Blog

2026 How to Choose the Best Pneumatic Rotary Actuator for Your Needs?

Choosing the right pneumatic rotary actuator is essential for various applications. Whether in manufacturing or automation, it impacts performance and efficiency. These devices convert air pressure into rotational motion, making them vital for many systems.

When selecting a pneumatic rotary actuator, consider several factors. The load requirements, speed, and range of motion are critical. It's not just about the specifications. You must also evaluate the environment where the actuator will operate. For instance, harsh conditions can affect performance.

Costs and maintenance are often overlooked but crucial. A suitable actuator may require more investment up front. Yet, long-term efficiency and durability can save money. A hasty choice may lead to unexpected issues. Reflecting on your specific needs ensures a better fit for your operation.

Understanding Pneumatic Rotary Actuators and Their Applications

Pneumatic rotary actuators play a crucial role in various industrial applications. They convert compressed air into mechanical motion, providing precise control. According to industry reports, pneumatic actuators account for about 30% of the actuator market globally. This reflects their popularity due to efficiency and reliability.

These actuators are commonly used in manufacturing, robotics, and process industries. They excel in environments where speed and torque are essential. Applications range from simple open-and-close operations to complex movements in assembly lines. The versatility makes them suitable for heavy-duty tasks. However, one must consider their limitations. Factors like ambient temperature and air quality can affect performance.

While pneumatic rotary actuators offer numerous advantages, not every solution fits all needs. The selection process can be challenging. It’s crucial to analyze operational requirements carefully. High pressure doesn't always mean better performance. Users may overlook installation space or maintenance needs, leading to operational inefficiencies.

2026 How to Choose the Best Pneumatic Rotary Actuator for Your Needs?

| Dimension | Value | Application | Remarks |

|---|---|---|---|

| Torque Output | 50-100 Nm | Packaging Industry | Suitable for light applications |

| Operating Pressure | 4-8 bar | Food Processing | Compliance with hygiene standards |

| Rotation Angle | 90° to 270° | Robotics | Versatile positioning |

| Body Material | Aluminum Alloy | Automotive | Lightweight and durable |

| Weight | 2.5 kg | Material Handling | Easy installation |

Key Factors to Consider When Selecting a Pneumatic Rotary Actuator

Choosing the right pneumatic rotary actuator can significantly impact your operations. When selecting one, consider key factors such as the torque requirement, rotation angle, and environmental conditions. Torque is crucial; a study shows that 70% of performance issues stem from incorrect torque ratings. Understand your application needs thoroughly to avoid mismatched specifications.

Don't forget to factor in the rotation angle. Most actuators vary, with some providing a full 360-degree rotation, while others are limited. The environment plays a role, too. If the actuator will be in a dusty or wet area, ensure it has adequate protection. According to industry standards, 45% of actuator failures are due to inadequate environmental considerations.

Comparing Different Types of Pneumatic Rotary Actuators Available

When exploring pneumatic rotary actuators, it’s vital to understand the different types available. These devices come in various forms, each suited for specific applications. Common types include rack and pinion actuators, vane actuators, and scotch-yoke actuators. Each has unique characteristics, and recognizing these can help you make an informed choice.

Rack and pinion actuators are known for their high torque output. They are reliable and often used in tasks requiring precise control. Alternatively, vane actuators have fewer moving parts, leading to less maintenance. However, their performance might not match that of rack and pinion types under heavy loads. Scotch-yoke actuators excel in high-speed applications but may suffer from wear over time.

Tips: Carefully assess your application needs. Evaluate the environment where the actuator will operate. Consider factors such as temperature, humidity, and potential exposure to chemicals. Always account for the load requirements. Going too light may lead to malfunctions, while overly heavy choices can waste energy. It’s crucial to strike that balance.

