Blog

How to Choose the Right Pneumatic Valve Actuator for Your Application

Choosing the right pneumatic valve actuator is critical for workflow efficiency. Experts agree on the importance of precision. John Smith, a leading figure in the pneumatic systems industry, once stated, “Selecting the correct actuator can significantly impact system performance and reliability.”

In an ever-evolving industrial landscape, the choices you make can define success or failure. The right pneumatic valve actuator enhances operational efficiency. It’s essential to match the actuator to your specific needs. Size, compatibility, and control type all matter. Don’t overlook these details. They can make or break your system’s effectiveness.

Many overlook the complexities of their specific applications. This can lead to costly mistakes. Factors like pressure ratings and environmental conditions should inform your decision. Remember, even minor oversights have profound impacts. Reflect on your unique requirements before making a choice. The right decision today echoes in your operation’s success tomorrow.

Understanding Pneumatic Valve Actuators: Types and Their Functions

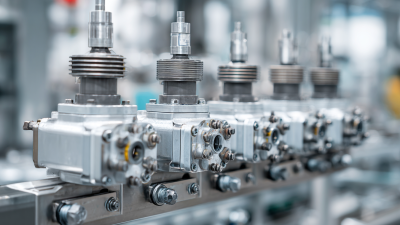

Pneumatic valve actuators are crucial in various industrial applications. They convert compressed air energy into mechanical motion. This motion controls the opening or closing of valves. Understanding their types and functions is essential for optimal performance.

There are several types of pneumatic actuators: linear and rotary. Linear actuators move valves in a straight line. They are often used in throttle and control valves. Rotary actuators are designed for quarter-turn valves. This includes ball valves and butterfly valves. According to recent industry data, linear actuators hold about 60% of the market share. However, the rotary segment is growing rapidly due to its efficiency.

Choosing the right actuator isn't straightforward. Each application has unique requirements. Factors like pressure, speed, and torque need careful consideration. Misjudging these elements may lead to system failures. For example, an actuator with insufficient torque can fail to operate the valve properly. Evaluating specifications and conducting a thorough application analysis is critical. A miscalculation can be costly, impacting productivity and safety.

Types of Pneumatic Valve Actuators and Their Applications

This chart illustrates the distribution of pneumatic valve actuators used in various industrial applications. It shows that linear actuators are the most commonly used, followed by rotary actuators, which play crucial roles in controlling the movement of valves in different environments.

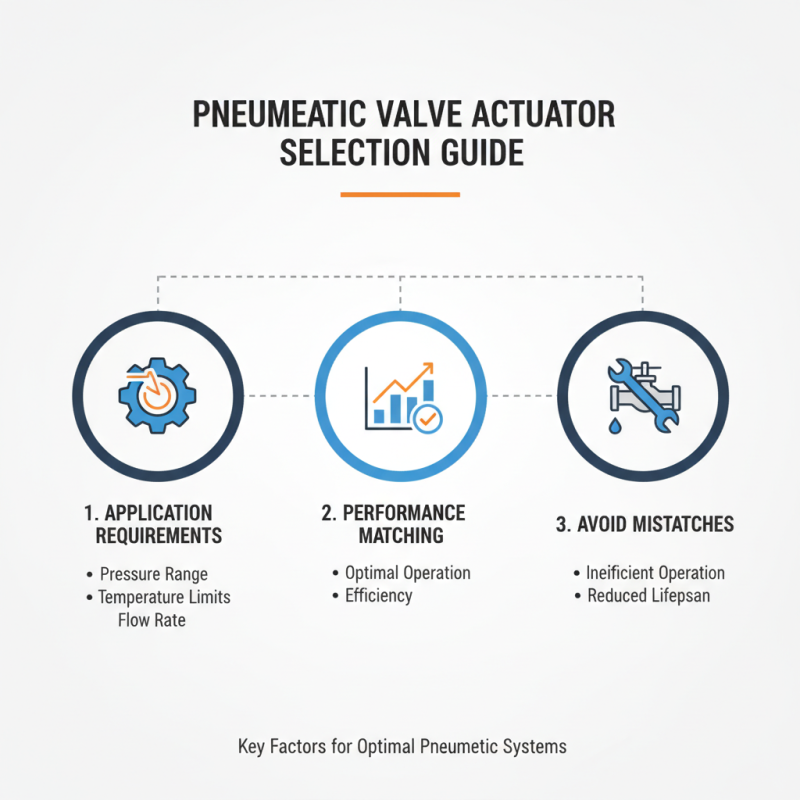

Key Factors to Consider When Selecting Pneumatic Valve Actuators

When selecting pneumatic valve actuators, several key factors warrant careful consideration. One must understand the application requirements, such as pressure, temperature, and flow rate. Each actuator must align with these parameters for optimal performance. Performance matching is critical. A mismatched actuator can lead to inefficient operations.

Tips: Determine the pressure range early. This will guide your actuator selection effectively. Remember that different actuators handle different pressure limits.

Another essential factor is the actuator's response time. Some applications may require swift actuation, while others can tolerate delays. Choosing an actuator with the appropriate speed will improve system efficiency. However, be wary: quicker isn’t always better. Too fast can cause system wear.

Tips: Test response times in your specific environment. Real-world conditions are often different from theoretical data. Always assess during implementation.

