Blog

Top 5 Best Motorized Valves for Efficient Flow Control?

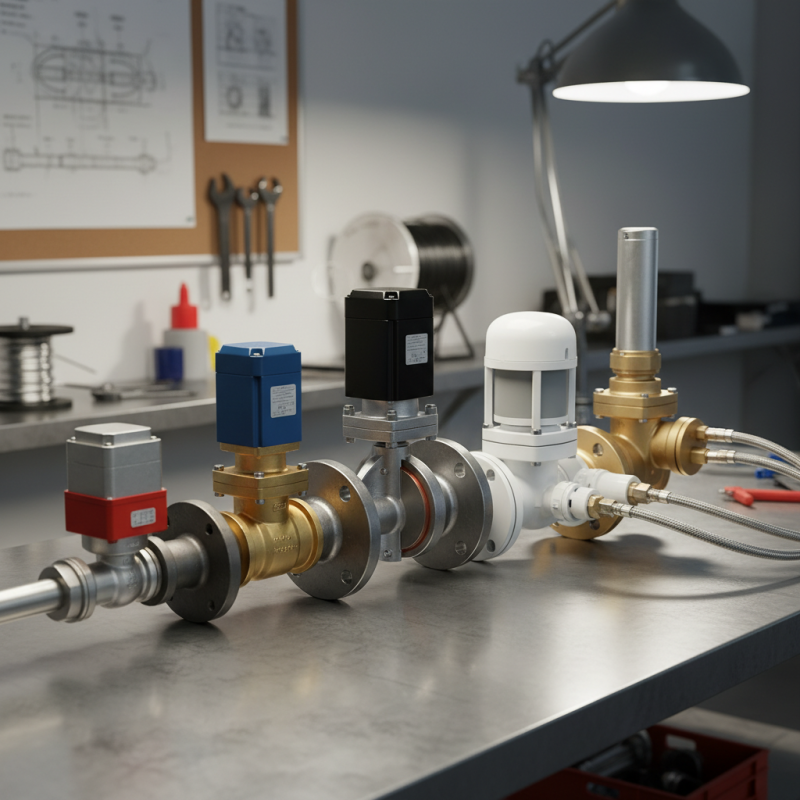

In the realm of flow control, motorized valves play a crucial role. Experts in the industry emphasize their importance. For instance, Dr. Emily Carter, a renowned engineer, once stated, "Motorized valves are essential for precise flow management in modern systems." This highlights how vital they are in various applications.

Choosing the right motorized valve is not simple. There are numerous options, and each has its unique features. A perfect choice can significantly enhance efficiency. However, one must consider factors like size, pressure rating, and material. These elements can complicate decisions, leading to regrets later.

Many users overlook specific details that might impact performance. Inadequate research can result in poor selections. Furthermore, understanding maintenance needs is often ignored. This oversight can lead to failures and added costs. Selecting the best motorized valve requires careful thought and attention to detail for optimal results.

Overview of Motorized Valves and Their Importance in Flow Control

Motorized valves play a vital role in flow control systems. They regulate the flow of liquids and gases with precision. These valves can be automated, making them essential in various industries. By using motorized valves, operators can achieve efficient and reliable control over processes.

Tips: Always check compatibility before installation. Not all valves work with every system. This could save time and prevent costly mistakes.

In applications ranging from HVAC to chemical processing, these valves enhance efficiency. They allow for quick adjustments in flow rates. However, selecting the right motorized valve isn’t always straightforward. Considerations include size, pressure ratings, and control methods. It can be daunting, and mistakes are common.

Tips: Regular maintenance is crucial. Accessing hard-to-reach valves can be a challenge. Keep spare parts readily available to minimize downtime.

The importance of motorized valves cannot be overstated. They improve safety and operational efficiency. Yet, it's essential to monitor performance regularly. Over time, wear and tear can lead to failures. Understanding the maintenance needs is key to sustainability.

Criteria for Selecting the Best Motorized Valves

When choosing motorized valves for efficient flow control, several criteria are essential. The valve's material influences its durability. Stainless steel is preferred for high corrosion resistance. According to a recent industry report, materials account for up to 25% of a valve's operational effectiveness in harsh environments.

Size and compatibility also matter. The wrong size can lead to inefficiency. Selecting a valve that matches your system's specifications will optimize performance. As the data shows, mismatched sizes can increase energy consumption by 20%. Look for adjustable options that accommodate variable flow rates.

Tips: Always analyze your system's requirements before purchasing. Consider the installation environment. If conditions are extreme, invest in higher-quality materials. A small initial oversight may lead to costly repairs later.

Actively monitor valve performance. A poorly functioning valve can disrupt entire systems. Implement regular maintenance checks. Reports indicate that neglecting this can reduce lifespan by 30%. Precision in selection and care is crucial for long-term efficiency.

