Blog

How to Choose the Right Basket Strainers for Your Industrial Needs

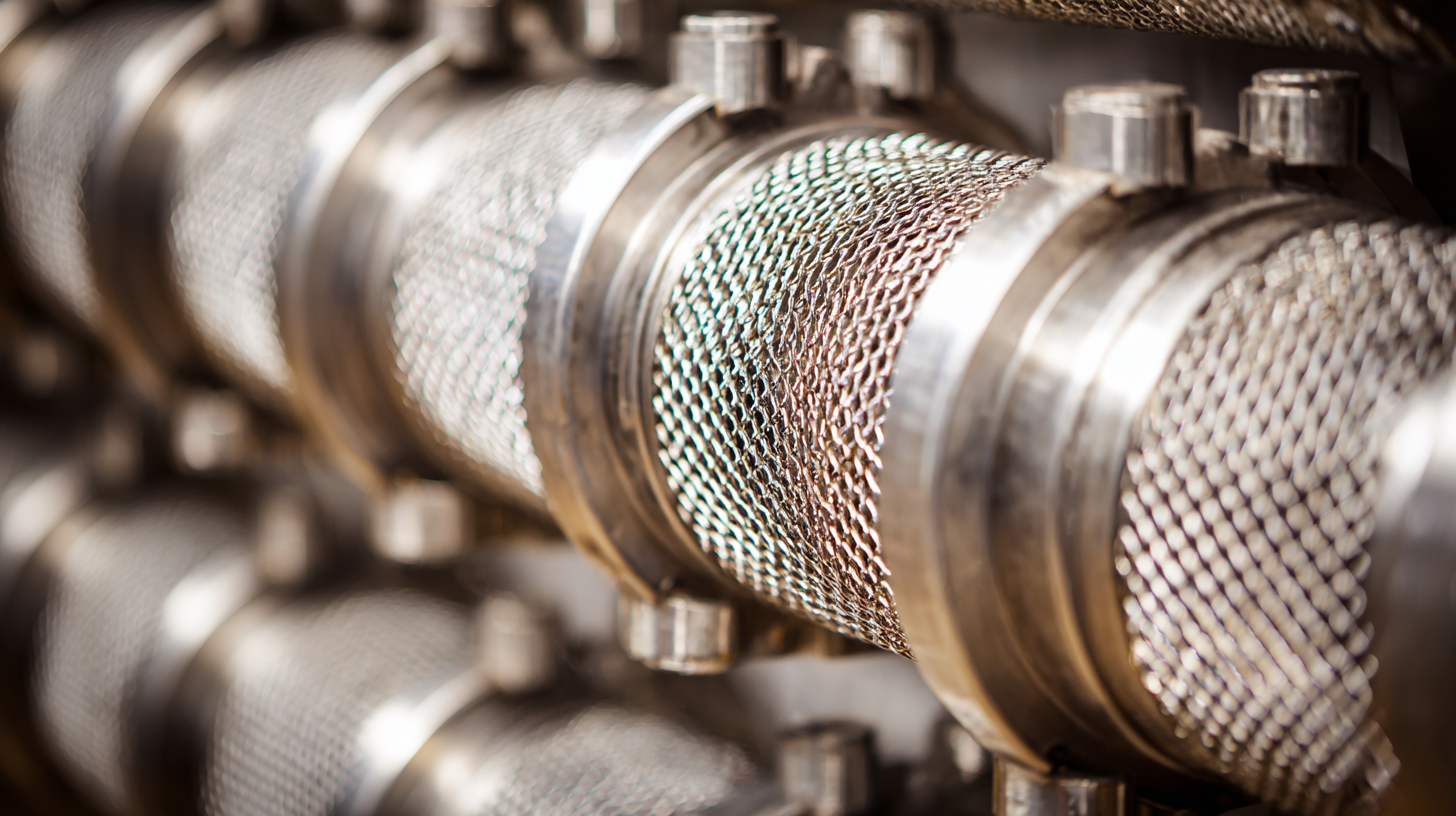

In the realm of industrial applications, the selection of the appropriate basket strainers is crucial for ensuring efficient operation and maintenance of fluid systems. According to a report by MarketsandMarkets, the global industrial filtration market is projected to reach USD 31.38 billion by 2025, emphasizing the growing importance of effective filtration solutions like basket strainers. These devices play a pivotal role in safeguarding equipment from harmful debris and sediment, ultimately enhancing operational efficiency.

With various designs and materials available, choosing the right basket strainers tailored to specific industrial needs requires an understanding of key factors such as flow rate, mesh size, and the nature of the fluids being processed. By making informed decisions, industrial operators can significantly reduce downtime and maintenance costs, while also improving overall system reliability.

Understanding the Basics of Basket Strainers: Types and Functions

Basket strainers are essential components in various industrial applications, designed to filter out debris and contaminants from liquids. Understanding the basics of these strainers is vital for selecting the right type for specific needs. There are several types of basket strainers available, including simplex and duplex models. Simplex strainers consist of a single basket, making them suitable for processes where flow can be interrupted for cleaning. In contrast, duplex strainers feature two baskets, allowing for continuous flow while one basket is cleaned or replaced.

