental goals by reducing energy usage and minimizing carbon footprints effectively.

Comparative Analysis of Air Actuators: Performance Metrics and Costs

When it comes to optimizing performance and efficiency in industrial applications, the choice of air actuators can significantly impact operational effectiveness. A comparative analysis focusing on performance metrics reveals that parameters such as response time, cycle rate, and payload capacity should be carefully evaluated. According to a recent industry report by the International Society of Automation, the best air actuators on the market today demonstrate a typical response time of less than 100 milliseconds, enhancing productivity levels by up to 25%. This is particularly crucial in environments where precision and speed are paramount.

In terms of costs, it is essential to consider not only the initial purchase price but also the total cost of ownership, including maintenance and energy consumption. A thorough analysis has shown that high-quality air actuators may have a higher upfront cost but can lead to savings of approximately 15% in energy bills and reduced maintenance expenses over time. Additionally, organizations should assess the suitability of different actuator types, such as double-acting versus single-acting models, based on their specific applications to ensure efficient resource utilization.

Tip: When selecting air actuators, always review the manufacturer's performance data and testimonials from existing customers. This can provide practical insights and help in making informed decisions that align with your operational needs. Evaluate potential setups in a pilot environment to track performance and costs effectively before full implementation.

Future Trends in Air Actuators and Technological Advancements

The landscape of air actuators is rapidly evolving, with technological advancements leading the way for enhanced performance and efficiency. One of the most notable trends is the integration of smart technologies, allowing for real-time monitoring and feedback. This not only improves operational efficiency but also facilitates predictive maintenance, reducing downtime and extending the lifespan of the actuators. Through data analytics and IoT connectivity, users can optimize their systems dynamically, leading to significant energy savings and improved accuracy in various applications.

When considering air actuators, it is vital to stay ahead of the curve. **Tips**: First, always assess the specific needs of your application before choosing an actuator type. Different sectors, such as automation, robotics, and automotive, have unique requirements that may influence actuator selection. Secondly, keep an eye on emerging technologies like advanced materials and miniaturization, which promise to enhance actuator performance and reduce weight without sacrificing strength.

Additionally, sustainability is becoming a focal point in the development of air actuators. Manufacturers are experimenting with eco-friendly materials and energy-efficient designs that minimize environmental impact while maximizing performance. **Tips**: Invest in actuators that not only meet your operational needs but also align with sustainability goals. This can lead to improved public perception and compliance with new regulations aimed at reducing carbon footprints across industries.

The 7 Best Air Actuators for Enhanced Performance and Efficiency - Future Trends in Air Actuators and Technological Advancements

| Model | Operating Pressure (psi) | Stroke Length (in) | Response Time (ms) | Efficiency (%) |

|---|---|---|---|---|

| Model A | 80 | 4 | 50 | 95 |

| Model B | 90 | 6 | 45 | 92 |

| Model C | 75 | 8 | 60 | 90 |

| Model D | 100 | 5 | 30 | 98 |

| Model E | 85 | 7 | 55 | 93 |

| Model F | 70 | 6 | 65 | 89 |

| Model G | 95 | 4 | 40 | 94 |

Related Posts

-

10 Essential Tips for Choosing the Right Air Actuator for Your Projects

-

Exploring Air Actuator Innovations at the 138th Canton Fair 2025 in China

-

Revolutionizing Industrial Automation with Cutting-Edge Pneumatic Valve Actuators

-

Exploring the Future of Pneumatic Control Valves in 2025 Top Digital Innovations

-

Understanding the Benefits of Basket Strainers in Industrial Applications

-

How to Choose the Right Basket Strainers for Your Industrial Needs