Top 5 Best Motorized Valves for Efficient Flow Control

| Valve Type | Actuator Type | Flow Capacity (Cv) | Voltage (V) | Control Type |

|---|---|---|---|---|

| Ball Valve | Electric Actuator | 5.0 | 24 | On/Off |

| Butterfly Valve | Pneumatic Actuator | 10.0 | 120 | Modulating |

| Globe Valve | Electric Actuator | 3.5 | 240 | On/Off |

| Gate Valve | Hydraulic Actuator | 7.5 | 24 | On/Off |

| Check Valve | Electric Actuator | 4.0 | 120 | Reverse |

Top 5 Motorized Valves for Efficient Flow Control: Features and Benefits

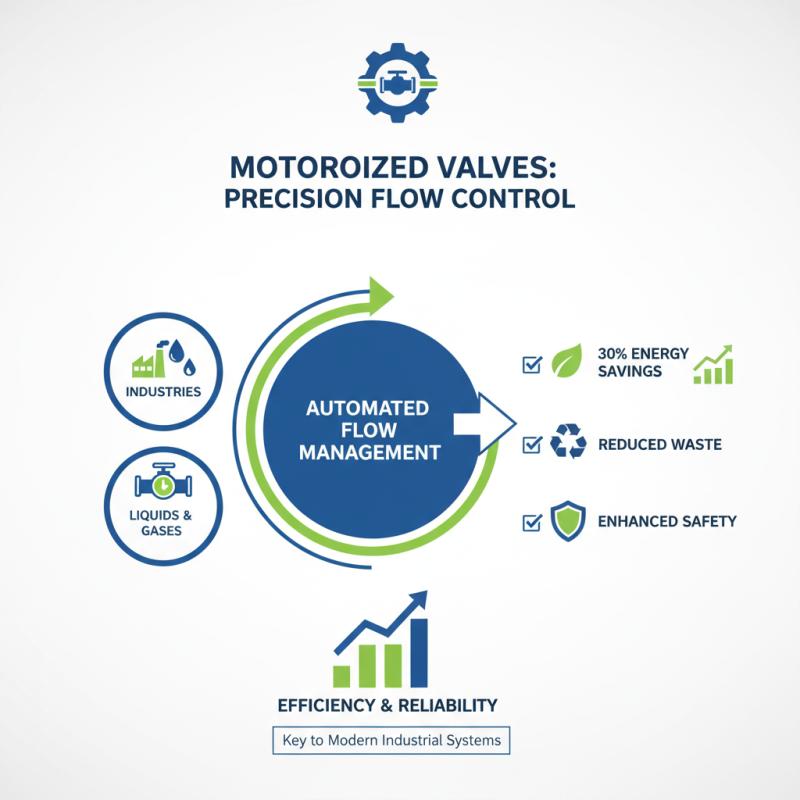

Motorized valves play a crucial role in flow control across various industries. They offer precise regulation of liquids and gases, ensuring efficiency and safety in operations. These valves can automate flow management, reduce energy consumption, and minimize waste. A recent industry report highlights that efficient flow control can lead to up to 30% energy savings in industrial systems.

When selecting a motorized valve, consider features like response time, power requirements, and material compatibility. The right valve enhances system performance and reliability. Reports indicate that motions with quick response times can significantly improve fluid dynamics. Furthermore, exploring valve materials is essential for maintaining longevity and preventing leaks or corrosion.

Tip: Check power consumption ratings when choosing a motorized valve. It can impact your operational costs.

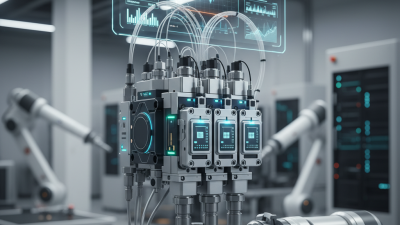

Another valuable aspect is the adaptability of motorized valves. They can be integrated with IoT systems for remote monitoring. However, many installations face challenges with compatibility, leading to inefficiencies.

Tip: Make sure your control system supports the valve's specifications.

Ultimately, the choice of a motorized valve is critical. Analyze your specific needs to avoid potential errors in implementation. Efficient flow control can significantly improve productivity when you select the right valve technology.

Comparison of Performance and Durability Among Leading Motorized Valves

When evaluating motorized valves, performance and durability are crucial factors. A recent industry report highlights that efficient flow control can increase system performance by up to 25%. However, not all motorized valves meet these standards. The longevity of a valve significantly affects operational costs.

Valves that fail within a few years lead to more replacements and downtime.

Material choice is essential. Brass and stainless steel offer durability but vary in performance under pressure. A study found that valves made from high-quality materials last 30% longer than their cheaper counterparts. Also, valve design impacts efficiency. Compact designs often reduce flow resistance, which is key for optimal performance.

Tips: Regular maintenance checks can prevent premature failure. Inspect seals and electrical connections. Consider the installation environment. Dust and moisture can cause issues over time. Investing in higher quality valves may reduce long-term costs. Remember, the initial price does not always reflect performance capability. Inconsistencies in product specifications require careful evaluation.

Balancing cost and quality is challenging. Not all reputable brands deliver consistent durability, adding to buyer’s anxiety. Users must often revisit their choices to ensure they achieve maximum efficiency from their systems.

Maintenance and Installation Tips for Optimal Valve Performance

When installing motorized valves, proper placement is crucial. Ensure the valve is easily accessible for future maintenance. Avoid cramped spaces.

Check the alignment carefully; any misalignment can cause future issues. Take your time during installation.

Regular maintenance is key to optimal performance. Inspect seals and gaskets for wear. Replace them as needed. Listen for unusual noises during operation. This can indicate a problem. A valve that sticks or doesn’t respond properly may need adjustment. Keep an eye on fluid leaks. They can lead to bigger issues if not addressed promptly.

Cleaning is also essential. Dust and debris can impact valve functionality. Use a soft cloth to wipe surfaces. Avoid harsh chemicals that could damage components. Don’t wait too long between checks. A proactive approach can save time and money. It’s about finding balance. Sometimes, things might go wrong. Reflect on past installations to improve future performance.

Related Posts

-

Exploring the Future of Pneumatic Control Valves in 2025 Top Digital Innovations

-

2025 Top 5 Motorized Valves: Best Picks for Efficiency and Performance

-

10 Essential Tips for Choosing the Right Basket Strainers in Your Projects

-

How to Choose the Right Pneumatic Actuator for Your Application in 2025

-

Exploring Duplex Strainer Innovations at the 138th Canton Fair in 2025

-

Understanding the Benefits of Basket Strainers in Industrial Applications