The functions of basket strainers extend beyond mere filtration. They help protect sensitive downstream equipment, such as pumps and valves, from damage caused by foreign particles. Additionally, the choice of basket material, mesh size, and design can significantly influence the efficiency of the filtration process. Different industries may require specific configurations based on the type of fluid being processed and the nature of the impurities present. Understanding these factors is crucial in making an informed decision when choosing the right basket strainer for optimal operational efficiency.

Key Factors to Consider When Selecting Basket Strainers for Industry

When selecting basket strainers for industrial applications, several key factors must be considered to ensure efficiency and effectiveness. One critical aspect is the mesh size of the strainer. According to a report by the International Filtration Association, properly sized mesh can significantly improve filtration performance, with optimal sizes ranging from 20 to 100 microns for most industrial liquid applications. Choosing the right mesh size not only impacts the quality of filtration but also affects the flow rate, which is crucial in high-volume operations.

Another important factor is the material construction of the basket strainer. Different industries may require strains made from stainless steel or plastic, depending on the corrosive properties of the fluids being filtered. Research from the American Society of Mechanical Engineers highlights that stainless steel strainers can withstand higher temperatures and pressures, making them suitable for challenging environments. Furthermore, the ease of cleaning and maintenance is vital; strainers with removable baskets facilitate quick upkeep, minimizing downtime in production processes. Ultimately, understanding these key factors will help industries select the right basket strainers to meet their specific filtration needs.

How to Choose the Right Basket Strainers for Your Industrial Needs - Key Factors to Consider When Selecting Basket Strainers for Industry

| Strainer Type | Application | Mesh Size (Microns) | Material | Flow Rate (GPM) | Operating Pressure (psi) |

|---|---|---|---|---|---|

| Y-Strainer | Water Treatment | 100 | Stainless Steel | 400 | 150 |

| Basket Strainer | Chemical Processing | 200 | Carbon Steel | 600 | 250 |

| T-strainer | Oil and Gas | 150 | PVC | 300 | 200 |

| Dual Basket Strainer | Pharmaceutical | 50 | 316 Stainless Steel | 700 | 300 |

Material Choices: Selecting the Right Basket Strainer for Your Environment

When selecting basket strainers for industrial applications, material choice plays a crucial role in ensuring optimal performance and longevity. The environment in which the strainer will operate—such as exposure to chemicals, temperature variations, and pressure conditions—will significantly influence the appropriate material selection.

Common materials include stainless steel, carbon steel, and plastic, each offering unique benefits suited to specific applications. For instance, stainless steel is highly resistant to corrosion and is ideal for chemical processing plants, while carbon steel may be appropriate for applications that do not involve harsh chemicals but require structural strength.

Moreover, the choice of material should take into consideration the type of fluid being filtered. If the fluid contains abrasive particles, materials that can withstand wear and tear, like high-alloy stainless steel, should be prioritized. For environments prone to thermal expansion or contraction, *materials with good thermal stability* are essential. Understanding these factors will not only enhance the efficiency of the filtration system but will also reduce maintenance costs and prolong the lifespan of the basket strainers in your industrial setup. Selecting the right material ensures that the strainers perform optimally in their specific environments.

Sizing and Flow Rate: Ensuring Optimal Performance of Basket Strainers

When selecting basket strainers for industrial applications, understanding the sizing and flow rate is crucial for ensuring optimal performance. According to a report by the Industrial Fluid System Association, proper sizing of strainers can significantly enhance system efficiency, with correctly sized strainers reducing turbulence and pressure drops by up to 30%. This not only improves overall flow rates but also extends the lifespan of downstream equipment by minimizing the risk of damage caused by particulate blockage.

Flow rate is another vital aspect to consider. A survey conducted by Engineering Toolbox indicated that failing to match the flow rate of a strainer to the specifications of the piping system can lead to decreased performance and increased operational costs. For instance, a flow rate that exceeds the strainer's capacity may result in excessive maintenance, with particles bypassing the filter medium and contaminating the system. Therefore, it’s essential to calculate the optimal flow rate based on the specific requirements of your application, ensuring that you choose a basket strainer that effectively handles the anticipated load while maintaining efficiency.

Maintenance and Replacement: Keeping Your Basket Strainers Functional and Efficient

When selecting the right basket strainers for industrial applications, maintenance and replacement are critical components to ensure their functionality and efficiency. Regular inspection is essential, as strainers can experience wear and tear due to the accumulation of debris. This is particularly important in environments where liquid flow may include both micron-sized particles and larger solids. Implementing an effective maintenance schedule can not only extend the lifespan of the strainers but also prevent costly downtime associated with system failures.

Incorporating advanced technologies such as automatic self-cleaning scraper strainers can further enhance operational efficiency. Unlike traditional backwash systems, these strainers are designed to resist clogging and fouling, ensuring a consistent flow rate even in challenging conditions. Regular maintenance of these systems often involves checking the self-cleaning mechanisms and replacing components as necessary to ensure they perform optimally. By prioritizing maintenance and timely replacement, industries can achieve greater reliability and effectiveness in their filtration processes, ultimately leading to improved overall system performance.