Blog

How to Choose the Right Pneumatic Butterfly Valve for Your Applications

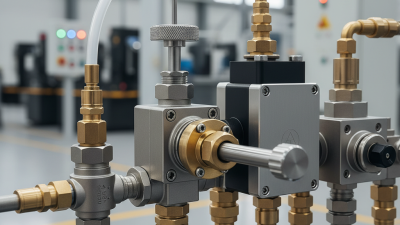

Choosing the right pneumatic butterfly valve for your applications is a critical decision that can significantly impact efficiency and reliability in various industrial processes. Pneumatic butterfly valves are widely recognized for their ability to control fluid flow effectively while providing the benefits of quick operation and low-pressure drop. However, selecting the appropriate valve entails several considerations, including the specific requirements of the application, the characteristics of the media being handled, and the operational environment.

When evaluating a pneumatic butterfly valve, it is essential to understand the various factors that influence performance and suitability. These include the valve size, connection type, and material compatibility with the fluid. Additionally, factors such as the desired flow rate, pressure conditions, and the potential for corrosive or abrasive media must be taken into account. By carefully assessing these criteria, engineers and operators can ensure that they choose a pneumatic butterfly valve that meets their operational needs and enhances system performance.

In summary, the process of selecting the right pneumatic butterfly valve demands thorough research and consideration of multiple factors. By understanding the unique requirements of your application and the specific features of available valves, you can make an informed decision that optimally meets your operational goals.

Overview of Pneumatic Butterfly Valves and Their Applications

Pneumatic butterfly valves are essential components in various industries, widely employed for their ability to efficiently regulate flow in pipelines. These valves operate by rotating a disk to control the passage of fluid, making them a preferred choice in sectors such as water treatment, oil and gas, and chemical processing. According to a report by MarketsandMarkets, the pneumatic valve market is projected to reach $5.2 billion by 2026, illustrating the growing reliance on automated systems that enhance process control and efficiency.

The versatility of pneumatic butterfly valves allows them to operate in diverse applications, ranging from handling viscous slurries to managing high-temperature steam. Their lightweight design and quick-acting capabilities make them suitable for both on-off and throttling services. For instance, in the water and wastewater industry, these valves contribute to effective flow management, facilitating the treatment process. The increasing demand for fluid control solutions that provide reliability and high performance further underscores the importance of selecting the right pneumatic butterfly valve tailored to specific operational needs.

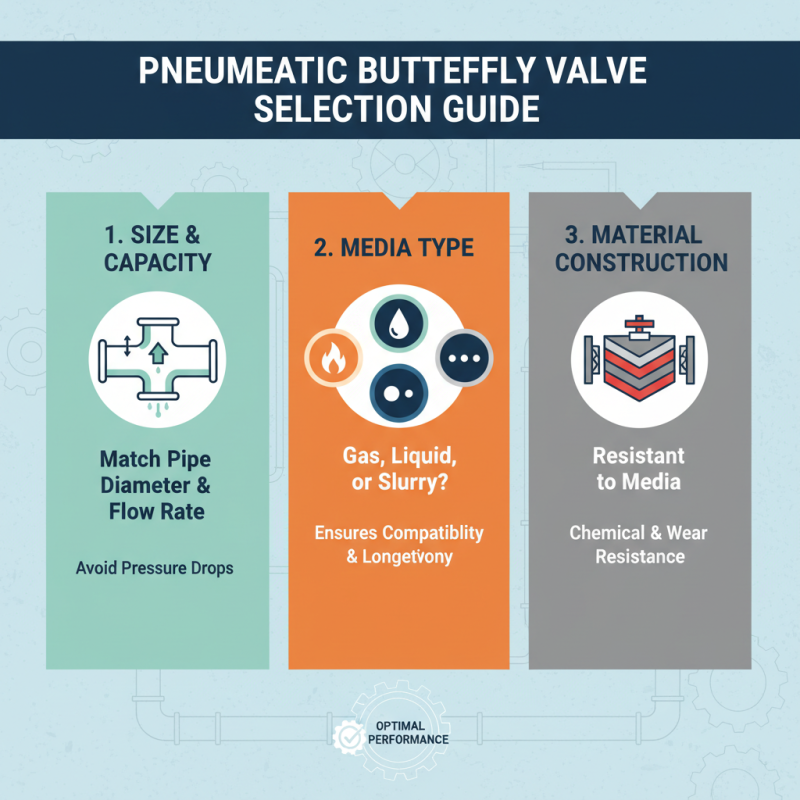

Key Factors to Consider in Selecting a Pneumatic Butterfly Valve

When selecting a pneumatic butterfly valve for your application, several key factors should be at the forefront of your decision-making process. First and foremost, consider the size and capacity requirements. The valve must match the specifications of your piping system, including diameter and flow rate. An incorrectly sized valve can lead to inefficiencies, potentially causing pressure drops or flow inconsistencies that can jeopardize operational effectiveness. Understanding the media type being controlled, whether it's a gas, liquid, or slurry, is also crucial as it dictates the material needed for the valve construction to ensure compatibility and longevity.

