Blog

2026 Best Hydraulic Actuator Types for Your Project Needs?

In the evolving landscape of industrial applications, the role of hydraulic actuators continues to be pivotal. By 2026, hydraulic actuator market growth is expected to reach a staggering $20 billion, driven by their efficiency and reliability. These devices serve as the backbone for machinery in various sectors, including automotive, aerospace, and manufacturing. With their ability to handle heavy loads and provide precise control, hydraulic actuators are essential in achieving optimal performance in many projects.

However, not all hydraulic actuators are created equal. Different types serve different needs, leading to potential mismatches in project applications. The selection of the right hydraulic actuator can make or break a project. Is a linear actuator more suitable than a rotary type? This question often remains unaddressed. Many professionals overlook the nuances of actuator types, which can lead to inefficiencies and increased costs down the line.

Choosing the best hydraulic actuator requires careful consideration of specifications, application requirements, and integration capabilities. Understanding these aspects is crucial for project success. Without this insight, projects might face delays and operational challenges. As we approach 2026, the need for informed decisions in hydraulic actuator selection has never been more urgent.

Types of Hydraulic Actuators and Their Applications in Various Industries

Hydraulic actuators are vital in various industries, powering critical machinery. These devices convert hydraulic energy into mechanical motion. Their applications range from manufacturing to aerospace. In fact, a report from the International Hydraulics Association reveals that the hydraulic actuator market is projected to grow by over 5% annually until 2026. This growth reflects the increasing demand for efficiency in industrial processes.

Different types of hydraulic actuators serve distinct purposes. Cylinders are the backbone of many operations, providing linear motion. These cylinders come in various sizes, tailored to specific tasks. For example, small cylinders might be used in robotics, while larger ones are essential in construction equipment. Then there are hydraulic motors. They offer rotational movement and play a crucial role in conveyor systems. The diverse applications highlight the versatility of these actuators.

However, while the capabilities of hydraulic actuators are impressive, there are challenges. Leaks and maintenance issues can hinder performance. Additionally, improper sizing for specific applications often leads to inefficiencies. This can result in increased operating costs. Awareness of these challenges is essential for successful implementation. Understanding the specific requirements of your project can lead to better actuator selection.

2026 Best Hydraulic Actuator Types for Your Project Needs

| Actuator Type | Description | Applications | Advantages | Limitations |

|---|---|---|---|---|

| Linear Hydraulic Actuator | Provides straight-line motion for various operations. | Construction, Manufacturing, Aerospace | High force output, Simple design | Requires hydraulic fluid, Risk of leakage |

| Rotary Hydraulic Actuator | Converts hydraulic pressure into rotational motion. | Robotics, Automotive, Marine | Compact design, Smooth operation | Limited rotation range, More complex control |

| Double-Acting Actuator | Utilizes hydraulic pressure on both sides of the piston. | Heavy machinery, Agricultural equipment | Higher efficiency, Better control | Higher initial cost, More complex installation |

| Single-Acting Actuator | Uses hydraulic pressure on one side only. | Lifts, Dumps, Opening/Closing Doors | Simpler design, Cost-effective | Slower return stroke, Less efficient |

Key Factors to Consider When Selecting Hydraulic Actuators for Projects

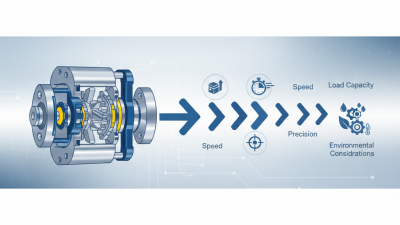

When selecting hydraulic actuators, several key factors must be considered. The application type greatly impacts your choice. For example, the required force, speed, and precision may vary across different projects. According to industry reports, approximately 60% of hydraulic failures stem from improper actuator selection. A thorough understanding of load demands is vital to avoid costly downtime.

Another crucial aspect is the working environment. Actuators are often exposed to harsh conditions. Temperature fluctuations, moisture, and contaminants can affect performance. Research notes that nearly 30% of hydraulic equipment failures are due to environmental factors. It's essential to choose actuators with suitable seals and materials for durability. Ignoring these details can lead to premature wear and operational issues.

Integration with existing systems is also important. Hydraulic systems can be complex, and compatibility plays a significant role in efficiency. Discrepancies in sizing or specifications can lead to decreased performance. In a recent survey, over 40% of engineers reported challenges with integration. It's a reminder to examine how new components will function within the current setup before making decisions. These considerations can help ensure project success.

