Blog

How to Choose a Pneumatic Butterfly Valve for Your Application?

Choosing the right pneumatic butterfly valve is crucial for optimizing system performance. These valves control the flow of fluids and gases, making their selection vital in various industries. With numerous options available, finding the best fit for your application requires careful consideration.

A clear understanding of your specific needs will help streamline the selection process. Factors such as pressure tolerance, size, and material affect performance. For instance, a lightweight valve might be ideal for some environments, while others require robust materials. Paying attention to these details ensures long-term reliability.

However, it's easy to overlook these aspects. Perhaps you rush the decision or rely solely on past experiences. This approach could lead to inefficient solutions. Reflecting on your requirements and seeking expert advice can lead to better outcomes. In conclusion, a well-chosen pneumatic butterfly valve enhances efficiency and reduces operational issues.

Understanding the Basics of Pneumatic Butterfly Valves

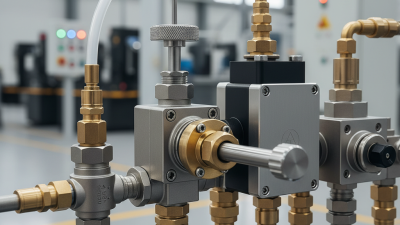

Pneumatic butterfly valves are essential in many industries. They control the flow of fluids effectively. Understanding their basics is crucial before making a choice. These valves consist of a disc that rotates to open or close. When the disc is parallel to the flow, it allows full passage. When turned 90 degrees, it blocks the flow.

Installation and maintenance are key considerations. A poorly installed valve can lead to leaks and inefficiency. Regular checks are necessary to ensure functionality. Some might overlook the actuator's role. The type of actuator can affect performance. Electric or pneumatic options have their own pros and cons.

Choosing the right size is vital. An oversized valve can disrupt flow, leading to uneven pressure. Conversely, a valve that's too small restricts flow and can cause wear. Evaluating your system’s requirements is essential. Think about the medium and pressure levels. Ignoring these details can lead to costly mistakes. Understanding these fundamentals can guide your choices wisely.

Understanding Flow Characteristics of Pneumatic Butterfly Valves

This chart illustrates the flow characteristics of various sizes of pneumatic butterfly valves (in inches) measured in cubic feet per minute (CFM) at a specific pressure. It helps in understanding how valve size affects flow rate.

Key Factors to Consider When Selecting Pneumatic Butterfly Valves

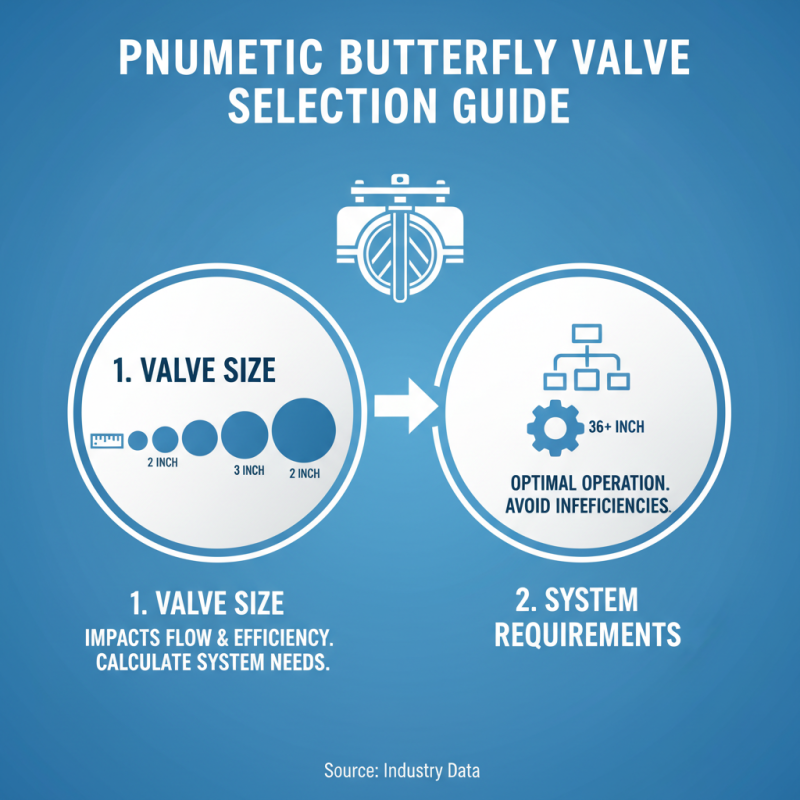

When selecting pneumatic butterfly valves, several key factors emerge. First, consider the valve size. The required size directly impacts flow rates and efficiency. According to industry data, valve diameters can range from 2 inches to over 36 inches. A precise calculation of the system requirements is essential, as improper sizing can lead to operational inefficiencies.

Material selection is another crucial aspect. Common materials include stainless steel, aluminum, and plastic. Each has different corrosion resistance levels. For instance, a stainless steel valve might suit corrosive environments better than plastic. However, plastic valves can perform well in less demanding applications. Assessing the medium being transported helps determine the best materials.

Finally, think about operating pressure and temperature. Most valves perform well within specific limits. Manufacturer reports indicate that pneumatic butterfly valves typically handle pressures up to 150 psi. Ensure the chosen valve can operate within the necessary conditions. Overlooking these elements may result in failures or suboptimal performance. Careful evaluation is critical for long-term reliability and efficiency.

