Blog

Best Pneumatic Flow Control Valve Options for Efficient Fluid Management

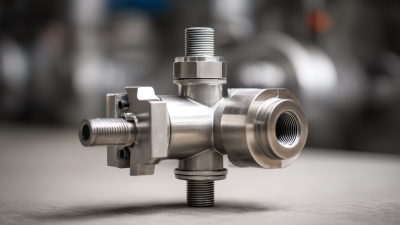

In the realm of fluid management, the efficiency and precision of pneumatic systems play a crucial role in industrial applications. One of the key components that facilitate optimal fluid control is the pneumatic flow control valve. These valves are designed to regulate the flow rate of gases within a system, ensuring that processes run smoothly and reliably. With a variety of options available, selecting the right pneumatic flow control valve can significantly enhance operational efficiency and reduce downtime in various applications.

Understanding the features and functions of different pneumatic flow control valves is essential for engineers and decision-makers tasked with developing efficient fluid management systems. Factors such as valve design, size, material compatibility, and response time can influence the overall performance of these components. By carefully evaluating the available options and aligning them with specific operational requirements, organizations can attain improved control over fluid dynamics, ultimately leading to enhanced productivity and system longevity.

As industries continue to evolve, the demand for innovative solutions that offer flexibility and efficiency in fluid management remains high. This highlights the importance of selecting the best pneumatic flow control valve options that not only meet current needs but also pave the way for future advancements in technology and process optimization.

Overview of Pneumatic Flow Control Valves and Their Applications

Pneumatic flow control valves play a crucial role in managing the flow of air and other gases in various industrial applications. These valves regulate the speed and direction of airflow, ensuring that systems operate efficiently and effectively. Commonly used in automation, manufacturing, and processing industries, pneumatic flow control valves help optimize equipment performance, improve safety, and enhance productivity. Their applications range from controlling actuators in robotics to managing pneumatic tools and equipment in assembly lines.

When selecting a pneumatic flow control valve, it’s important to consider factors such as flow rate, pressure range, and response time. A well-chosen valve can significantly impact system performance, achieving smoother operation and better control over fluid dynamics. Additionally, proper installation and maintenance are essential for ensuring longevity and reliability.

Tips: Always consult with your engineering team to identify specific process requirements before choosing a valve. Regular maintenance checks can prevent unexpected downtimes, so schedule routine inspections to keep your pneumatic systems running smoothly. Lastly, understanding the environmental conditions in which the valve will operate can guide you in selecting materials that resist corrosion and wear.

Key Factors to Consider When Selecting a Pneumatic Flow Control Valve

When selecting a pneumatic flow control valve, several key factors should be considered to ensure optimal performance and efficiency in fluid management. First, it's essential to understand the pressure and flow requirements of your specific application. Knowing the maximum pressure and flow rate will help you choose a valve that can handle the demands without compromising functionality. Additionally, consider the valve's response time, as a quicker response can significantly enhance control precision in dynamic systems.

Another factor to consider is the material and construction of the valve. Different environments—such as high temperatures or corrosive substances—require valves made from specific materials to ensure durability and longevity. Selecting the right material not only affects performance but also maintenance requirements and overall system reliability.

Tip: Always consult technical specifications and product datasheets to make informed decisions about materials and compatibility. Moreover, ensure that the installation setup is suitable for the selected valve, as improper installation can lead to leaks and system inefficiencies.

Tip: Prioritize valves with adjustable flow settings for greater flexibility in your operations. This enables fine-tuning of fluid flow based on real-time demands, enhancing operational efficiency and overall resource management.

Best Pneumatic Flow Control Valve Options for Efficient Fluid Management

This chart displays the flow rate of various pneumatic flow control valves, which is a crucial factor for efficient fluid management. When selecting a valve, consider the flow rate along with other factors such as pressure, material compatibility, and response time.

Top Pneumatic Flow Control Valve Options for Various Industry Needs

When selecting pneumatic flow control valves, it’s essential to consider the specific requirements of various industries. Different applications demand unique features and functionalities in flow control, making it crucial to align valve characteristics with operational needs. For instance, in manufacturing settings where precision is paramount, valves that offer fine-tuning capabilities are preferred. These valves allow operators to adjust the flow rates with high accuracy, ensuring that processes run smoothly and efficiently.

In the field of automation, reliability and responsiveness are key. Pneumatic flow control valves designed for fast-acting applications can greatly enhance the performance of automated systems. These valves are engineered to provide quick response times, minimizing delays in the handling of fluids. Meanwhile, industries such as food and beverage or pharmaceuticals may prioritize valves that are easy to clean and maintain, ensuring compliance with health and safety standards. Selecting the right type of pneumatic flow control valve not only optimizes fluid management but also contributes to overall process efficiency and reliability in meeting industry-specific regulations.

