Blog

How to Choose the Right Knife Gate Valve for Your Industrial Application

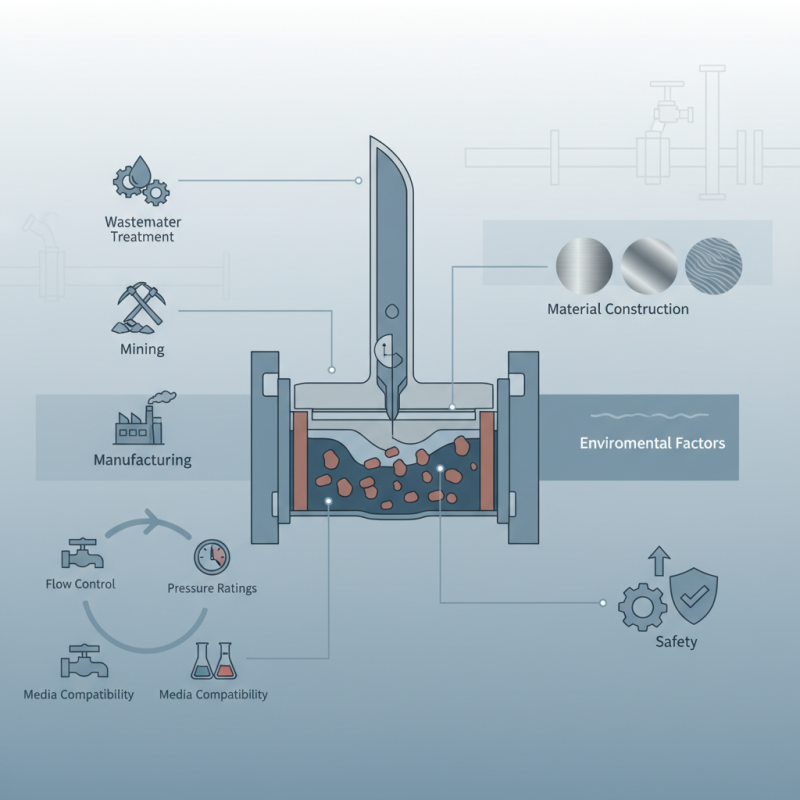

When it comes to industrial processes, the choice of valves is crucial for ensuring efficient and reliable operations. Among the various types of valves, the knife gate valve stands out for its unique design and functionality, particularly in applications where handling viscous fluids or solids is a necessity. This distinctive valve type is engineered to provide a tight seal in high-pressure environments, making it a preferred choice in industries such as wastewater treatment, mining, and manufacturing.

Understanding the specific requirements of your application is key to selecting the right knife gate valve. Different operational challenges, such as flow control, pressure ratings, and compatibility with various media, must be carefully considered. Additionally, factors such as the valve's material construction and the nature of the environment in which it will be used can significantly influence performance and longevity. By taking these aspects into account, engineers and decision-makers can ensure they select a knife gate valve that not only meets operational demands but also enhances the overall efficiency and safety of their industrial systems.

How Knife Gate Valves Function in Industrial Applications

Knife gate valves are essential components in many industrial applications, particularly in systems handling slurries, solids, and liquids. Unlike traditional valves, knife gate valves are designed with a sharp-edged blade that effectively cuts through slurries and other viscous materials, which allows for efficient isolation and control of flow. According to a report from the Market Research Future, the global knife gate valve market is expected to grow at a compound annual growth rate (CAGR) of over 5% from 2021 to 2026, indicating their increasing importance in various industries.

The functionality of knife gate valves in industrial settings is largely determined by their design features, such as the blade geometry and seal arrangement. These valves are engineered to provide low-pressure drop and high flow efficiency, making them particularly effective in bulk material handling applications like wastewater treatment and mining. Industry standards, such as those set by the American National Standards Institute (ANSI), emphasize the importance of robust construction to withstand harsh operational environments. Data also shows that proper installation and maintenance of knife gate valves can lead to a significant reduction in operational downtime, often cited at up to 20% in some industries.

