Blog

Why Choose a Hydraulic Rotary Actuator for Your Next Project?

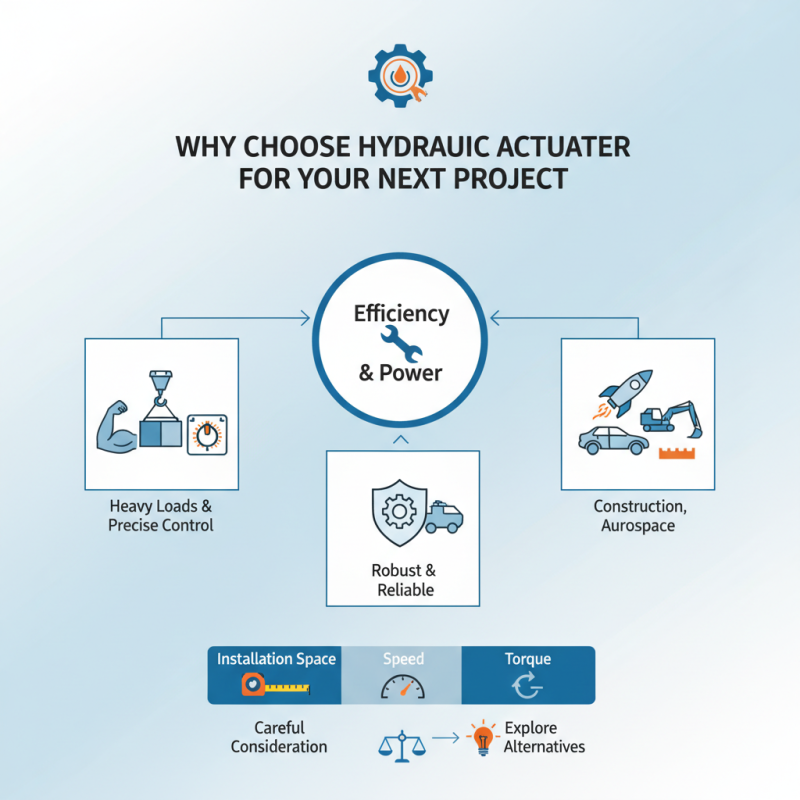

In many engineering applications, a hydraulic rotary actuator stands out for its efficiency and power. It converts hydraulic pressure into rotational movement, making it ideal for various tasks. Whether in construction, automotive, or aerospace, this type of actuator is robust and reliable.

When considering a hydraulic rotary actuator for your next project, the benefits are clear. Its ability to handle heavy loads and provide precise control is unmatched. You may also find that these actuators are more durable than other options available. Projects often demand reliability, and hydraulic rotary actuators deliver.

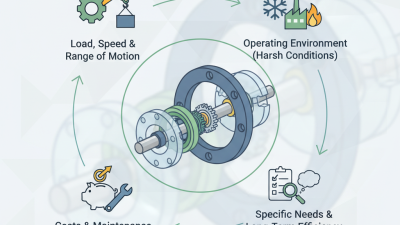

However, choosing the right actuator requires careful thought. Factors such as installation space, speed, and torque need to be considered. Not every project fits the hydraulic rotary actuator mold. Exploring alternatives can lead to insights. Reassessing your project's unique requirements is important for optimal results.

Benefits of Hydraulic Rotary Actuators in Industrial Applications

Hydraulic rotary actuators are increasingly popular in industrial applications.

They offer a range of advantages that can boost project efficiency.

These actuators convert hydraulic energy into rotational motion. This process allows for precise control and high torque.

In situations where heavy loads are handled, hydraulic systems stand out.

They provide superior strength compared to electric options.

One key benefit is their ability to operate in harsh environments.

Extreme temperatures, dust, and moisture do not impair their functionality. This durability makes them suitable for a variety of industries.

Consider a manufacturing line; an actuator might rotate heavy equipment with ease.

However, installation can be complex, and maintenance is crucial for long-term reliability.

Another aspect to reflect on is energy efficiency.

Hydraulic rotary actuators consume energy based on the load they carry. This means they can save resources compared to constant power supply systems.

Still, the complexity of hydraulic lines and potential leaks can create challenges. Engineers must carefully design these systems to avoid waste.

Despite these hurdles, the benefits often outweigh the drawbacks when applied correctly.

