Blog

How to Choose the Right Duplex Basket Strainer for Your Needs in 2025

When it comes to maintaining the efficiency and longevity of industrial systems, choosing the right duplex basket strainer is crucial. In 2025, as industries continue to evolve and face new challenges, the need for optimal filtration solutions is more significant than ever. Duplex basket strainers play an essential role in preventing the accumulation of unwanted particles in pipelines, thereby safeguarding pumps and other critical equipment from damage.

A proper selection of a duplex basket strainer not only enhances operational performance but also minimizes downtime and maintenance costs. Factors such as the materials of construction, screen size, and flow rate capacity must be carefully considered to match the specific requirements of an application. Additionally, understanding the varying types of duplex basket strainers available in the market will empower users to make informed decisions that align with their operational needs.

As we move further into 2025, this guide aims to highlight the key considerations and criteria for selecting the right duplex basket strainer, ensuring a seamless integration into your industrial processes. With the right knowledge and resources, users can confidently choose the most suitable solution tailored to their unique needs.

Understanding the Basics of Duplex Basket Strainers

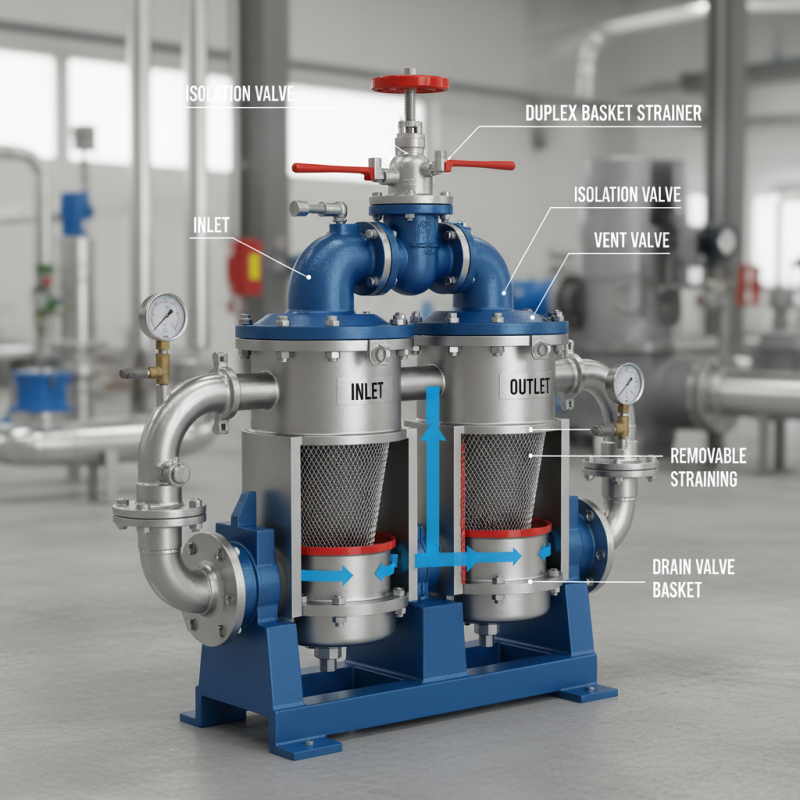

Duplex basket strainers are essential components in various industrial applications, designed to efficiently remove solid particles from liquids, thereby ensuring the smooth operation of downstream equipment. At their core, duplex basket strainers feature two separate filtering baskets housed within a single unit, allowing for continuous operation without the need for system shutdown during maintenance. This dual-chamber design enables one basket to filter while the other is cleaned or replaced, thus improving efficiency and minimizing downtime.

When selecting a duplex basket strainer, it's crucial to understand its fundamental components and functionality. The strainer typically consists of a sturdy body, inlet and outlet connections, and a removable basket designed to capture debris. The size and type of the basket are essential considerations, as they need to match the specific application requirements, including flow rate, pressure drop, and the type of contaminants expected. Additionally, the materials used for both the strainer body and the baskets should be compatible with the fluids being filtered, ensuring durability and resistance to corrosion or wear over time. Understanding these basics will help you make informed decisions that align with your operational needs in 2025 and beyond.

Duplex Basket Strainer Comparison in 2025

Key Factors to Consider When Choosing a Duplex Basket Strainer

When selecting the right duplex basket strainer for your needs in 2025, several key factors should be taken into consideration. First and foremost, assess the nature of the fluid being filtered. Understanding the viscosity, temperature, and chemical composition of the fluid will guide you in choosing a strainer that can handle the specific demands of your application, ensuring optimal performance.

Another crucial factor to consider is the flow rate. Each duplex basket strainer has a maximum flow capacity, and selecting one that aligns with your system's requirements is essential to avoid bottlenecks and ensure efficient operation. Additionally, consider the ease of maintenance; models with quick-opening mechanisms simplify cleaning and reduce downtime, making them more practical for frequent use.

