Blog

How to Choose the Right Pneumatic Actuator for Your Application in 2025

In the ever-evolving landscape of industrial automation, the selection of an appropriate pneumatic actuator stands as a critical decision for engineers and project managers alike. A pneumatic actuator, which utilizes compressed air to produce mechanical motion, is vital in a variety of applications ranging from manufacturing processes to robotic systems. As the demands of various industries continue to grow and evolve in 2025, understanding the specific requirements of an application becomes increasingly essential to harness the full potential of these devices.

Choosing the right pneumatic actuator involves careful consideration of factors such as operating pressure, stroke length, and environmental conditions. With advancements in technology, options are becoming increasingly diverse, and the performance capabilities of pneumatic actuators are improving. This not only enhances efficiency but also affects the overall performance of the systems they are integrated into. Therefore, it is important to thoroughly assess the application needs and limitations before making a decision. By doing so, one can ensure that the selected actuator aligns perfectly with the operational goals and provides optimal functionality for enhanced productivity and reliability in modern applications.

Understanding the Basics of Pneumatic Actuators and Their Applications

When selecting the right pneumatic actuator for your application, it’s essential to first understand the basics of how these devices function. Pneumatic actuators are mechanisms that use compressed air to produce mechanical motion. They are ideal for applications where high speed and precise control are required, such as in manufacturing and automation processes. The actuator converts the energy of compressed air into linear or rotary motion, making it versatile for various operational needs.

Tips: Consider the specific requirements of your application, including force, speed, and travel distance. These factors will help you determine the appropriate size and type of actuator. Additionally, examine the environment in which the actuator will operate. If exposure to dust, moisture, or extreme temperatures is a concern, opt for actuators that feature protective casings to ensure durability and longevity.

Another critical aspect is the compatibility of the actuator with other components in your system. Air supply regulations, control options, and mounting configurations play vital roles in the selection process. It’s important to ensure that the actuator's specifications align with your system's requirements to enhance performance and reduce the risk of operational failures.

Tips: Always consult technical documentation and, if possible, speak with professionals who can provide insights specific to your industry needs. Testing your selection in a controlled environment can also help identify any potential issues before full-scale implementation.

Pneumatic Actuator Selection for 2025 Applications

Key Factors to Consider When Choosing a Pneumatic Actuator

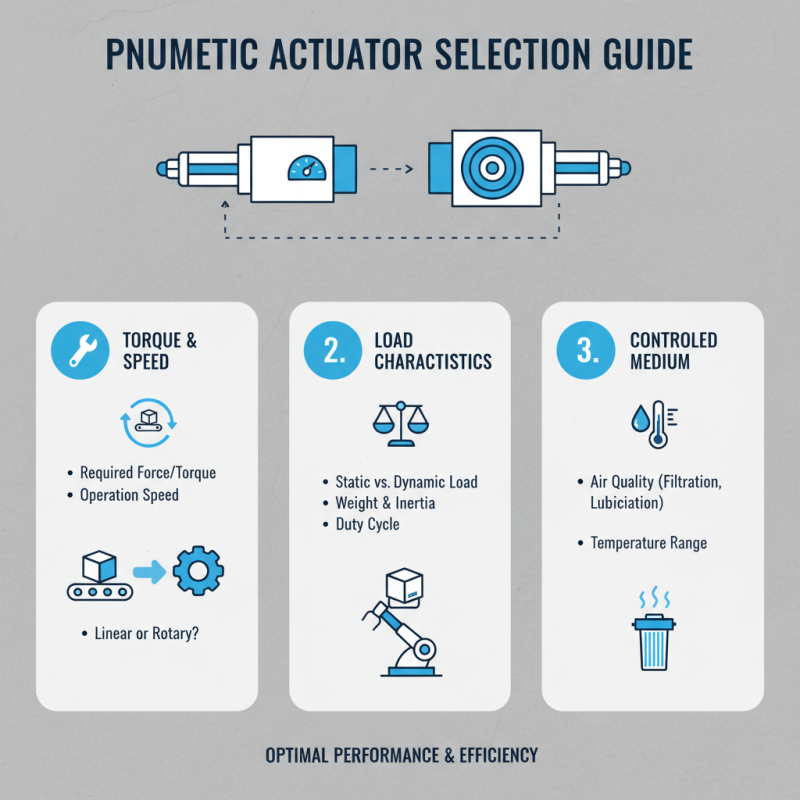

When selecting the right pneumatic actuator for your application, several key factors must be considered to ensure optimal performance and efficiency. First, assess the required torque and speed specifications based on your application’s needs. Understanding the load characteristics and the type of operation—whether it be linear or rotary—is crucial. Additionally, the medium being controlled, such as air quality or temperature, may influence the design and materials of the actuator to ensure compatibility and durability.

Another important aspect to consider is the installation environment. Factors such as ambient temperature, humidity, and potential exposure to corrosive substances can significantly impact the actuator's lifespan and functionality. It is also essential to evaluate the available control options, ensuring the actuator can be easily integrated with your existing systems. Lastly, consider maintenance requirements and the ease of access for servicing, as these can affect long-term operational costs and efficiency. By thoroughly analyzing these factors, you can select a pneumatic actuator that meets your application's specific demands while ensuring reliability and performance.