Key Technical Specifications of Hydraulic Rotary Actuators to Consider

Hydraulic rotary actuators are vital for various applications. When choosing one, consider key technical specifications. Pay attention to torque output and operating pressure. These elements directly influence performance. Always check the actuator’s speed and efficiency. A well-balanced actuator will operate smoothly.

Tips: Evaluate the installation space. Ensure you have enough room for maintenance. Compact designs can help in tight spots.

Look at the materials used in construction. Corrosion-resistant materials are better for harsh environments. Also, consider temperature ranges. High or low temperatures can affect functionality.

Noise levels should not be overlooked. Some actuators operate quietly, while others can be quite loud. Keep this in mind based on your application. Finally, consult with engineers to understand your project’s needs thoroughly.

Comparative Analysis: Hydraulic vs. Electric Rotary Actuators

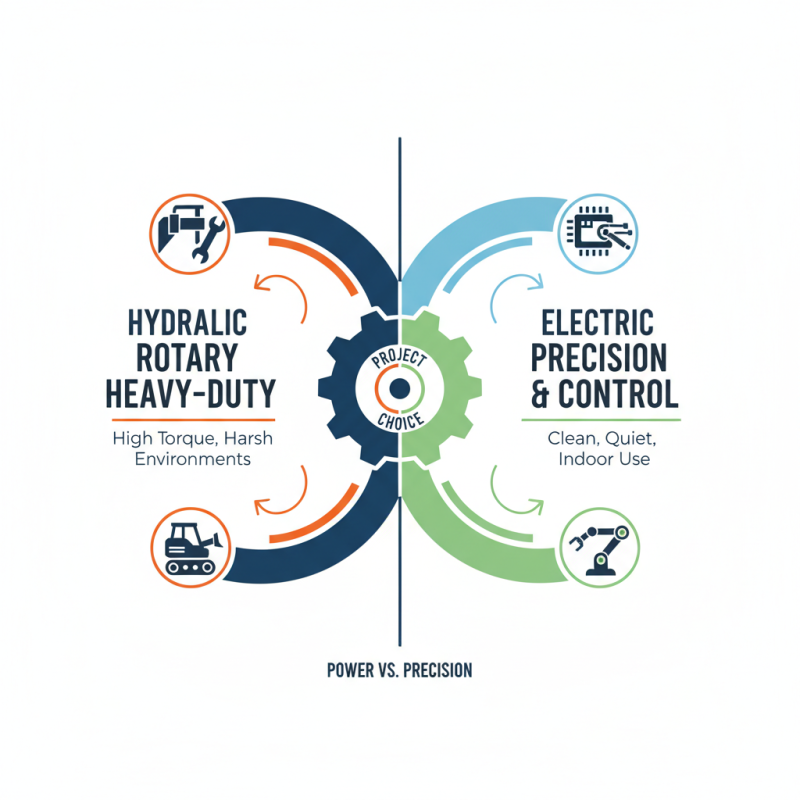

When planning your next project, the choice between hydraulic and electric rotary actuators can be challenging. Hydraulic rotary actuators excel in heavy-duty applications. They provide high torque and can operate effectively in harsh environments. In contrast, electric actuators are often favored for their precision and ease of control. They are cleaner and quieter, making them suitable for indoor environments.

However, hydraulic systems often require more maintenance. Leakage can occur, leading to potential downtime. They may also consume more energy, especially in smaller applications where efficiency is crucial. Electric actuators don’t have these issues, but they may struggle with high load capacities. They can overheat if used continuously under heavy loads.

Project requirements vary widely, making one option not inherently better than the other. Hydraulic actuators might be overkill for lighter tasks. Similarly, electric actuators might fall short for high-demand applications. Understanding the specific needs of your project is vital. Weigh the pros and cons carefully to make an informed decision.

Industry Standards and Regulations Impacting Hydraulic Actuator Use

Hydraulic actuators are vital in various industries, ensuring compliance with stringent industry standards. These standards often stem from organizations like ISO and ANSI. According to a recent report from the International Organization for Standardization, hydraulic actuators must meet specific pressure and temperature regulations to guarantee safety and efficiency.

