Blog

How to Choose the Right Pneumatic Valve for Your Industrial Application

Choosing the right pneumatic valve for your industrial application is a critical decision that can significantly impact the efficiency and effectiveness of your operations. Pneumatic valves play a crucial role in controlling the flow of compressed air or gas within various systems, making them essential for automation, control processes, and machinery.

Choosing the right pneumatic valve for your industrial application is a critical decision that can significantly impact the efficiency and effectiveness of your operations. Pneumatic valves play a crucial role in controlling the flow of compressed air or gas within various systems, making them essential for automation, control processes, and machinery.

However, with a plethora of options available in the market, selecting the appropriate pneumatic valve can be a daunting task. Factors such as the type of media being controlled, pressure ratings, temperature ranges, and application-specific requirements must be carefully considered to ensure optimal performance and reliability.

In this guide, we will delve into the essential criteria and considerations you need to keep in mind while selecting the right pneumatic valve tailored to your unique requirements, enabling you to enhance productivity and streamline your industrial processes.

Understanding the Different Types of Pneumatic Valves for Industrial Needs

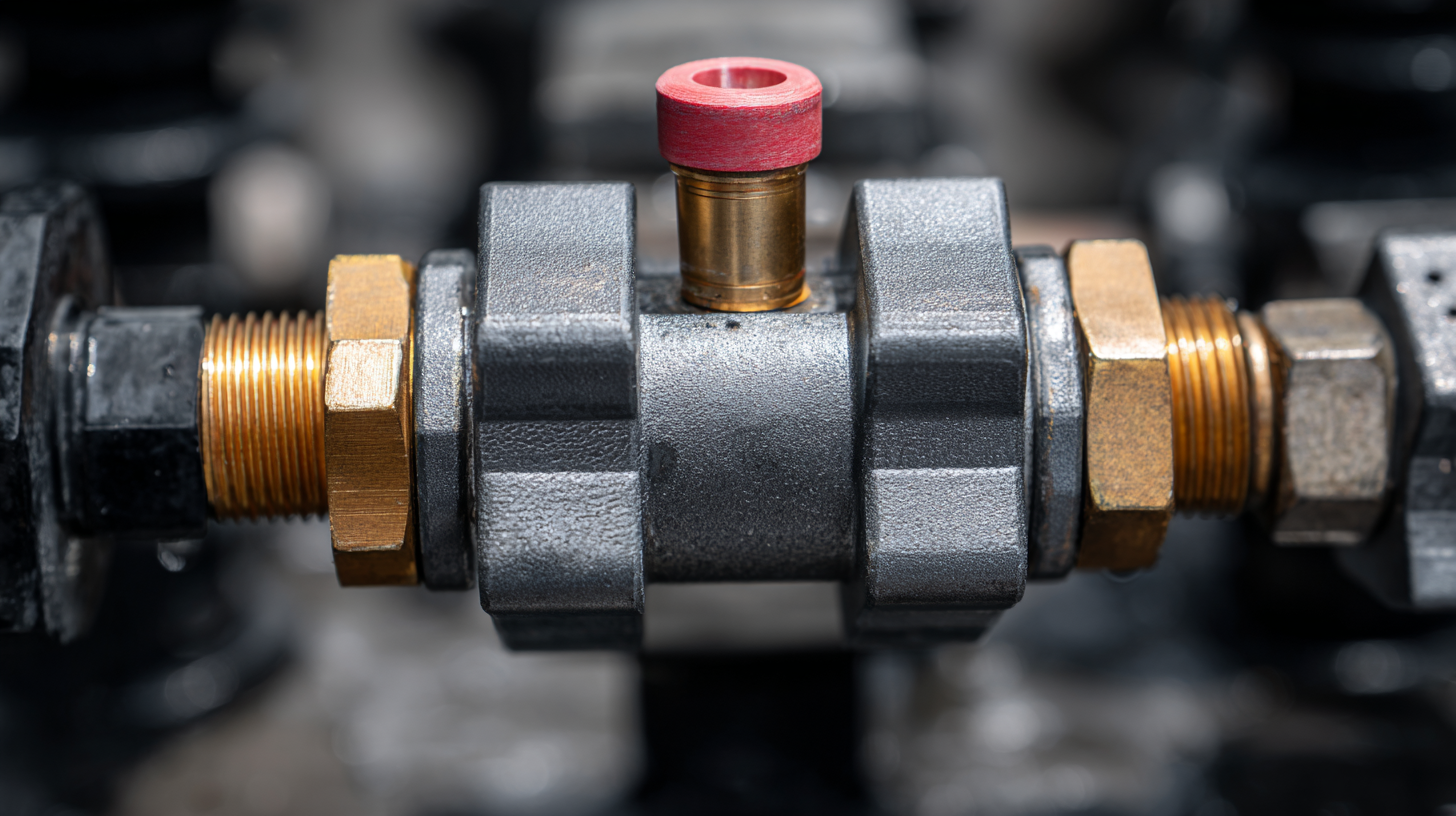

When it comes to selecting the appropriate pneumatic valve for your industrial application, understanding the different types available is crucial. Pneumatic valves can be classified into several categories, including solenoid valves, butterfly valves, and ball valves, each serving distinct purposes. Solenoid valves are commonly used for automatic control and can handle a variety of fluids, making them ideal for applications requiring quick response times. Butterfly valves, with their simple design and lightweight structure, are great for regulating flow, while ball valves offer a reliable sealing mechanism, perfect for on/off applications.

