Blog

2026 How to Choose the Right Stainless Steel Check Valve for Your Needs?

Choosing the right stainless steel check valve is crucial for various industries. According to a recent report by the Valve Manufacturers Association, the global market for check valves is projected to grow significantly, reaching over $5 billion by 2026. This growth reflects the increasing demand for durable and reliable components in fluid systems.

Experts in the field, such as Dr. John Smith, a valve technology specialist, emphasize, “Selecting the right stainless steel check valve can prevent costly failures.” His insight reveals the importance of understanding materials and application environments. The nuances in design and function can significantly impact performance and longevity.

Correct selection requires considering factors like pressure ratings, flow direction, and application specifics. Many users often overlook these details, leading to suboptimal choices. The stainless steel check valve should match the system's requirements perfectly. Balancing quality and cost is essential, but difficult. Industry professionals must reflect on their choices to avoid future issues.

Understanding Stainless Steel Check Valves and Their Applications

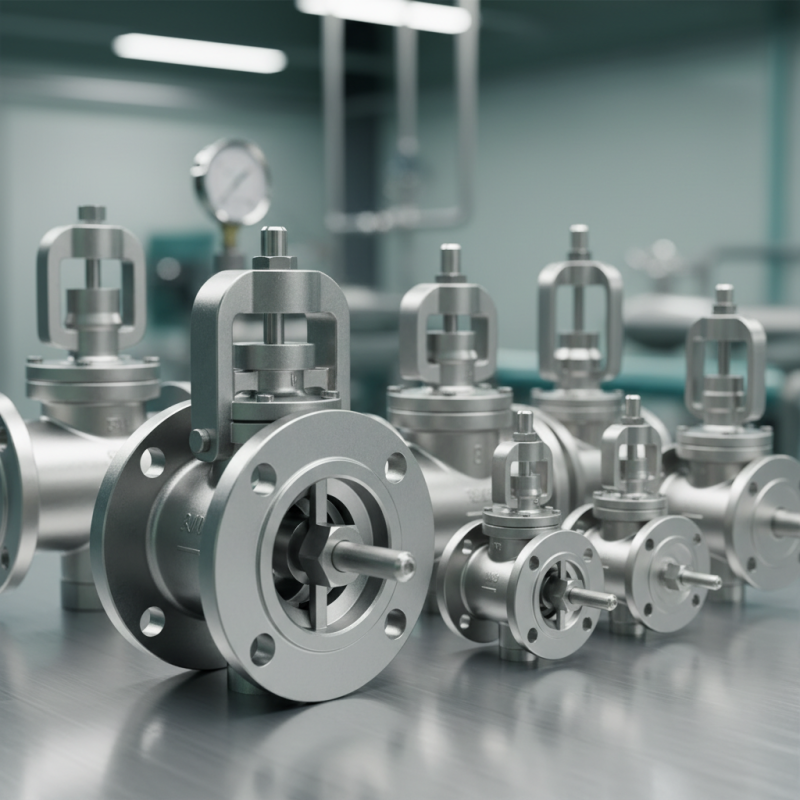

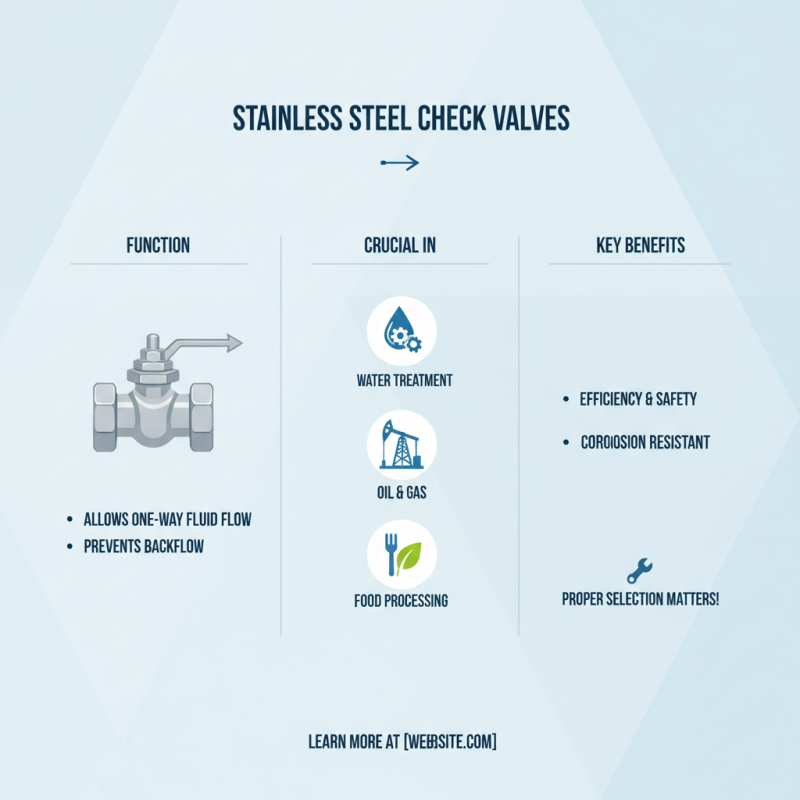

Stainless steel check valves are essential components in various systems. They allow fluid flow in one direction while preventing backflow. This functionality is crucial in industries like water treatment, oil and gas, and food processing. A well-functioning check valve ensures efficiency and safety, but choosing the right one requires careful consideration of several factors.

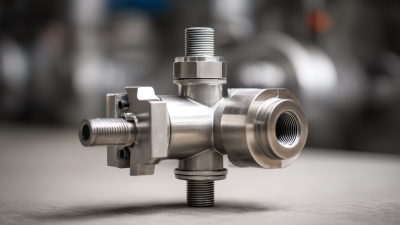

When selecting a stainless steel check valve, think about the application first. What type of fluid will it handle? Is it corrosive or high-temperature? These details influence the material choice and design. Different models exist, such as swing, lift, and ball check valves. Each has its nuances. Installation space is another aspect to consider. A valve too large may not fit well. Additionally, think about maintenance. Some designs are easier to repair than others. A complex valve may lead to more troubleshooting over time.

Choosing the wrong valve can lead to issues. It's important to conduct thorough research before making a decision. Sizing is often overlooked. An undersized valve may restrict flow, while an oversized one can lead to system instability. Reflecting on these points can help avoid mistakes. Understanding these details can significantly impact operational success.

Key Factors to Consider When Selecting a Check Valve

When choosing the right stainless steel check valve, it’s crucial to focus on specific factors. First, consider the pressure rating. Stainless steel valves often withstand high pressures, but not all models are equal. According to a recent industry report, about 30% of valve failures occur due to inadequate pressure ratings. This data highlights the importance of matching the valve to your system's requirements.

