Blog

Understanding Different Butterfly Valve Types and Their Applications

Butterfly valves are a crucial component in various industrial applications, providing efficient control over fluid flow with their unique design and functionality. Understanding the different butterfly valve types is essential for selecting the appropriate valve for a specific application, as each type comes with its own set of characteristics and advantages. From resilient seated valves that offer versatility and cost-effectiveness to high-performance variants designed for more demanding conditions, the diversity in butterfly valve types cater to a wide range of operational needs.

As industries evolve, the role of butterfly valves in fluid management continues to expand, necessitating a comprehensive understanding of their applications across sectors such as water treatment, oil and gas, and HVAC systems. Each butterfly valve type has distinct features tailored to optimize performance under various pressures, temperatures, and flow rates. This article will explore the classifications of butterfly valves, their operational mechanisms, and the specific scenarios in which they excel, providing a valuable resource for engineers and decision-makers in selecting the right valve for their applications. By gaining insight into butterfly valve types, one can better appreciate their impact on efficiency and reliability in fluid control systems.

Types of Butterfly Valves: A Comprehensive Overview

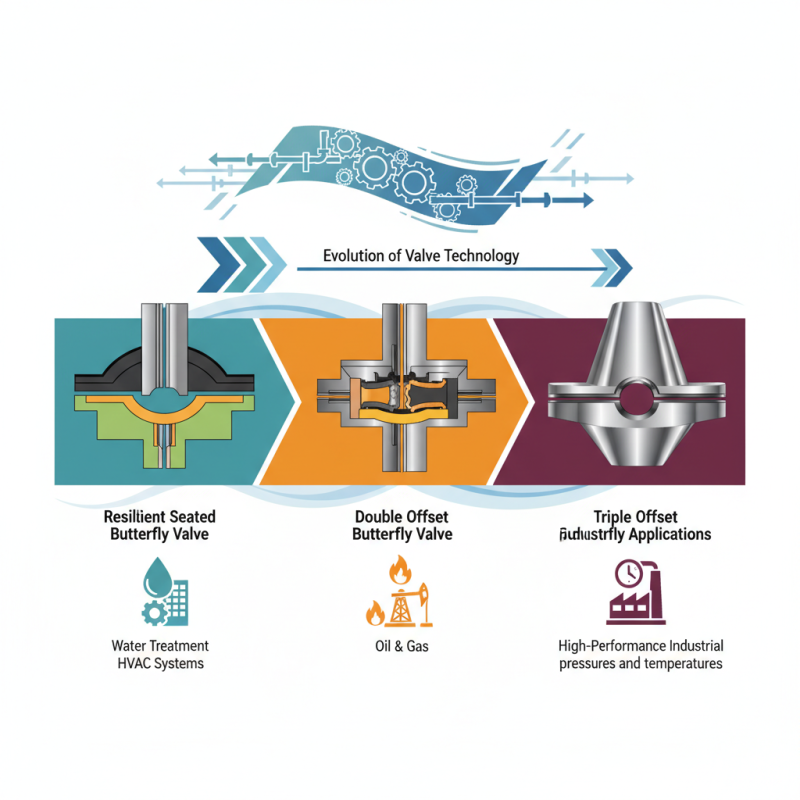

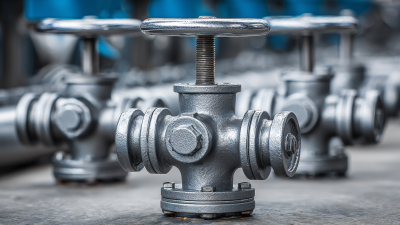

Butterfly valves are essential components in various industrial applications, known for their simple yet effective design. They are primarily categorized into several types based on their operating mechanisms, materials, and specific use cases. The most common types include resilient seated, high-performance, and triple-offset butterfly valves. Resilient seated valves are often used for on-off applications in water systems, providing a reliable seal when closed. High-performance butterfly valves, designed for higher pressure and temperature conditions, find applications in chemical processing and power generation due to their robust construction and ability to handle various media.

Another significant type is the triple-offset butterfly valve, which features a unique design that allows for better sealing and minimal wear over time. This type is ideal for industries dealing with high-pressure and high-temperature fluids, such as oil and gas. Additionally, there are wafer-type and lug-type configurations that cater to different installation requirements and space constraints. Wafer-type valves are ideal for compact setups, while lug-type valves provide the benefit of disassembly without disrupting the pipeline.

Understanding the various types of butterfly valves and their applications is crucial for selecting the right one for a given industrial need, ensuring efficiency and reliability in fluid control systems.

Operating Mechanisms of Butterfly Valves: How They Function

Butterfly valves are essential components in various industrial applications, offering reliable control over fluid flow. Their operating mechanism is relatively straightforward, consisting of a disc that rotates around a central axis to either restrict or facilitate flow. When the valve is fully closed, the disc is positioned perpendicular to the flow direction, creating a tight seal. Conversely, when opened, the disc aligns parallel to the flow, allowing fluids to pass freely. The simplicity of this design contributes to its efficiency and effectiveness, particularly in large-diameter pipelines where pressure drops can be substantial, as noted in the Journal of Fluid Engineering.

According to a report by the Global Valve Market Research, the demand for butterfly valves is projected to grow at a compound annual growth rate (CAGR) of 4.5% from 2021 to 2028. This growth is attributed to their efficiency in handling both liquids and gases across various sectors such as water treatment and oil and gas. Furthermore, butterfly valves are favored for their lightweight and compact design, which allows for easy installation and maintenance. Their adaptability to various operating conditions, including high-pressure environments, underscores their utility. As industries continue to innovate and optimize fluid control systems, understanding the operating mechanisms of butterfly valves will be crucial for engineers and operators alike.