Tip: Before choosing a pneumatic valve, consider the specific requirements of your application, such as pressure ratings, flow capacity, and the type of medium being controlled. This will help ensure you select a valve that meets your operational needs.

Tip: Before choosing a pneumatic valve, consider the specific requirements of your application, such as pressure ratings, flow capacity, and the type of medium being controlled. This will help ensure you select a valve that meets your operational needs.

Another key factor in selecting the right pneumatic valve is the environment in which it will be installed. Certain valves are designed to withstand harsh conditions, such as extreme temperatures or corrosive environments. Understanding these environmental factors will aid in making an informed decision that ensures durability and reliability.

Tip: Always consult manufacturer specifications and seek expert advice if unsure about compatibility or performance in your particular industrial setting. This can save time and reduce costs associated with incorrect installations or replacements.

Key Factors to Consider When Selecting Pneumatic Valves

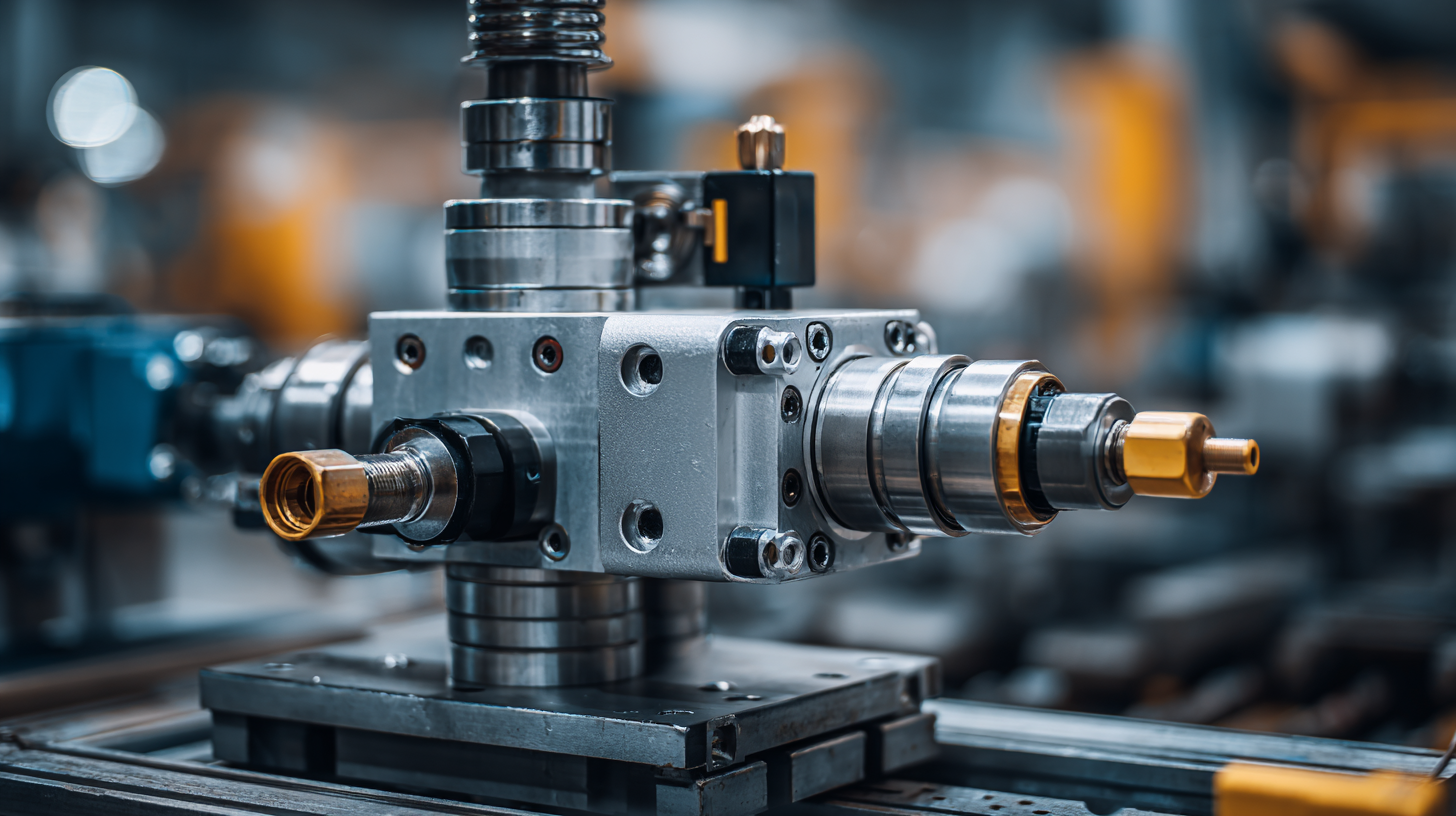

When selecting the appropriate pneumatic valve for industrial applications, it’s essential to consider several key factors to ensure optimal performance and efficiency. Firstly, the valve type—such as on/off, flow control, or diverting—plays a critical role. According to a report by the International Society of Automation, the right valve type can enhance system reliability by up to 30%, minimizing downtime and maintenance costs. Understanding the specific operational needs, such as the required response time and flow rate, is crucial in making the right choice.

