Blog

How to Choose the Right Stainless Steel Check Valve for Your Plumbing Needs

In today's plumbing landscape, the selection of the right components is crucial for ensuring system efficiency and longevity. Among these components, the stainless steel check valve stands out as an essential fixture designed to prevent backflow and protect the integrity of plumbing systems. According to a recent report by the Plumbing Industry Association, over 30% of plumbing failures can be attributed to improper valve selection, emphasizing the need for informed decisions in the purchasing process.

Renowned industry expert Dr. Henry Watson, a leading authority in plumbing standards, emphasizes the importance of choosing quality materials in his research, stating, "A stainless steel check valve not only enhances durability but also contributes to the overall reliability of plumbing systems." With numerous options available, factors such as size, pressure rating, and application environment must be carefully considered to optimize performance.

As you navigate the myriad of choices, understanding the characteristics and benefits of stainless steel check valves can empower you to make an informed decision that aligns with your plumbing needs. This guide aims to illuminate the essential criteria and considerations necessary for selecting the perfect valve for your project.

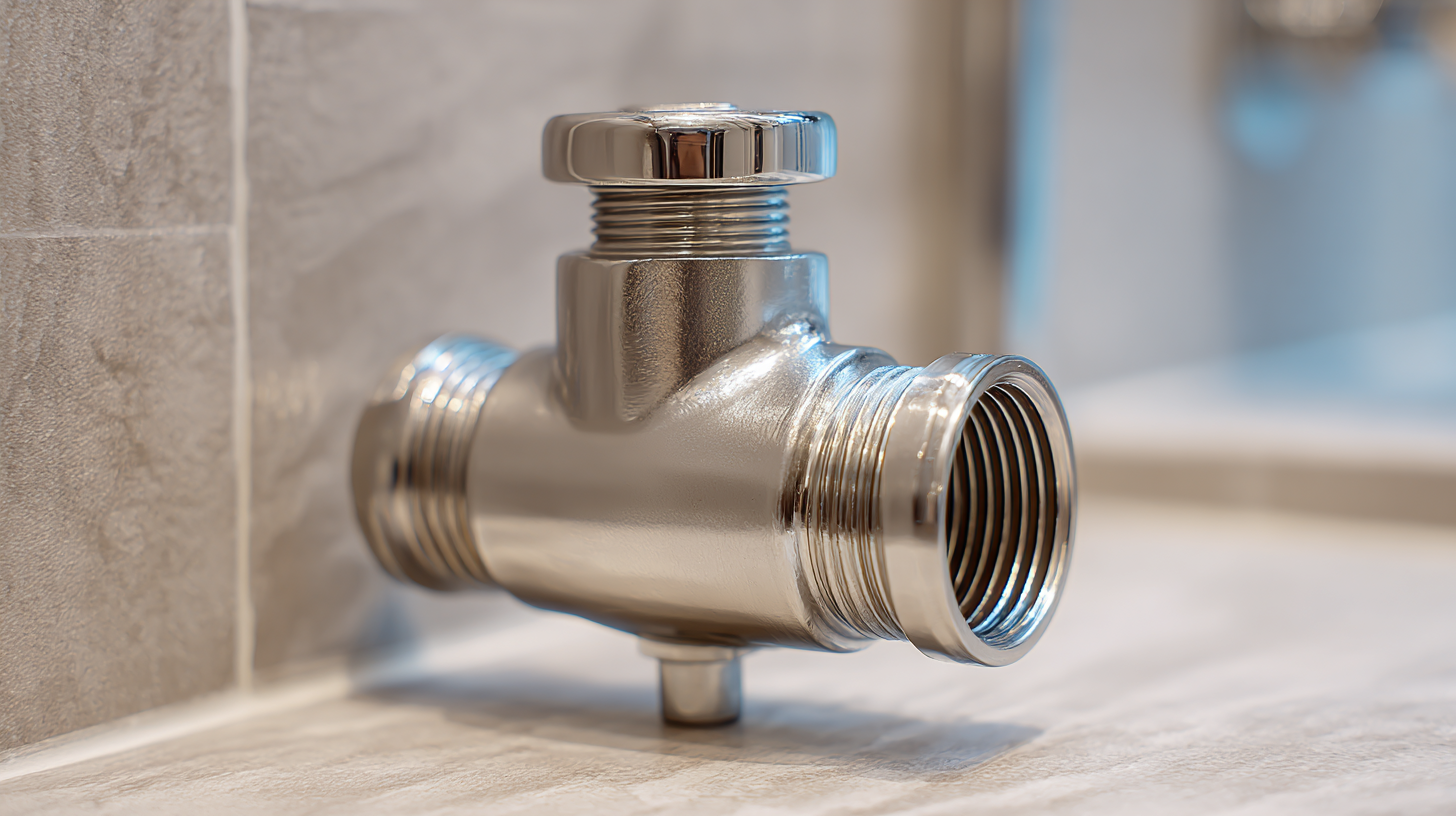

Understanding the Different Types of Stainless Steel Check Valves Available

When selecting the right stainless steel check valve for your plumbing needs, it’s crucial to understand the various types available in the market. Stainless steel check valves come in different designs such as spring-loaded, ball, and swing check valves, each serving unique operational requirements. According to a report by the Global Market Insights, the demand for stainless steel check valves is projected to grow by approximately 5% annually, highlighting their importance in both industrial and residential applications.

Tip: To ensure optimal performance, consider the pressure rating and temperature range of the valve, which should align with your plumbing system specifications. For instance, ANSI/DIN standards dictate that a suitable stainless steel check valve should withstand working pressures up to 150 PSI and temperatures ranging from -20°F to 450°F, depending on fluid characteristics.

Furthermore, selecting the correct type also depends on the flow direction and your system's hydraulic needs. Swing check valves are ideal for applications with high flow rates, while ball check valves are excellent for smaller pipelines where space is a concern. Adhering to these guidelines can significantly enhance the efficiency of your plumbing system.