Applications of Butterfly Valves in Various Industries

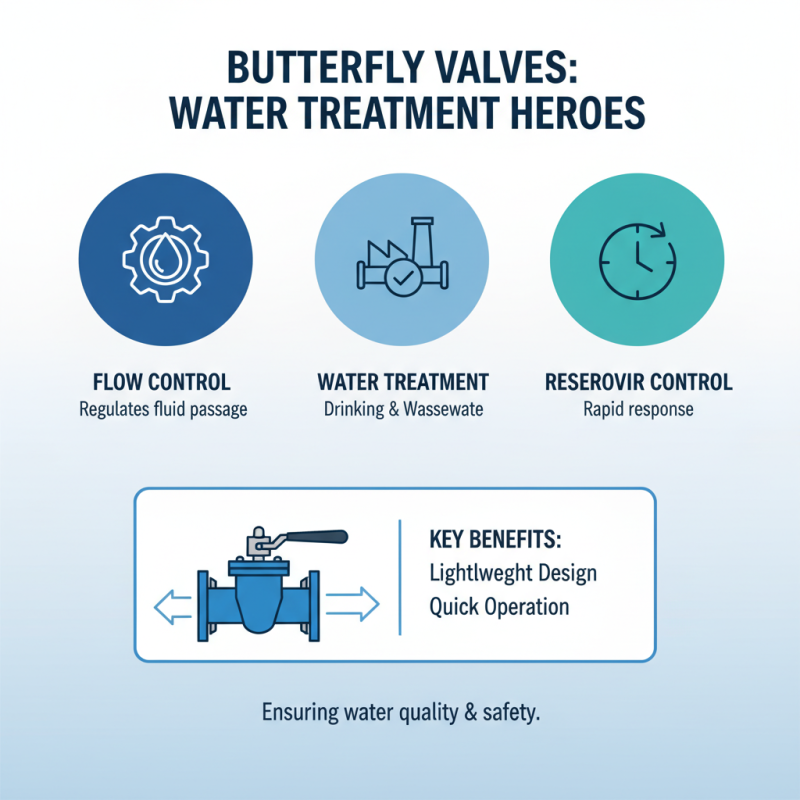

Butterfly valves are crucial components in various industries, serving as reliable flow control devices that regulate the passage of fluids. In the water treatment sector, these valves play a vital role in managing the flow of drinking water and wastewater. Their lightweight design and quick operation make them ideal for use in applications like reservoir control, where swift response times are essential for maintaining water quality and safety.

In the oil and gas industry, butterfly valves are often employed in pipelines to regulate the flow of liquids and gases. Their ability to provide a tight seal while minimizing pressure loss is particularly beneficial in high-volume applications. Additionally, the pharmaceutical and food processing industries rely on butterfly valves for their ease of cleaning and ability to maintain sanitary conditions. These industries require valves that can withstand rigorous cleaning practices while ensuring that no contamination occurs, making butterfly valves an excellent choice for ensuring compliance with stringent health and safety standards.

Benefits and Limitations of Different Butterfly Valve Types

Butterfly valves are widely used in various industrial applications, and each type offers unique benefits and limitations. The most common types include resilient seated, high-performance, and triple offset butterfly valves. Resilient seated butterfly valves are known for their cost-effectiveness and ease of maintenance. They provide a reliable sealing capability, making them suitable for on-off applications in water and wastewater treatment. However, their performance can be limited under high-temperature and high-pressure conditions, which restricts their use in more demanding settings.

High-performance butterfly valves are designed for more rigorous applications, delivering reliable performance under a wider range of conditions. They offer superior flow control and sealing capabilities, making them ideal for systems involving gases and liquids with varying pressure levels. Nonetheless, these valves can come at a higher upfront cost and may require more complex installation processes, which could affect overall project timelines.

Triple offset butterfly valves provide exceptional sealing and durability, particularly in high-pressure environments. Their design minimizes wear and tear, making them suitable for critical applications in sectors such as oil and gas. However, the complexity of their design can lead to more expensive maintenance and longer lead times for repair or replacement. Understanding these benefits and limitations is essential for selecting the appropriate valve type for specific applications, ensuring optimal performance and reliability in any system.

Understanding Different Butterfly Valve Types and Their Applications

Selection Criteria for Choosing the Right Butterfly Valve

When selecting the appropriate butterfly valve for a specific application, several critical criteria should be taken into account to ensure optimal performance and longevity. First and foremost, the size and type of the piping system are crucial. The valve must fit seamlessly within the existing infrastructure, so measuring the diameter and understanding the flow requirements are essential steps in the selection process.

Additionally, the operating conditions, including temperature, pressure, and the type of media being controlled, will significantly influence the choice of valve. For instance, high-temperature applications may necessitate valves made from materials that can withstand extreme heat, while corrosive environments may require specialized coatings or materials to prevent deterioration.

Tips: Always consult with an expert in fluid mechanics to understand the specific needs of your system better. Moreover, consider the maintenance requirements of the valve types you are evaluating. Opting for valves that are easier to service can save costs and minimize downtime in the long run. Understanding these factors not only improves the efficiency of your system but also enhances the reliability of operations.

Related Posts

-

Top 5 Types of Butterfly Valves You Need to Know for Optimal Performance

-

2025 Top 5 Pneumatic Control Valves for Optimal Industrial Automation

-

Top 10 Globe Valves Types and Their Applications in Industrial Systems You Should Know

-

How to Choose the Right Basket Strainers for Your Industrial Needs

-

Exploring Pneumatic Rotary Actuator Innovations at 2025 China Import and Export Fair

-

Revolutionizing Industrial Automation with Cutting-Edge Pneumatic Valve Actuators