How to Choose the Right Knife Gate Valve for Your Industrial Application

| Valve Type | Material | Size | Pressure Rating (psi) | Temperature Rating (°F) | Application |

|---|---|---|---|---|---|

| Manual Knife Gate Valve | Cast Iron | 4 inches | 150 psi | -20 to 150°F | Slurry Applications |

| Electric Knife Gate Valve | Stainless Steel | 6 inches | 300 psi | -20 to 200°F | Chemical Processing |

| Pneumatic Knife Gate Valve | PVC | 8 inches | 100 psi | 0 to 140°F | Water Treatment |

| Automated Knife Gate Valve | Carbon Steel | 10 inches | 250 psi | -20 to 250°F | Mining & Aggregates |

Key Factors to Consider When Selecting Knife Gate Valves

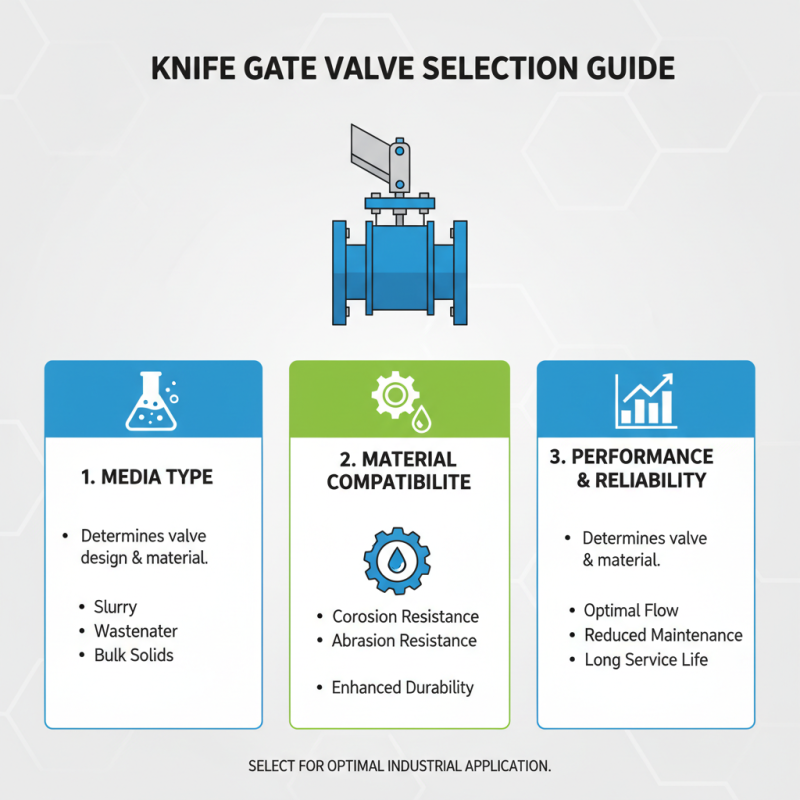

When selecting a knife gate valve for your industrial application, several key factors must be considered to ensure optimal performance and reliability. First and foremost, the type of media being handled, whether it’s slurry, wastewater, or bulk solids, greatly influences the design and material of the valve. Valves must be constructed from compatible materials that can withstand the corrosive or abrasive nature of the media, which leads to enhanced durability and reduced maintenance.

Another critical aspect is the valve size and end connections. The size should match the piping system to ensure proper flow and pressure control. Additionally, the type of actuation—manual, pneumatic, or electric—should align with the operational needs of the facility. It is essential to consider the installation space and whether the valve will fit comfortably within the existing infrastructure. By taking these factors into account, industries can select the right knife gate valve that not only meets operational demands but also enhances overall efficiency and safety in their processes.

Material Selection for Knife Gate Valves: Impact on Performance and Longevity

When selecting a knife gate valve for industrial applications, material choice is crucial to ensure optimal performance and longevity. The materials used in the construction of knife gate valves must withstand the specific conditions of their operational environments, including pressure, temperature, and the type of media being handled. Common materials include stainless steel, cast iron, and various plastics, each offering unique properties suitable for different applications. For instance, stainless steel provides excellent corrosion resistance and durability, making it ideal for abrasive and corrosive materials, while cast iron is often preferred for its cost-effectiveness in less demanding environments.

Tips: When deciding on the valve material, consider the chemical compatibility with the media handled. Always refer to a compatibility chart to avoid unexpected damage or failures.

Another critical factor influencing the choice of material is the potential for wear and tear over time. Abrasive materials can significantly shorten the lifespan of a valve if not paired with suitable materials. Utilizing harder materials or specifically designed coatings can enhance performance and durability, reducing maintenance costs and downtime. Additionally, the temperature range of the application should be a primary consideration, as certain materials can lose functionality outside their recommended temperature limits.

Tips: Regularly assess the operating environment and adjust your material selection as needed. This proactive approach can prevent premature valve degradation and ensure consistent performance throughout its lifespan.

Material Selection Impact on Knife Gate Valve Performance

Performance Standards and Testing Methods for Knife Gate Valves

When selecting a knife gate valve for industrial applications, understanding performance standards and testing methods is crucial. Knife gate valves are often subjected to harsh operating conditions, which makes rigorous performance evaluations essential. These evaluations typically adhere to international standards such as the American Society for Testing and Materials (ASTM) and the American National Standards Institute (ANSI). Compliance with these standards ensures that the valve can withstand specific pressures, temperatures, and flow rates, providing reliable service over time.