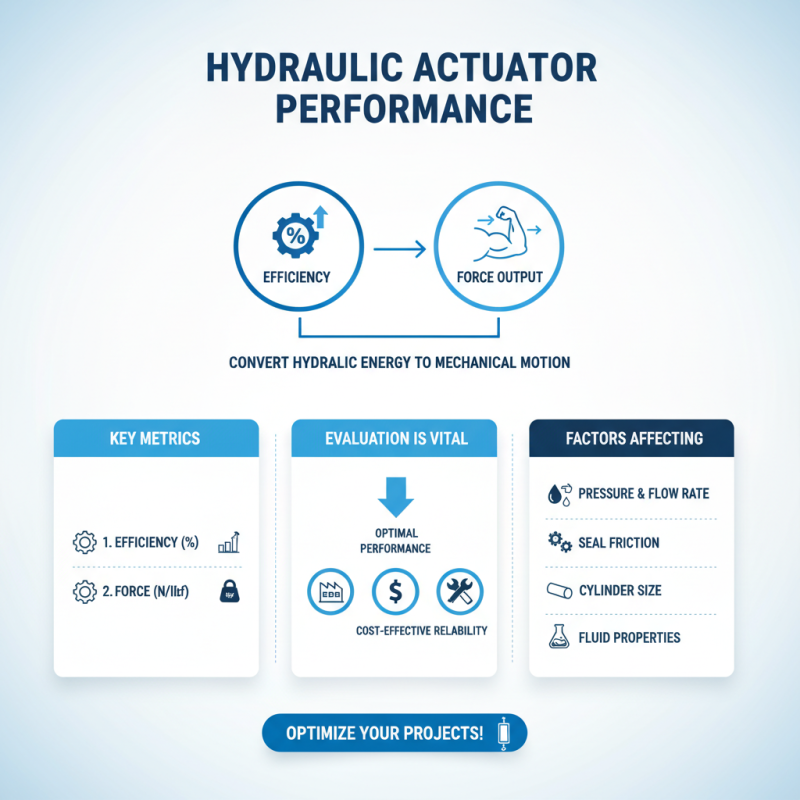

Performance Metrics: Assessing Actuator Efficiency and Force Output

Hydraulic actuators are essential in many projects. They convert hydraulic energy into mechanical motion. Evaluating their efficiency and force output is vital for optimal performance. You need to consider various factors affecting these metrics.

One primary factor is the actuator's design. A well-designed actuator maximizes force while minimizing energy loss. Do thorough tests before making a decision. Understanding the load requirements and speed needs is essential. It influences the actuator's selection significantly.

**Tip:** Always run simulations to measure performance before installation. Testing different configurations can reveal hidden inefficiencies.

Force output varies based on hydraulic pressure. A higher pressure often increases force but may also lead to overheating. Balance is key. Strive for a setting that maintains efficiency without compromising longevity.

**Tip:** Monitor temperature regularly to avoid damage. This simple practice can prolong the actuator's life. Remember, efficiency always requires fine-tuning and adjustments.

Emerging Technologies in Hydraulic Actuation for Enhanced Precision

Emerging technologies in hydraulic actuation are changing how industries approach automation. New materials and improved designs are making actuators lighter yet stronger. According to a recent industry report, precision in hydraulic systems can increase efficiency by up to 30%. This transformation is vital in sectors like aerospace and manufacturing where precise control is critical.

Innovations in sensor integration are enhancing the monitoring of fluid dynamics. Advanced feedback mechanisms enable real-time adjustments, ensuring accuracy. A study highlighted that systems utilizing advanced sensors could lead to a 25% decrease in energy consumption. However, these technologies come with challenges. Implementation can be costly, and integration into existing frameworks may require substantial effort.

The growing trend towards electrification is noteworthy. Electrically controlled hydraulic systems are gaining popularity for their responsiveness. Yet, some experts caution that these systems might not perform well in harsh environments. There’s a need for further research to balance these innovations with practical constraints. The pursuit of enhanced precision in hydraulic actuation is ongoing, as industries adapt and evolve.

Comparative Analysis of Cost-Effectiveness in Hydraulic Actuators

When selecting hydraulic actuators, cost-effectiveness is a crucial factor. The global hydraulic actuator market is expected to reach $23 billion by 2026, driven by increasing demand in various industries, such as manufacturing and aerospace. A recent report revealed that pneumatic actuators are often less expensive upfront, yet hydraulic actuators provide higher force and speed for the same investment.

Consider the total cost of ownership. Hydraulic systems may require more initial investment, yet they often outperform pneumatic alternatives in durability. A study indicated that hydraulic systems endure roughly 30% longer than pneumatic systems under similar conditions. This longevity can reduce replacement costs and maintenance, making hydraulic options more appealing in the long run.

However, not all projects benefit from a hydraulic solution. In smaller applications, the complexity and installation costs of hydraulic systems can outweigh their advantages. Decision-makers must weigh these factors carefully, as a poor choice can lead to inefficiencies. Evaluating the specific needs of your project is essential to make a truly informed decision, balancing between upfront costs and lifetime performance.

Related Posts

-

Understanding Hydraulic Actuators: How They Improve Efficiency in Industrial Automation by 30%

-

Understanding the Importance of Spring Check Valve in Modern Plumbing Systems

-

Top 10 Hydraulic Actuators: Boost Your Machinery Efficiency Today

-

2025 Guide: How to Choose the Right Hydraulic Rotary Actuator for Your Needs

-

Understanding Electric Actuators: Revolutionizing Automation in Modern Industries

-

10 Essential Tips for Choosing the Right Air Actuator for Your Projects