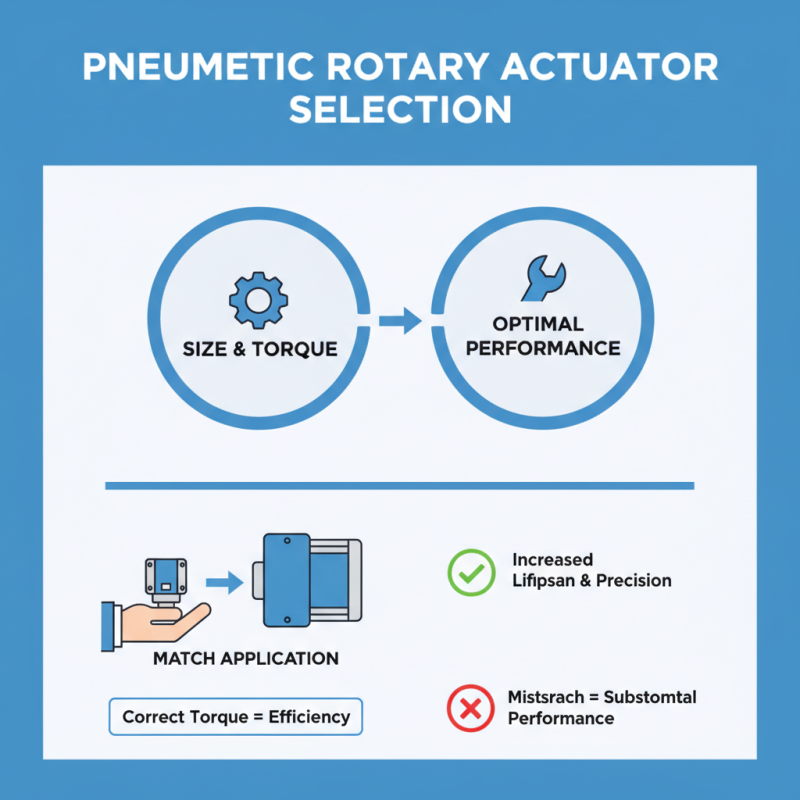

Determining the Size and Torque Requirements for Your Application

When choosing a pneumatic rotary actuator, size and torque are crucial. The size of the actuator affects its fit within the system. Consider the available space. It must be compact enough yet powerful. Measure the area where it will be installed. Accurate measurements are essential.

Torque requirements are another key factor. Assess the load the actuator will handle. A mismatch can lead to failures. Too little torque results in insufficient motion. Too much can cause wear. It's vital to calculate the exact torque needed based on application specifics.

**Tips:** Focus on the weight of the items moved. Test in real-world scenarios. Sometimes, overestimating torque can lead to unnecessary costs. Look at similar applications for guidance. Understanding the dynamics can refine your choice. Be sure to document your findings as you experiment with different configurations.

Torque Requirements for Pneumatic Rotary Actuators

Essential Features to Look for in a Quality Pneumatic Rotary Actuator

When selecting a pneumatic rotary actuator, several essential features demand attention. Start with size and torque. Industry reports suggest that the proper torque rating can determine your actuator's efficiency. For example, actuators must match the specific application to work effectively. A mismatch can lead to suboptimal performance.

Next, consider the build quality. Materials matter. Corrosion-resistant components can drastically enhance reliability. A study by the International Society of Automation indicated that high-quality materials could reduce maintenance costs by up to 30%. Be mindful of the actuator’s weight and mounting style too. Weights that are too heavy might complicate installation.

Another crucial factor is response time. Faster actuators reduce wait times in highly automated systems. Timing is everything. A delay of just a second can impact productivity. It’s also vital to reflect on the actuator’s environment. Extreme temperatures or humidity levels can affect performance. Choose an actuator that meets your specific operational conditions to avoid failure.

Related Posts

-

Why Pneumatic Rotary Actuators Are Essential for Modern Automation

-

Exploring Pneumatic Rotary Actuator Innovations at 2025 China Import and Export Fair

-

How to Choose the Right Pneumatic Actuator for Your Application in 2025

-

Best Pneumatic Flow Control Valve Options for Efficient Fluid Management

-

Understanding Hydraulic Actuators: How They Improve Efficiency in Industrial Automation by 30%

-

Top Motorized Valves for 2025 Which One is Right for Your Needs