Testing methods for knife gate valves include hydrostatic tests, which assess the valve's ability to contain pressure without leaks, and operational tests that verify the functionality of the valve mechanism. Additional evaluations involve checking the alignment and seating of the blade, which is critical for achieving a reliable seal.

Performance metrics such as flow capacity, thermal expansion resistance, and wear under various operating conditions should also be assessed to ensure the valve meets the operational demands of the intended application. By focusing on these performance standards and testing methodologies, industries can confidently select knife gate valves that will operate effectively and last through demanding processes.

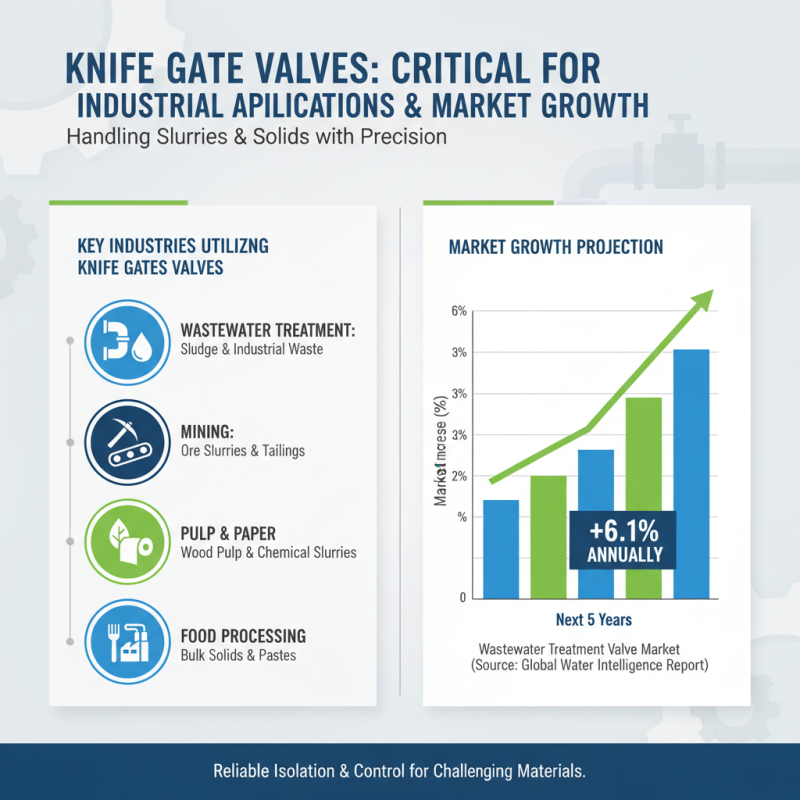

Common Industries and Applications Utilizing Knife Gate Valves

Knife gate valves are critical components in various industrial applications due to their ability to handle slurries and solids, providing effective isolation and control. Common industries utilizing knife gate valves include wastewater treatment, mining, pulp and paper, and food processing. For instance, the wastewater treatment industry, according to a report by the Global Water Intelligence, is projected to experience substantial growth, with an estimated market increase of 6.1% annually over the next five years. This rapid growth underscores the increasing demand for reliable valve solutions that can manage challenging materials like sludge and industrial waste.

In the mining industry, knife gate valves are essential for controlling the flow of materials that can be abrasive and corrosive. Industry studies indicate that proper valve selection can improve operational efficiency by up to 20%. The pulp and paper sector also benefits from knife gate valves, as they enable smooth control of fibrous materials and can withstand high pressures. In many cases, their design allows for easy maintenance and operation, which is crucial in fast-paced production environments.

Tips: When choosing a knife gate valve, consider the material compatibility with the process media, as well as the valve size and pressure rating. It’s also vital to evaluate maintenance requirements to ensure minimal downtime. Always consult product specifications and industry reports to make informed decisions tailored to your specific application needs.

Related Posts

-

Maximizing Operational Efficiency: The Role of Knife Gate Valves in Modern Industrial Applications

-

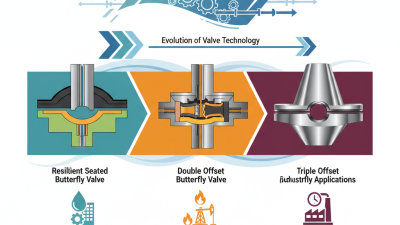

Understanding the Benefits of Butterfly Valves in Modern Industrial Applications

-

Top 5 Types of Butterfly Valves You Need to Know for Optimal Performance

-

Understanding Different Butterfly Valve Types and Their Applications

-

Exploring Air Actuator Innovations at the 138th Canton Fair 2025 in China

-

Understanding Motorized Valves: Essential Components for Efficient Fluid Control Systems