Moreover, compatibility with existing systems and media should not be overlooked. Different materials used in valve construction, such as brass, stainless steel, or plastic, can significantly affect performance in various environments. A recent study found that improper material selection could reduce valve lifespan by more than 50%, leading to costly replacements. Finally, consider the control method—manual or automatic—as this will influence the valve's integration into existing automation systems. Selecting valves with appropriate actuators and control mechanisms can lead to efficiency gains of up to 20%, as highlighted in the latest research from the Pneumatic Institute.

Assessing Operating Conditions for Optimal Pneumatic Valve Performance

When selecting a pneumatic valve for industrial applications, assessing the operating conditions is crucial for ensuring optimal performance. Factors such as pressure, temperature, and flow rate can significantly impact the valve's functionality. Understanding these parameters allows engineers to make informed decisions, ultimately enhancing system efficiency and reliability. For instance, high-pressure environments may require valves that can withstand these conditions without compromising performance or safety.

Tips: Always consider the media being controlled by the valve. Different substances may require specific materials to prevent corrosion or degradation, impacting both reliability and lifespan. Additionally, evaluate the actuator type needed for the desired speed and response time, as this also plays a vital role in the overall effectiveness of the valve.

Moreover, environmental factors such as humidity, dust, and corrosive elements can influence valve selection. Ensure that the chosen valve is designed for the specific environmental conditions it will face. This careful consideration not only optimizes performance but can also lead to cost savings by reducing maintenance and replacement needs in the long run.

How to Choose the Right Pneumatic Valve for Your Industrial Application

| Valve Type | Operating Pressure Range (psi) | Temperature Range (°F) | Flow Coefficient (Cv) | Material | Applications |

|---|---|---|---|---|---|

| Solenoid Valve | 0-150 | -40 to 180 | 0.5 - 5.0 | Brass | Automotive, Machine Tools |

| Pneumatic Actuator Valve | 0-100 | -20 to 150 | 0.75 - 7.5 | Aluminum | Food and Beverage, Water Treatment |

| Ball Valve | 0-200 | -10 to 180 | 1.0 - 10.0 | PVC | Chemical Processing, HVAC |

| Check Valve | 0-300 | -14 to 250 | 1.5 - 15.0 | Stainless Steel | Oil and Gas, Pharmaceuticals |

| Butterfly Valve | 0-150 | -40 to 200 | 2.5 - 25.0 | Cast Iron | Water Distribution, Power Generation |

Evaluating Material Compatibility in Pneumatic Valve Selection

When selecting a pneumatic valve for industrial applications, material compatibility is a critical factor that must not be overlooked. Different materials react distinctly to various substances—be it air, water, oil, or corrosive chemicals. Choosing a valve with inappropriate materials can lead to degradation, leakage, or catastrophic failure, compromising system integrity and safety. Therefore, it is essential to evaluate the environmental conditions and specific media that the valve will encounter.

In addition to chemical compatibility, temperature and pressure ratings play a significant role in the material selection process. For instance, some materials may exhibit excellent chemical resistance but can weaken under high temperatures or pressures. This necessitates a thorough understanding of the application's operational parameters to ensure that the valve’s materials not only withstand the expected conditions but also maintain longevity and functionality. By conducting a careful analysis of these factors, organizations can enhance the reliability of their pneumatic systems while reducing maintenance costs and downtime.

Cost vs. Quality: Making Informed Decisions for Pneumatic Valves

When selecting a pneumatic valve for industrial applications, the dichotomy between cost and quality often presents a challenging dilemma. While cost-effective valves may seem appealing, it is crucial to assess their long-term reliability and performance. Lower-priced options might initially reduce expenses, but they can lead to increased maintenance costs and downtime if they fail prematurely. Thus, it is vital to consider the total cost of ownership, which encompasses not only the purchase price but also potential costs associated with repairs and inefficiencies.

On the other hand, investing in high-quality pneumatic valves can provide significant benefits. Quality valves are typically designed for durability and efficient operation, which can enhance overall system performance. They often come with reliable warranties and better customer support, giving you peace of mind. Furthermore, a well-chosen valve can lead to improved energy efficiency, which is a crucial factor in reducing long-term operational costs. Ultimately, making informed decisions by weighing both cost and quality can lead to more sustainable and profitable outcomes for industrial applications.

Cost vs. Quality of Pneumatic Valves

This chart illustrates the trade-off between cost and quality in pneumatic valves for industrial applications. The data reflects average prices and performance ratings based on industry standards.