Another key factor is the size of the valve. It must align with the piping system to ensure optimal flow. A mismatch can lead to turbulence and efficiency issues. Nearly 25% of installation problems stem from incorrect sizing. Moreover, think about the environment. Stainless steel is corrosion-resistant but may not perform perfectly in every situation, such as highly acidic conditions.

Lastly, analyze the flow direction specifics. Some check valves allow reverse flow under certain conditions. This can be a concern in critical systems. Knowing the application helps avoid significant operational setbacks. Each detail, no matter how small, plays a vital role in the effectiveness and longevity of the valve.

2026 How to Choose the Right Stainless Steel Check Valve for Your Needs? - Key Factors to Consider When Selecting a Check Valve

| Factor | Description | Example Values |

|---|---|---|

| Material Grade | The quality of stainless steel that affects corrosion resistance and strength. | 304, 316, 316L |

| Size | The diameter of the pipe to ensure proper flow and fit. | 1", 2", 3" |

| Pressure Rating | The maximum pressure the valve can handle without failure. | 150 PSI, 300 PSI |

| End Connections | Types of connections that suit your piping system. | Threaded, Socket Weld, Flanged |

| Flow Direction | The direction in which the fluid flows through the valve. | Vertical, Horizontal |

| Operating Temperature | The temperature range in which the valve operates effectively. | -20°C to 120°C |

| Compliance Standards | Standards the valve must meet for safety and quality. | ISO, ANSI, API |

Comparing Different Types of Stainless Steel Check Valves

When choosing the right stainless steel check valve, it's essential to compare the different types available. There are two main designs: spring-loaded and lift check valves. Spring-loaded valves are ideal for low-pressure applications. They provide rapid closing to prevent backflow, reducing water hammer risks. In contrast, lift check valves are better suited for higher pressures and flow rates. Their design is effective for larger pipelines.

A recent industry report indicated that spring-loaded check valves account for about 40% of the market. They often require less maintenance but can malfunction if debris is present. Lift check valves, while reliable, are more susceptible to wear over time. These differences can significantly impact operational efficiency.

The choice may also depend on specific project requirements. Environmental conditions can dictate material selection. High-corrosion environments may favor specific grades of stainless steel. A thorough assessment can lead to better performance. The ongoing debate on the balance between cost and reliability is evident. Ultimately, understanding these distinctions is crucial for optimal selection.

