Blog

Why Choose a Hydraulic Actuator for Your Automation Needs?

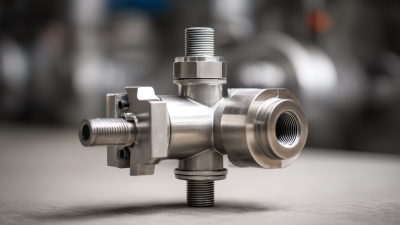

In today's fast-paced industrial landscape, choosing the right actuator is crucial. A hydraulic actuator stands out among various options available. This device uses fluid power to create motion, making it suitable for heavy-duty applications. Hydraulic actuators offer remarkable force generation and precise control.

Industries are increasingly turning to hydraulic solutions. They provide efficiency and reliability that electric alternatives often cannot match. With varying sizes and designs, hydraulic actuators can fit numerous applications. Their ability to handle extreme loads makes them indispensable in sectors like manufacturing and construction.

However, it’s essential to note some challenges. Hydraulic systems require regular maintenance to ensure optimal performance. Leaks may occur, which can compromise efficiency. Assessing these potential downsides is crucial. Making an informed decision on using hydraulic actuators enhances overall automation in any project.

Overview of Hydraulic Actuators in Automation Systems

Hydraulic actuators play a crucial role in modern automation systems. Their ability to provide high force output and precise control sets them apart. According to market research, the hydraulic actuator market is expected to reach $14 billion by 2025. This growth highlights their importance in various applications, including manufacturing and robotics.

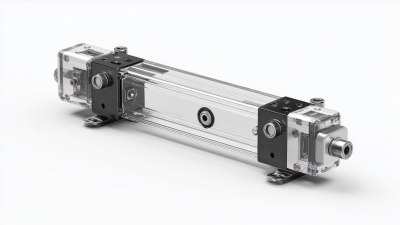

These actuators operate by using pressurized hydraulic fluid for movement. They offer advantages like high torque and fast response times. For example, they can achieve speeds up to 200 in/s, making them ideal for tasks requiring quick adjustments. However, maintenance is essential. Hydraulic systems can leak and lose efficiency over time, leading to performance issues.

While hydraulic actuators have many benefits, there are challenges to consider. The initial setup cost can be higher than electric alternatives. Furthermore, they require a reliable source of hydraulic fluid, which can complicate installation. With innovations in technology, many manufacturers are exploring better designs to overcome these hurdles. Despite these imperfections, the versatility of hydraulic actuators remains an attractive option for many automation needs.

Advantages of Hydraulic Actuators Compared to Other Actuators

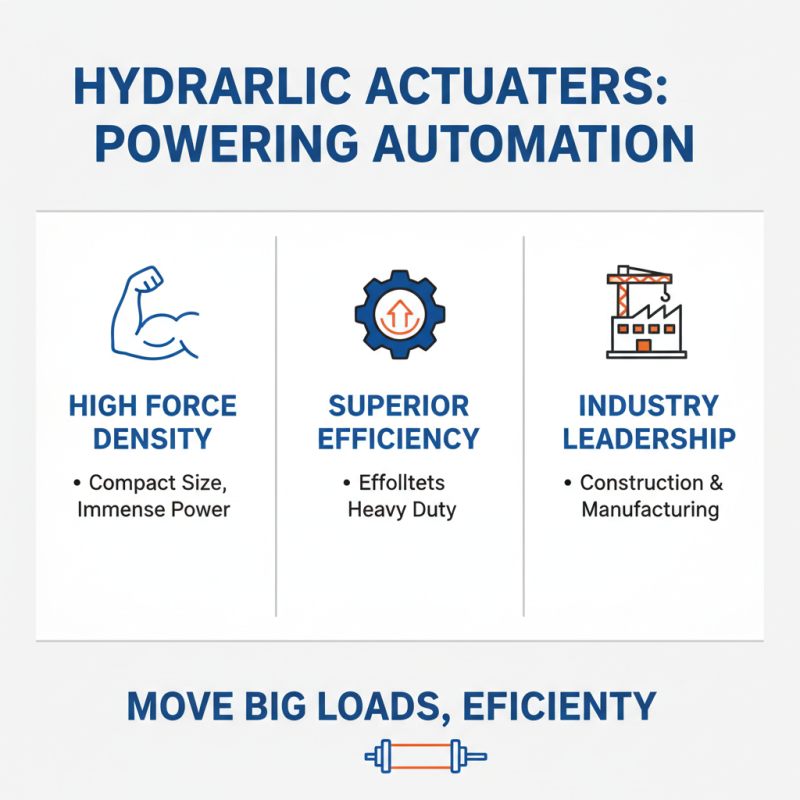

Hydraulic actuators stand out in automation due to their power and efficiency. They provide high force in a compact size, which many electric actuators cannot match. These actuators excel in heavy-duty applications, capable of moving large loads with ease. This capability is particularly important in industries like construction and manufacturing.

One key advantage of hydraulic actuators is their speed. They can operate faster than many alternatives. However, users should consider their maintenance needs. Hydraulic systems often require regular checks for leaks and fluid quality. This can be a downside for some operations. Nevertheless, when properly maintained, hydraulic actuators can deliver consistent, reliable performance.

Flexibility is another strong point. These actuators can be used in various environments. Temperature fluctuations and harsh conditions won’t significantly affect them. Yet, it's vital to evaluate your specific requirements. Not every situation calls for hydraulic power. Weighing the pros and cons will lead to better decisions in choosing the right actuator for your automation needs.