One key regulation impacts the design and manufacturing of hydraulic actuators. It often requires testing under extreme conditions. Actuators must handle diverse environments, sometimes with varying fluid properties. This can lead to performance inconsistencies, making adherence to these standards challenging. A study found that about 30% of actuators fail during regular inspections due to non-compliance with these guidelines.

Aside from regulatory standards, environmental considerations also play a role. Companies must consider emissions and energy efficiency. For example, the EU's Ecodesign directive mandates that hydraulic systems must minimize energy waste. Ingenious design solutions help meet these challenges. However, some manufacturers still struggle to balance performance and compliance. This constant evolution highlights the complexity of choosing hydraulic rotary actuators. The pressures of regulations can motivate innovation yet lead to unexpected shortcomings in actuator longevity and reliability.

Hydraulic Actuator Use by Industry (Percentage)

This chart illustrates the percentage of hydraulic actuator usage across various industries, highlighting the significance of selecting hydraulic rotary actuators in projects affected by industry standards and regulations.

Case Studies: Successful Implementation of Hydraulic Rotary Actuators

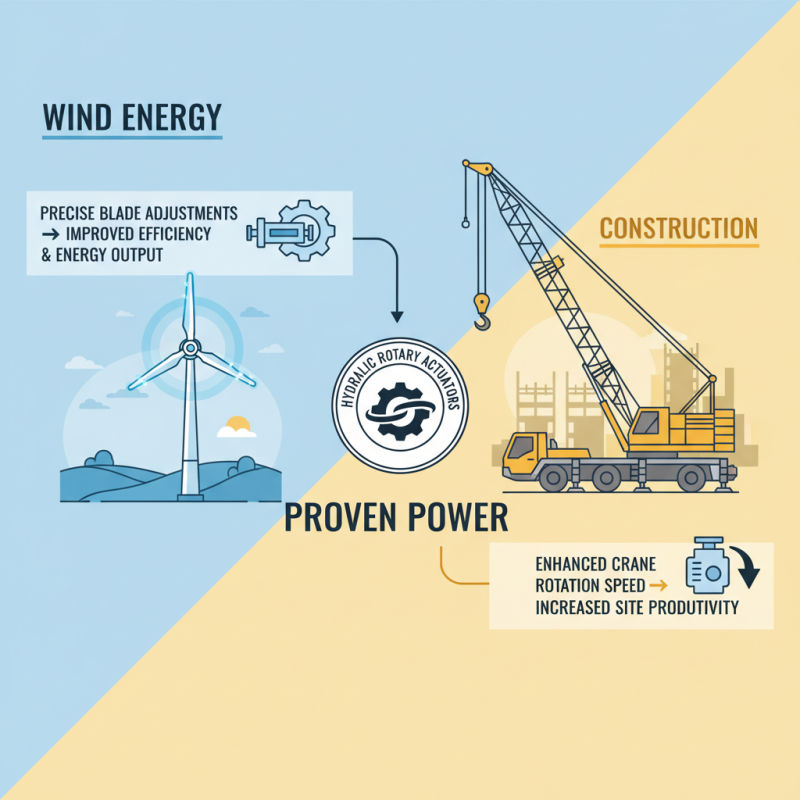

Hydraulic rotary actuators have proven their worth in various applications. For instance, in a wind turbine project, these actuators enabled precise blade adjustments. This improved efficiency and energy output significantly. In another case, a construction company used hydraulic actuators to enhance their crane’s rotation speed. The result was a substantial boost in productivity on site.

When considering hydraulic rotary actuators, think about the specific requirements. Evaluate the torque, speed, and control needed for your project. Each detail can make a difference.

Tip: Always test prototypes before full-scale implementation. This helps identify potential issues early. A minor flaw in design can lead to significant setbacks. Reflection on past projects often reveals overlooked areas. Consider what adjustments could enhance future outcomes.

Related Posts

-

Why Pneumatic Rotary Actuators Are Essential for Modern Automation

-

Exploring Pneumatic Rotary Actuator Innovations at 2025 China Import and Export Fair

-

Unlocking Precision: How Hydraulic Rotary Actuators Revolutionize Industrial Automation

-

Top 10 Hydraulic Actuators: Boost Your Machinery Efficiency Today

-

2026 Top Hydraulic Actuator Types for Your Applications?

-

2026 How to Choose the Best Pneumatic Rotary Actuator for Your Needs?