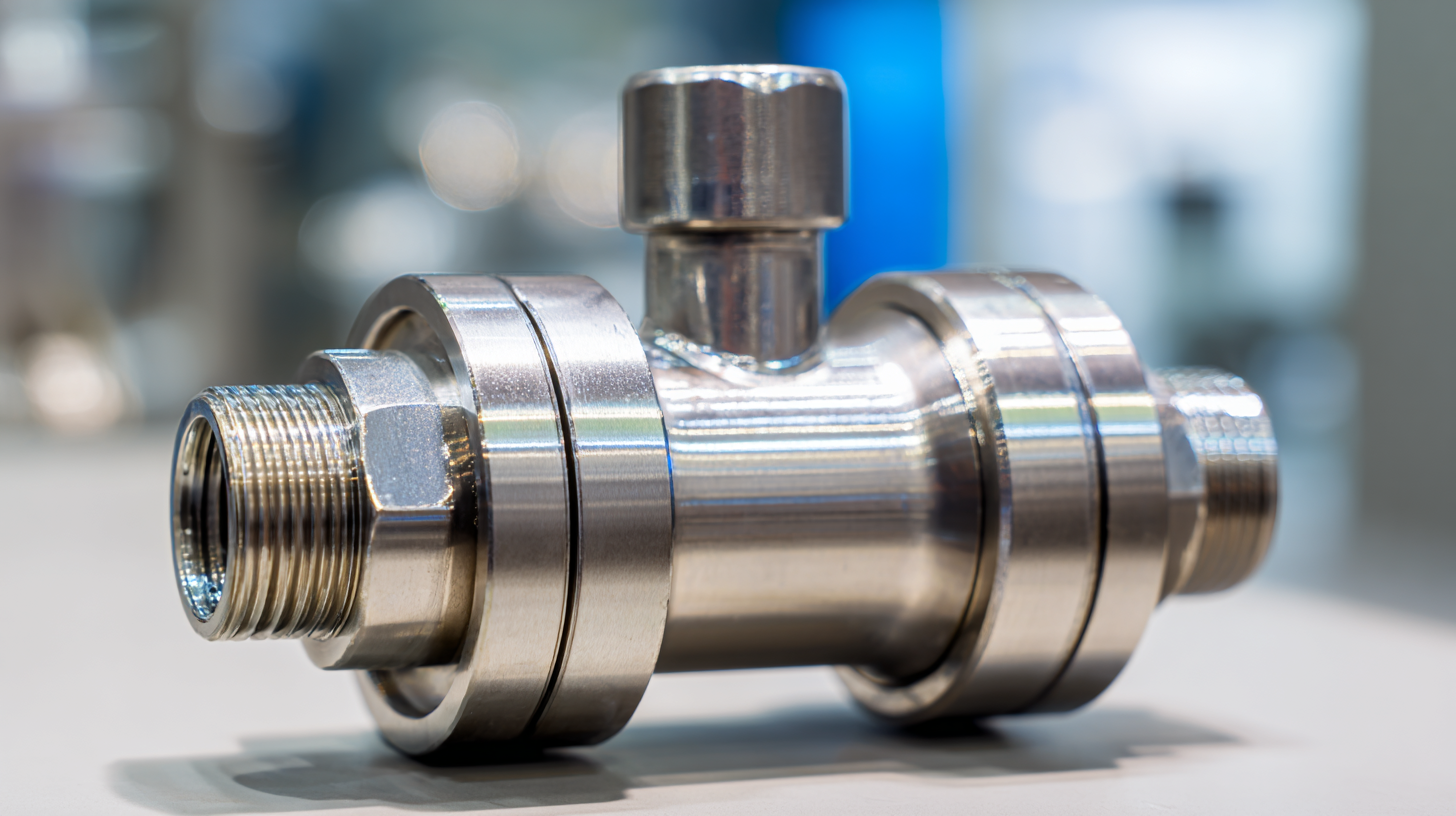

Key Factors to Consider When Selecting a Stainless Steel Check Valve

When selecting a stainless steel check valve for your plumbing needs, it is crucial to consider several key factors to ensure optimal functionality and durability. First, you should evaluate the pressure rating of the valve. Different plumbing systems operate under varying pressures, and choosing a valve that can withstand the maximum pressure of your system will prevent failures and leaks. Additionally, consider the size and diameter of the valve, as this will affect the flow rate and compatibility with your existing plumbing.

Another important factor is the type of fluid that will pass through the valve. Some stainless steel check valves are designed specifically for certain materials—whether it be water, oil, or chemicals—and selecting the appropriate type will help prevent corrosion and ensure the longevity of the valve. Finally, the installation environment plays a crucial role; consider factors such as temperature extremes and exposure to harsh conditions. Ensuring that the check valve is suitable for the specifics of your plumbing system will provide reliable performance and reduce maintenance needs over time.

Comparison of Key Factors for Selecting Stainless Steel Check Valves

This chart outlines the key factors to consider when selecting a stainless steel check valve, along with a numerical representation of their importance based on common plumbing needs. Each factor is rated on a scale of 1 to 10, indicating how crucial it is for decision-making.

Identifying the Right Size and Pressure Rating for Your Plumbing System

When selecting the appropriate stainless steel check valve for your plumbing system, understanding the right size and pressure rating is crucial. The size of the valve must match the diameter of the pipes in your plumbing system to ensure optimal flow and prevent any bottlenecks. A properly sized valve will facilitate efficient water movement without causing excess pressure drop, which can lead to wear and tear over time.