Key Applications of Hydraulic Actuators in Various Industries

Hydraulic actuators play a vital role in several industries due to their powerful and precise movement capabilities. In manufacturing, these actuators can quickly lift heavy materials. They reduce human effort and increase efficiency. Many factories utilize hydraulic systems in assembly lines. This technology helps automate processes, leading to higher productivity.

In the construction sector, hydraulic actuators operate machinery like excavators and cranes. These machines require significant force to lift and move loads. However, their reliance on hydraulic systems can lead to maintenance challenges. Regular checks are essential to prevent breakdowns. Operators must carefully monitor these systems for leaks or pressure drops.

The aerospace industry also employs hydraulic actuators for controlling flight surfaces. The precision they provide is critical for safety. Yet, maintaining these systems is complex and requires trained personnel. Mishaps can occur if not properly managed. Hydraulic systems, while beneficial, pose risks that need attention and proper management.

Factors to Consider When Choosing Hydraulic Actuators

When selecting hydraulic actuators for automation, various factors come into play. Consider the application requirements first. The load capacity must match the task. A small actuator might not handle larger loads efficiently. Yet, oversized actuators can lead to wasted energy. Pay attention to the speed requirements, too. Some projects require quick responses, while others can work at slower rates.

Another important aspect is the operating environment. Hydraulic actuators often face dust, dirt, or moisture. Make sure they are suited for harsh conditions. This helps avoid premature failures. Additionally, think about maintenance needs. Some systems may require frequent checks, while others have self-lubricating components. Complexity can affect overall reliability.

Cost is a common concern as well. While high-quality actuators may demand a higher investment, they often offer longer service life. Balancing quality with budget constraints can be challenging. Don't forget to evaluate energy efficiency, too. Hydraulic systems should be efficient to minimize operational costs. Ensuring you consider these various elements can lead to better choices for your automation needs.

Maintenance and Care for Optimal Hydraulic Actuator Performance

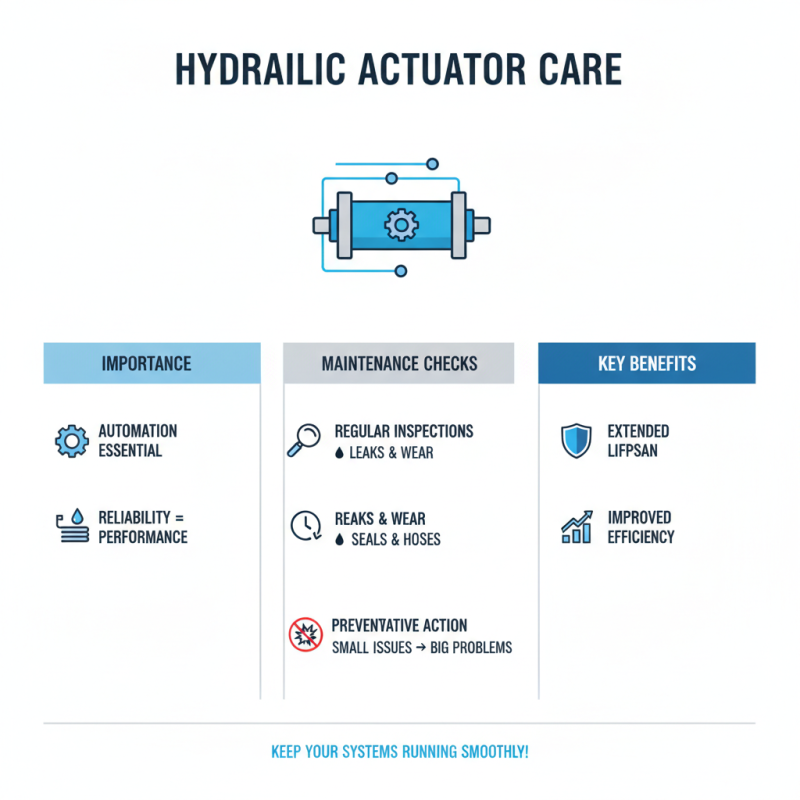

Hydraulic actuators are essential in many automation processes. However, their performance significantly relies on proper maintenance and care. Regular inspections help identify leaks and wear. It's vital to check seals and hoses often. Small issues can escalate quickly if neglected.

Fluid quality is another critical factor. Contaminated fluid can damage internal components. Use filters to keep the hydraulic fluid clean. Regularly change the fluid according to the manufacturer's recommendations. This simple action can prevent costly breakdowns.

Temperature control also plays a crucial role. High temperatures can lead to reduced efficiency and premature failure. Ensure that cooling systems operate correctly. Overheating can warp components, leading to performance issues. Be vigilant about monitoring operating conditions, and address any anomalies immediately.

Related Posts

-

Understanding Hydraulic Actuators: How They Improve Efficiency in Industrial Automation by 30%

-

2026 Best Hydraulic Actuator Types for Your Project Needs?

-

2026 Top Hydraulic Actuator Types for Your Applications?

-

Top 10 Hydraulic Actuators: Boost Your Machinery Efficiency Today

-

Why Understanding Pneumatic Flow Control Valves is Essential for Efficient Industrial Processes

-

Unlocking Automation: The Future of Electric Actuators in Smart Technology