Maintenance and Troubleshooting Tips for Pneumatic Flow Control Valves

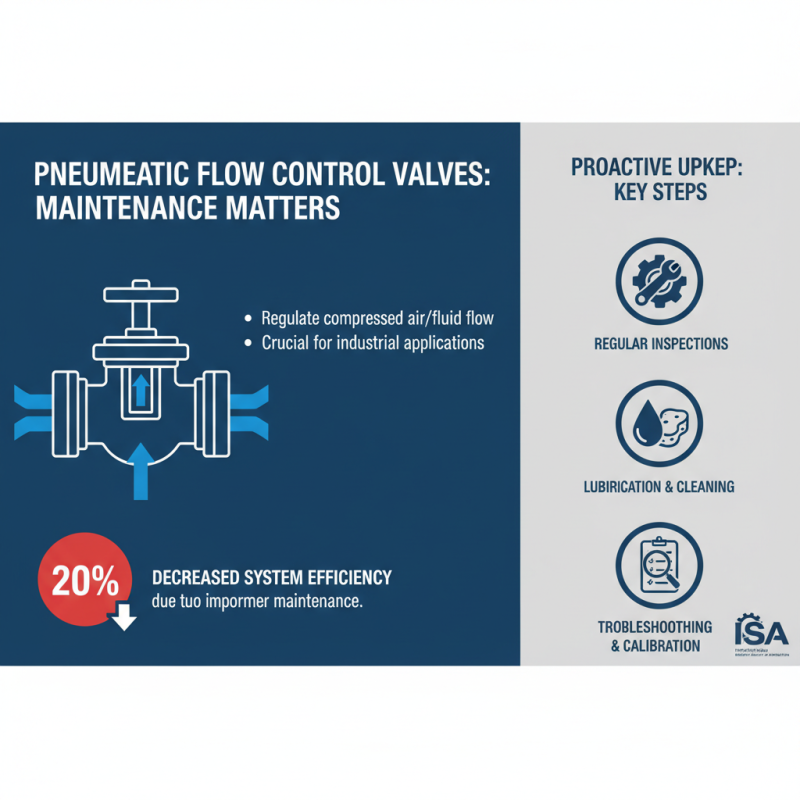

Pneumatic flow control valves play a crucial role in regulating the flow of compressed air and fluids in various industrial applications. To ensure these valves operate effectively, regular maintenance and troubleshooting are essential. According to a report by the International Society of Automation, improper valve maintenance can lead to a 20% decrease in system efficiency, emphasizing the importance of a proactive approach to upkeep.

One of the essential tips for maintaining pneumatic flow control valves is to regularly inspect the seals and diaphragm for signs of wear or damage. Rubber seals and diaphragms, when compromised, can lead to leaks and inefficient operation. A simple visual check can help identify these issues before they escalate. Furthermore, keeping the surrounding area clean and free of debris will contribute to the longevity of the valve and prevent contamination.

In terms of troubleshooting, it's vital to monitor the valve's response to control signals. A sluggish response can indicate issues like air supply problems or internal blockages. Utilizing pressure gauges and flow meters can aid in diagnosing these problems effectively. By addressing these common issues promptly, facilities can avoid costly downtime and ensure their pneumatic systems run at peak performance. Regularly updating maintenance schedules based on usage data can help predict wear and maintain operational efficiency.

Advantages of Using Pneumatic Flow Control Valves in Fluid Management

Pneumatic flow control valves play a crucial role in efficient fluid management by regulating the flow of air and liquids in various industrial applications. These valves work by utilizing the principles of pneumatics to maintain a controlled flow rate, which optimizes system performance and enhances safety. One of the primary advantages of using pneumatic flow control valves is their ability to respond quickly to changing conditions, enabling precise adjustments that can improve overall operational efficiency. This responsiveness helps in minimizing energy consumption, reducing wear and tear on equipment, and ultimately leading to cost savings in the long run.

When selecting the right pneumatic flow control valve, consider the specific requirements of your system. Ensure that the valve can handle the desired flow rates and pressures for your application. Tips such as evaluating the material compatibility with the fluids being managed and assessing the required temperature range can also aid in making an informed choice. Additionally, regular maintenance and proper installation of these valves will significantly enhance their performance and longevity, ensuring your fluid management system operates at peak efficiency.

Utilizing pneumatic flow control valves can also lead to improved automation capabilities within fluid management systems. By integrating these valves with sensors and control systems, operators can achieve better monitoring and control of fluid dynamics in real time. This level of automation not only enhances operational efficiency but also contributes to safer working environments by minimizing human intervention in potentially hazardous processes.

Related Posts

-

Why Understanding Pneumatic Flow Control Valves is Essential for Efficient Industrial Processes

-

Exploring the Future of Pneumatic Control Valves in 2025 Top Digital Innovations

-

Top 5 Pneumatic Valves to Watch in 2025: Features and Applications

-

Understanding the Benefits of Butterfly Valves in Modern Industrial Applications

-

10 Essential Tips for Choosing the Right Check Valves for Your Projects

-

How to Choose the Right Pneumatic Butterfly Valve for Your Applications