In addition to size, the pressure rating of the check valve must align with the specifications of your plumbing system. Check valves are available in various pressure ratings, and choosing one that can handle the maximum pressure within your system is essential to prevent valve failure. It’s important to consider the operational conditions, such as temperature fluctuations and the type of fluids being transported. By carefully matching both the size and pressure rating of the valve to your plumbing requirements, you can ensure reliable performance and longevity of the system.

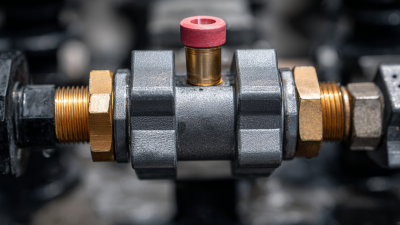

Comparing the Costs and Lifespan of Various Stainless Steel Check Valve Options

When selecting a stainless steel check valve for your plumbing system, understanding the costs and lifespan of different options is crucial. Stainless steel check valves can vary significantly in price, with factors that include the valve type, material grade, and manufacturing process. Higher-quality grades, such as 316 stainless steel, typically offer better resistance to corrosion and higher temperatures, which can justify a higher initial investment. Conversely, lower-grade options may be more cost-effective but might lead to premature failures in harsh environments.

Tips for choosing the right check valve include assessing the specific requirements of your plumbing application. For instance, consider the fluid type, temperature, and pressure to ensure compatibility with a specific valve. Additionally, investing in valves from reputable manufacturers can lead to improved durability, helping you avoid frequent replacements that ultimately raise long-term costs.

When evaluating lifespan, it’s vital to recognize that proper installation and maintenance significantly affect performance. Regular inspections can help identify wear and tear before it leads to significant issues. Look for models that offer warranties or endorsements that speak to their longevity, providing you assurance on your investment as you make an informed choice for your plumbing needs.

How to Choose the Right Stainless Steel Check Valve for Your Plumbing Needs

| Type | Cost Range (USD) | Lifespan (Years) | Common Applications |

|---|---|---|---|

| Swing Check Valve | $50 - $200 | 10 - 15 | Water and wastewater systems |

| Lift Check Valve | $80 - $250 | 8 - 12 | Pumping and drainage systems |

| Ball Check Valve | $40 - $160 | 5 - 10 | Low-pressure applications |

| Duckbill Check Valve | $30 - $120 | 5 - 7 | Sewer and drainage applications |

| Wafer Check Valve | $25 - $100 | 10 - 20 | HVAC, water, and gas systems |

Maintenance Tips for Ensuring Optimal Performance of Your Check Valve

To maintain optimal performance of your stainless steel check valve, regular maintenance is crucial. According to the Valve Manufacturers Association, improper maintenance leads to over 30% of valve failures in industrial applications. Regular inspections should include checking for leaks, corrosion, and wear, particularly at the seals and seating surfaces.

Additionally, it’s important to ensure that the check valve is installed correctly. Misalignment can cause significant damage and reduce the efficiency of your plumbing system. The American Society of Mechanical Engineers reports that proper alignment can extend the lifespan of check valves by up to 20%.

Tips: Use pipe supports to maintain alignment and reduce stress on the valve during installation. Always refer to the manufacturer's guidelines for installation practices.

Finally, consider the environment your check valve operates in. Stainless steel is resistant to corrosion, but exposure to harsh chemicals can still lead to degradation. Regularly assess the chemicals your plumbing system encounters and adjust your maintenance schedule accordingly.

Tips: If your check valve is exposed to chemically aggressive conditions, increase the frequency of inspections to every three months.

Related Posts

-

Understanding the Role of Spring Check Valves in Modern Fluid Systems: A Comprehensive Guide

-

Understanding the Importance of Spring Check Valve in Modern Plumbing Systems

-

Exploring Pneumatic Rotary Actuator Innovations at 2025 China Import and Export Fair

-

How to Choose the Right Pneumatic Valve for Your Industrial Application

-

Understanding the Benefits of Butterfly Valves in Modern Industrial Applications

-

Unlocking Automation: The Future of Electric Actuators in Smart Technology