Tips: Always consult with technical specifications and industry standards relevant to your application to ensure compliance and compatibility. Additionally, think about the installation space available; some duplex basket strainers have larger footprints than others, so planning accordingly can save time and resources. Ultimately, balancing these factors will help you choose a duplex basket strainer that not only meets your current needs but is also adaptable for future requirements.

Comparing Material Options for Duplex Basket Strainers

When selecting a duplex basket strainer, the choice of materials is crucial in ensuring optimal performance and longevity. Common materials for duplex strainers include stainless steel, carbon steel, and plastic composites. According to a recent industry report from the American Institute of Chemical Engineers, stainless steel is favored for its corrosion resistance and durability, making it ideal for harsh environments typically found in the oil and gas industry. Approximately 60% of maintenance professionals prefer stainless steel for applications involving corrosive fluids, underscoring its reliability in long-term service.

Carbon steel offers a cost-effective alternative for less aggressive applications, though it requires proper coatings to enhance its resistance to rust. Statistics from the Fluid Control Research Group indicate that while carbon steel is chosen for 25% of applications, its necessity for regular maintenance might discourage its use in demanding scenarios. In contrast, plastic composite strainers are becoming increasingly popular in industries dealing with less aggressive substances, offering a lightweight solution while being resistant to chemicals and UV exposure.

**Tips:** When choosing a duplex basket strainer, assess the fluid characteristics and environmental conditions first. Opt for stainless steel in corrosive applications, and consider the total cost of ownership, including maintenance needs. Additionally, evaluate the temperature and pressure ratings to ensure compatibility with your system, which can significantly impact the lifespan of the strainer.

How to Choose the Right Duplex Basket Strainer for Your Needs in 2025 - Comparing Material Options for Duplex Basket Strainers

| Material | Corrosion Resistance | Temperature Range | Maintenance Needs | Cost |

|---|---|---|---|---|

| Stainless Steel | High | -100°F to 800°F | Low | $$$ |

| Carbon Steel | Moderate | -40°F to 400°F | Medium | $$ |

| Bronze | High | -60°F to 600°F | Low | $$$ |

| PVC | Low | -30°F to 150°F | Medium | $ |

Evaluating Flow Rate and Capacity Requirements

When selecting a duplex basket strainer, it's essential to evaluate the flow rate and capacity requirements that align with your specific application. The flow rate will determine the size and design of the strainer you need, ensuring that it can handle the volume of liquid passing through without causing significant pressure drops. To accurately assess your flow requirements, consider conducting a detailed analysis of your system’s operational parameters, including variations in peak flow and the typical inlet conditions.

Tips: Always refer to the manufacturer's specifications and guidelines to ensure that the chosen strainer meets your application’s flow rate demands. Additionally, you may want to consider factors such as the type of liquid being filtered, as different liquids can have varying impacts on strainer performance and maintenance.

Alongside flow rate, capacity is another crucial aspect to consider. Duplex basket strainers are designed for continuous operation and must be able to accommodate the total volume of particulate that will be filtered out of the liquid. Evaluate your system's maximum debris load and ensure that the strainer can handle these conditions without maintenance disruptions. A smart choice could be opting for a model with easy access for cleaning, allowing for routine maintenance without significant downtime.

Tips: Regularly monitor your system and be proactive about maintenance schedules to prolong the lifespan of your strainer. This will help avoid costly interruptions in your operations.

Maintenance Tips for Optimal Performance of Duplex Basket Strainers

When it comes to maintaining duplex basket strainers for optimal performance, regular inspection and cleaning are essential. According to a report by the American Water Works Association, approximately 20% of system failures in industrial processes can be attributed to clogged strainers. To prevent this, operators should establish a maintenance schedule that involves checking the strainers at least monthly, depending on the fluid characteristics and particle load. This proactive approach not only reduces unplanned downtime but also enhances the efficiency of the entire system.

In addition to regular inspections, proper cleaning is crucial. It is recommended to use a soft brush or a specialized cleaning tool to remove debris without damaging the strainer. A study conducted by the International Society of Automation highlighted that systems performing regular maintenance showed a 30% increase in overall efficiency compared to those neglected. Furthermore, monitoring the pressure drop across the strainer can provide real-time insights into its condition; a sudden increase in pressure drop may indicate that preventive maintenance is required sooner than scheduled. Such measures ensure that duplex basket strainers continue to perform effectively, ultimately leading to cost savings and improved process reliability.

Related Posts

-

Top 5 Benefits of Using Pneumatic Butterfly Valves in Industrial Applications

-

Exploring the Future of Basket Strainers at the 138th Canton Fair 2025 in China

-

Understanding Hydraulic Actuators: How They Improve Efficiency in Industrial Automation by 30%

-

Understanding the Importance of Spring Check Valve in Modern Plumbing Systems

-

How to Choose the Right Stainless Steel Check Valve for Your Plumbing Needs

-

Exploring Air Actuator Innovations at the 138th Canton Fair 2025 in China