Evaluating Performance and Compatibility with Your System

Choosing the right pneumatic valve actuator begins with understanding your system. You need to evaluate the pressure range it operates in. Every application has unique pressure needs. If you select an actuator that can't handle these pressures, it will fail. Failure can lead to costly downtime and safety risks.

Compatibility is another key factor. Actuators must fit seamlessly with valves and control systems. Incorrect sizing can cause leaks or inefficient operation. Check the physical dimensions carefully. It’s common to overlook these details. Sometimes, what seems compatible isn’t. Pay close attention to connection types. This can save you from future headaches.

Performance characteristics matter too. Actuators vary in speed and responsiveness. Know the response times your application requires. A slow actuator might not meet your process needs. Test various models if possible. This hands-on approach can reveal strengths and weaknesses. Remember, no actuator is perfect. Evaluating the differences will lead to better choices.

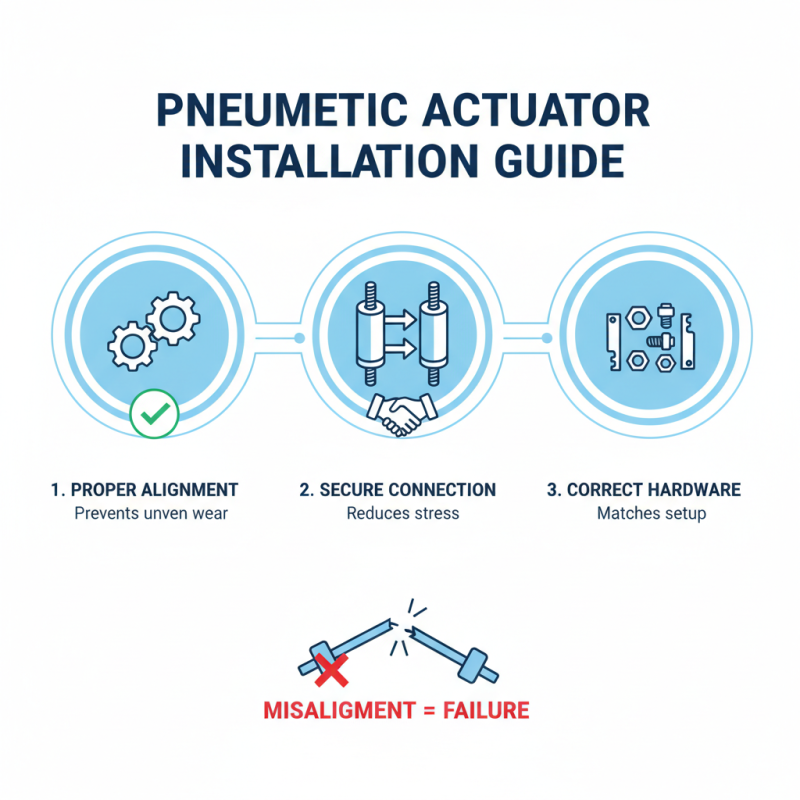

Installation and Maintenance Requirements for Pneumatic Actuators

When installing pneumatic actuators, proper alignment is crucial. Misalignment can lead to uneven wear and failure. The actuator must be connected securely to the valve. This reduces stress on both components. Use appropriate mounting hardware for your specific setup.

Maintenance is key to ensuring longevity. Regularly check air supply pressure levels. Dirty air can damage actuators over time. Inspect seals and connections for wear and tear. Small leaks can lead to inefficiencies. Address these issues promptly to avoid bigger problems later.

Despite these precautions, issues can arise unexpectedly. It’s essential to remain observant. Keep a log of maintenance activities and problems encountered. This reflective practice helps identify patterns over time. An informed approach can lead to better decision-making for future installations.

Cost Analysis and Budgeting for Pneumatic Valve Actuators

Investing in pneumatic valve actuators requires careful budgeting. The initial cost can vary widely based on type, size, and functionality. A report from a leading industry analysis firm indicates that costs can range from $500 to $5,000 per unit. This wide range reflects differences in automation capabilities and materials used. Some industries may face higher costs due to specialized designs.

When planning a budget, consider not just purchase prices but also maintenance costs. Proper maintenance can extend the lifespan of actuators and reduce downtime. Regular upkeep can cost around 10% of the actuator's price annually. An overlooked area is energy consumption; despite initial savings from low-cost options, their inefficiency may lead to higher operational costs over time.

Evaluating total cost of ownership (TCO) provides a clearer financial picture. This includes initial purchase, maintenance, and energy costs over the actuator’s life. Manufacturers often underestimate these factors. A comprehensive cost analysis can uncover hidden expenses. It is crucial to align actuator choices with operational needs, ensuring longevity and efficiency. This reflection is vital as many overlook TCO and prioritize immediate savings.

Related Posts

-

Revolutionizing Industrial Automation with Cutting-Edge Pneumatic Valve Actuators

-

Exploring Air Actuator Innovations at the 138th Canton Fair 2025 in China

-

2025 Top 5 Pneumatic Control Valves for Optimal Industrial Automation

-

Exploring the Future of Pneumatic Control Valves in 2025 Top Digital Innovations

-

10 Essential Tips for Choosing the Right Air Actuator for Your Projects

-

How to Choose the Right Pneumatic Butterfly Valve for Your Applications