Types of Pneumatic Actuators and Their Specific Advantages

When selecting a pneumatic actuator for specific applications, understanding the various types and their advantages is crucial. One of the most common types is the Piston Actuator, known for its robust design and high torque output. These actuators excel in applications requiring powerful movement, making them suitable for valves and heavy-duty machinery. Their simple construction also allows for easier maintenance and greater reliability over extended periods.

Diaphragm actuators, on the other hand, offer a different set of benefits, especially in applications where precision and control are paramount. They are designed to provide smooth operation and can be highly responsive to changes in pressure. This responsiveness makes them ideal for tasks that require fine-tuning, such as in the pharmaceutical or food processing industries, where maintaining strict control over flow rates is essential. The inherent flexibility of diaphragm actuators also allows them to handle a variety of media without compromising performance.

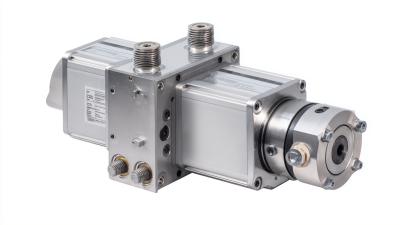

Lastly, Rotary actuators bring another dimension to pneumatic actuation, enabling rotational movement which is necessary in indexing and positioning applications. They typically require less space than linear actuators, making them ideal for compact installations. Their ability to provide a controlled rotation increases operational efficiency, especially in automated systems where precise positioning is critical. Each type of actuator presents unique advantages, and understanding these differences is key to selecting the right option for any specific application.

Evaluating Performance Specifications for Your Application Needs

When selecting a pneumatic actuator for your specific application in 2025, understanding performance specifications is crucial. Begin by evaluating key parameters such as stroke length, operating pressure, and response time, as these factors directly influence the actuator’s effectiveness in your system. For instance, an actuator with the correct stroke length will ensure that the movement of the device is precise and meets the operational demands. Furthermore, the compatibility of the actuator’s pressure ratings with your system’s requirements will determine its reliability and efficiency, avoiding potential failures under pressure fluctuations.

Next, consider the actuator's speed and its ability to handle varying loads. The response time of a pneumatic actuator will greatly affect the overall performance of your application, especially in automation processes where timely actuation is paramount. Additionally, reviewing installation requirements and environmental factors, such as temperature and exposure to corrosive substances, can help in selecting an actuator that will endure the specific conditions it will encounter. By meticulously assessing these performance specifications, you can ensure that the chosen pneumatic actuator aligns with the unique demands of your application, ultimately optimizing performance and longevity.

Future Trends in Pneumatic Actuator Technology for 2025

In 2025, the pneumatic actuator market is poised to experience transformative advancements driven by both technological innovation and evolving industrial needs. One of the future trends is the increased integration of smart technology into pneumatic actuators. According to a recent report by MarketsandMarkets, the global smart actuator market is projected to reach USD 8.3 billion by 2025, highlighting a growing demand for actuators that offer enhanced connectivity and control capabilities. This trend will enable real-time monitoring and performance optimization, leading to improved efficiency and reduced operational costs.

Moreover, the sustainability movement is shaping the direction of pneumatic actuator technology. Industry analysts indicate that manufacturers are focusing on developing eco-friendly materials and energy-efficient designs to comply with stringent environmental regulations. Research from Technavio reveals that the use of pneumatic actuators in applications requiring renewable energy solutions will see significant growth, particularly in wind and solar industries. This shift reflects a broader commitment among companies to reduce their carbon footprint and adopt greener practices, which is expected to influence actuator design and manufacturing processes significantly.

How to Choose the Right Pneumatic Actuator for Your Application in 2025 - Future Trends in Pneumatic Actuator Technology for 2025

| Application | Actuator Type | Size (inches) | Pressure Rating (psi) | Response Time (ms) | Energy Efficiency |

|---|---|---|---|---|---|

| Material Handling | Rotary Actuator | 2 | 80 | 50 | High |

| Automotive Assembly | Linear Actuator | 4 | 100 | 30 | Medium |

| Pharmaceutical Production | Mini Actuator | 1.5 | 50 | 20 | Very High |

| Food Processing | Slide Actuator | 3 | 75 | 40 | High |

| Chemical Processing | Double Acting Actuator | 5 | 150 | 35 | Medium |

Related Posts

-

Why Pneumatic Rotary Actuators Are Essential for Modern Automation

-

Exploring Pneumatic Rotary Actuator Innovations at 2025 China Import and Export Fair

-

Top 5 Types of Butterfly Valves You Need to Know for Optimal Performance

-

Top Pneumatic Flow Control Valve Types Explained: Choosing the Right One

-

Exploring the Future of Pneumatic Control Valves in 2025 Top Digital Innovations

-

Understanding the Role of Spring Check Valves in Modern Fluid Systems: A Comprehensive Guide