Evaluating Compatibility with Your System Requirements

When selecting a pneumatic butterfly valve, compatibility with your system requirements is crucial. This means evaluating various factors, like pressure, temperature, and flow rates. A report by the Fluid Control Institute indicates that improper compatibility can lead to valve failure in more than 30% of cases. These failures often result in costly downtimes and maintenance.

Assess the materials used in the valve construction. Different media may require specific materials to avoid corrosion and ensure durability. For instance, valves used in corrosive environments may need a different coating than those in standard applications. The American Society of Mechanical Engineers (ASME) emphasizes the risk of using unsuitable materials. Overlooking this can lead to significant operational losses.

Another consideration is the actuator type. Pneumatic actuators can affect performance. They must match the valve's size and characteristics. According to a recent industry analysis, 25% of pneumatic valve malfunctions occur due to misalignment between the actuator and the valve. Regular evaluations of these components can prevent unexpected failures and enhance system efficiency.

Assessing Performance Features for Optimal Operation

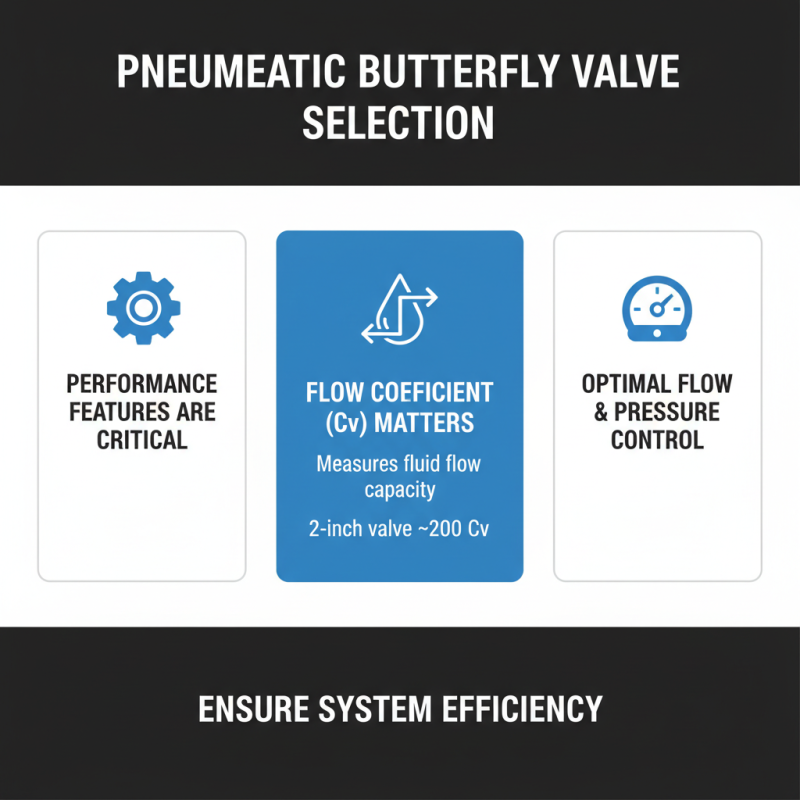

When selecting a pneumatic butterfly valve, performance features play a critical role. A valve’s flow coefficient (Cv) is essential. This measure indicates how much fluid can pass through. For example, a 2-inch valve typically has a Cv around 200. Proper Cv ensures optimal flow and pressure control in your system.

Material selection is another crucial factor. Common materials include stainless steel and PVC. Each material has its benefits and limitations. Stainless steel offers high durability and corrosion resistance. Meanwhile, PVC is lightweight and cost-effective but can be less durable under high temperature or pressure.

Tips: Always consider temperature and pressure ratings when choosing materials. This helps prevent premature failure.

Additionally, actuator compatibility is vital. Different actuators provide various levels of speed and control. A mismatch can lead to inefficiencies. For example, a valve might operate too slowly if paired improperly. Hence, proper actuator selection is key for reliability and performance.

In evaluating these features, ensure that you consider the specific requirements of your application. Small choices can have bigger implications. Sometimes, a practical test can reveal what detailed specifications cannot.

Tips: Test different configurations in real-world conditions. Observing performance can inform future decisions.

Maintenance and Durability Considerations for Long-Term Use

When selecting a pneumatic butterfly valve, maintenance and durability should be top priorities. Regular inspections are essential. Checking for wear and tear can prevent unexpected failures. Proper lubrication reduces friction and prolongs valve life. However, some users overlook this simple task. A neglected valve often leads to significant issues, including leaks and malfunctions.

Additionally, consider the environment in which the valve operates. Harsh conditions can affect performance. For example, high temperatures may degrade seals. Corrosive substances can damage materials. Using valves made from resistant materials can be beneficial. But, not all applications may provide ideal conditions. Sometimes, it is necessary to reassess the suitability of existing valves.

Lastly, understanding the frequency of operation is crucial. Constant cycling can wear out components quickly. If your application demands frequent use, upgrading to more durable options may be wise. Ultimately, creating a reliable maintenance schedule can improve the longevity of your pneumatic butterfly valves. Slacking on maintenance is a trap many fall into. Pay close attention to these factors for lasting performance.

Related Posts

-

Top 5 Types of Butterfly Valves You Need to Know for Optimal Performance

-

Understanding the Benefits of Butterfly Valves in Modern Industrial Applications

-

Top 5 Benefits of Using Pneumatic Butterfly Valves in Industrial Applications

-

Top Pneumatic Flow Control Valve Types Explained: Choosing the Right One

-

How to Choose the Right Pneumatic Butterfly Valve for Your Applications

-

Exploring the Future of Pneumatic Control Valves in 2025 Top Digital Innovations