Another important factor is the valve’s pressure rating and temperature range. Different applications may subject valves to varying degrees of pressure and temperature, necessitating materials that can withstand such conditions without degrading. Additionally, evaluate the actuation method. Pneumatic valves come with various actuation styles, including double-acting or spring-return options, each suited to different operational scenarios. Finally, consider the environment in which the valve will operate. Factors like humidity, exposure to corrosive substances, and extreme temperatures can significantly affect valve performance. Addressing these factors will lead to a more effective selection process, ensuring the pneumatic butterfly valve meets your specific operational requirements efficiently.

Material Considerations: Corrosion Resistance and Durability

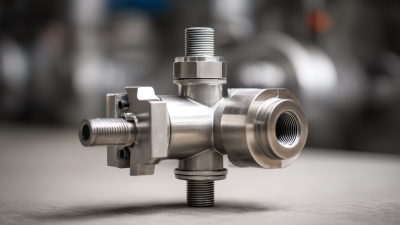

When selecting a pneumatic butterfly valve, understanding the material considerations is crucial for ensuring both corrosion resistance and durability. The valve's long-term performance heavily relies on the materials used in its construction. Common materials for butterfly valves include stainless steel, carbon steel, and various plastics, each offering unique benefits depending on the application environment. For instance, stainless steel valves are renowned for their superior resistance to corrosion, making them suitable for use in harsh chemicals and high-temperature applications. Conversely, plastic valves may be adequate for milder conditions, providing lightweight options that resist some corrosive elements.

Durability is another essential factor, as the valve must withstand constant use without significant wear or failure. High-quality materials can reduce the frequency of repairs and replacements, which is critical for maintaining operational efficiency and cost-effectiveness. It’s also important to consider the specific environmental factors, such as temperature fluctuations and exposure to aggressive chemicals, which can compromise the integrity of the valve over time. Therefore, evaluating both corrosion resistance and durability is vital when choosing a pneumatic butterfly valve, ensuring it will perform reliably and effectively throughout its service life.

Sizing Guidelines: Calculating Flow Requirements and Pressure Ratings

When selecting the appropriate pneumatic butterfly valve for your applications, one of the most critical steps is to accurately size the valve based on flow requirements and pressure ratings. According to industry standards, including data from organizations such as the American Society of Mechanical Engineers (ASME), calculations should begin with determining the necessary flow rate for the system, usually measured in gallons per minute (GPM) or cubic meters per hour (m³/h). The flow characteristics will guide you in selecting a valve that can handle the anticipated flow without excessive pressure drop or turbulence.

Pressure ratings are equally important, as they ensure the valve can withstand the operating conditions of the system. Typically, pneumatic butterfly valves come with pressure ratings categorized by classes such as ANSI Class 150, 300, and 600, which correspond to different applications and materials. A detailed review of your system’s pressure requirements, often guided by safety factors, will help in choosing a valve that meets or exceeds these conditions.

**Tips**: When calculating flow requirements, consider using the formula Q = AV, where Q is the flow rate, A is the cross-sectional area of the valve, and V is the velocity of the fluid. Additionally, always consult industry guidelines or professionals to cross-verify calculations. Regularly monitor system pressure and flow rates to adapt your valve choice for future operational changes.

How to Choose the Right Pneumatic Butterfly Valve for Your Applications - Sizing Guidelines

| Valve Size (inches) | Flow Capacity (GPM) | Pressure Rating (psi) | Temperature Rating (°F) | Material |

|---|---|---|---|---|

| 2 | 100 | 150 | 180 | Ductile Iron |

| 3 | 150 | 150 | 200 | Stainless Steel |

| 4 | 200 | 150 | 200 | Aluminum |

| 6 | 400 | 300 | 250 | Carbon Steel |

| 8 | 600 | 150 | 300 | CPVC |

Performance Standards and Compliance in Pneumatic Valve Selection

When selecting a pneumatic butterfly valve, understanding the performance standards and compliance requirements is crucial for ensuring optimal functionality and safety in your application. Industry standards, such as those set by the International Organization for Standardization (ISO) and the American Society of Mechanical Engineers (ASME), provide essential guidelines that valves must meet to operate efficiently under varying conditions. Make sure to refer to these standards while assessing valve specifications, as compliance ensures that the valve will perform reliably and meet safety regulations pertinent to your industry.

**Tips:** When evaluating performance standards, consider factors such as pressure ratings, temperature allowances, and end connections. These elements can significantly affect the valve's performance in your specific application. Additionally, it's beneficial to review any certification requirements specific to your industry, as these will delineate the acceptable materials and construction practices for your pneumatic butterfly valve.

Another key consideration is the valve's operational performance in your system’s context. This includes assessing the actuator type, response time, and control capabilities. A thorough understanding of these performance criteria not only aids in selecting a valve that aligns with your operational demands but also ensures that it complies with necessary regulations. Conducting a comprehensive analysis of both performance standards and compliance issues is vital to ensure the longevity and reliability of your pneumatic butterfly valves in their intended applications.

Performance Standards of Pneumatic Butterfly Valves

Related Posts

-

How to Select the Best Butterfly Valve Type for Your Industrial Needs

-

Revolutionizing Industrial Automation with Cutting-Edge Pneumatic Valve Actuators

-

Understanding the Benefits of Butterfly Valves in Modern Industrial Applications

-

Top 5 Types of Butterfly Valves You Need to Know for Optimal Performance

-

Top Pneumatic Flow Control Valve Types Explained: Choosing the Right One

-

Why Understanding Pneumatic Flow Control Valves is Essential for Efficient Industrial Processes