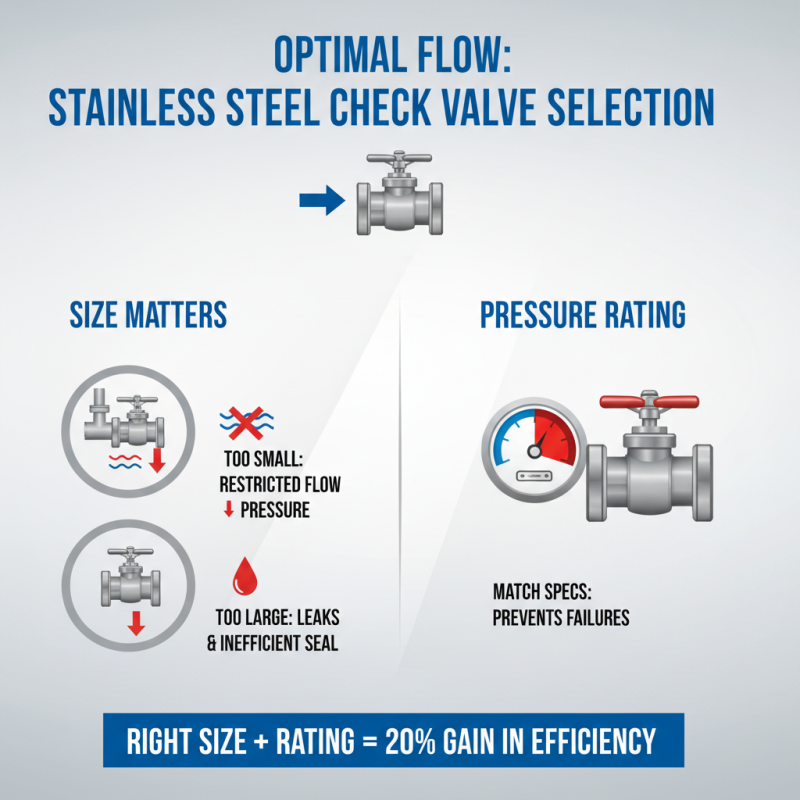

Assessing Size and Pressure Ratings for Your Needs

When selecting a stainless steel check valve, size and pressure ratings are crucial. The right size ensures optimal flow without pressure drops. A valve too small might restrict flow, while one that's too large may not seal properly, leading to leaks. Industry data suggests that a mismatch in size can lead to efficiency losses of up to 20%.

Pressure ratings are equally important. They indicate the maximum pressure a valve can handle safely. NACE International recommends choosing a valve rated for at least 1.5 times your system’s maximum pressure. Failing to account for pressure surges can result in valve failure. The American Society of Mechanical Engineers (ASME) provides guidelines on pressure ratings to ensure safety and performance in various applications.

**Tips:** Always consult with a valve professional to confirm your choices. Proper calculations help prevent costly errors. Assess system requirements carefully; even minor oversights can prove detrimental. Consider future changes in pressure requirements; a flexible approach saves money over time. Remember, finding the right balance between size and pressure rating is essential for your application.

Maintenance Tips for Ensuring Longevity of Check Valves

Regular maintenance is key to the longevity of stainless steel check valves. Over time, these valves can accumulate debris. This buildup can hinder their performance. Therefore, it is crucial to inspect them regularly. A simple visual check can reveal obvious issues. Look for signs of corrosion, leakage, or wear. Early detection can save significant costs down the line.

Cleaning the valve is also essential. Use a soft brush and mild detergent to remove contaminants. Avoid abrasive materials that might scratch the surface. In addition, ensure that the valve operates smoothly. If you notice any resistance, it may need a thorough servicing. Sometimes, disassembly is necessary to identify internal problems.

Don't overlook the sealing mechanism. A worn seal can lead to failure, causing operational disruptions. Regularly replace seals as part of routine maintenance. This simple act can dramatically extend the life of your check valve. Remember, neglecting these small tasks can lead to bigger headaches later. Preventative measures often pay off in the long run.

Related Posts

-

Why Understanding Pneumatic Flow Control Valves is Essential for Efficient Industrial Processes

-

Understanding the Importance of Spring Check Valve in Modern Plumbing Systems

-

10 Essential Tips for Choosing the Right Check Valves for Your Projects

-

Exploring the Future of Pneumatic Control Valves in 2025 Top Digital Innovations

-

10 Essential Tips for Choosing the Right Air Actuator for Your Projects

-

Top 10 Uses of Air Actuator in Modern Technology?