Blog

How to Choose the Right Pneumatic Actuator for Your Needs?

In the world of industrial automation, selecting the right pneumatic actuator is crucial. Industry reports indicate that pneumatic actuators account for around 25% of the global actuator market. Their efficiency and adaptability make them a preferred choice in various applications. However, choosing the right one involves many considerations, often leading to confusion.

Expert Justin Crowley, a leading figure in actuator technology, once stated, “The right pneumatic actuator can significantly enhance operational efficiency.” Understanding the specifics of your application, including pressure requirements, speed, and load capacity, is essential. Many users overlook these factors, which can lead to performance setbacks.

According to recent studies, about 30% of pneumatic actuators fail to meet operational demands. This highlights the importance of thorough research and analysis. Users often need to reflect on their choices. Selecting the correct pneumatic actuator is not just about specifications; it is also about aligning with application needs. The right decision can drive productivity and reduce costs in a long-term perspective.

Understanding Pneumatic Actuators: Types and Specifications

Pneumatic actuators play a crucial role in various industrial applications. They convert compressed air energy into mechanical motion. Understanding the types and specifications is vital for optimizing performance. Major types include diaphragm, piston, and rotary actuators. Each type has distinct features and best-use scenarios.

Diaphragm actuators offer quick response times. They are often used in process control. Piston actuators, however, are known for their high force output. Data shows that they can generate forces exceeding 2,000 pounds in some cases. Rotary actuators are compact. They provide precise motion for limited spaces. The choices depend on specific needs.

Evaluating specifications is equally important. Factors like pressure ratings and cycle times impact efficiency. For example, a high cycle rate may indicate wear over time. Research suggests that improperly selected actuators can lead to a 30% increase in operational costs. Ensuring compatibility with existing systems is crucial. Monitoring performance consistently helps in identifying potential issues before they escalate.

Types of Pneumatic Actuators and Their Applications

Evaluating Performance Metrics: Torque, Speed, and Pressure Requirements

Selecting the right pneumatic actuator requires careful evaluation of performance metrics. Torque, speed, and pressure requirements directly impact the actuator's effectiveness. Torque is essential to ensure that the actuator can handle the load it needs to move. A higher torque rating means the actuator can handle larger or more resistant loads. However, too much torque can lead to inefficiencies or potential damage. It is vital to strike a balance.

[Image] Speed is another critical factor. It determines how quickly the actuator can perform its task. A faster actuator improves operational efficiency but may compromise control accuracy. It's crucial to assess whether speed aligns with the needs of a specific application. Sometimes, a slower but more controlled movement is better than hastily completing a task.

Pressure requirements must also be considered. Different applications require varying pressure levels. Too low pressure may not actuate properly, while too high could damage components. Evaluate the environment where the actuator will operate, as external factors can influence performance. It's not always a straightforward decision. Each variable requires reflection and adjustment based on the specific needs of the application. Taking the time to analyze these metrics can prevent future complications and enhance overall efficacy.

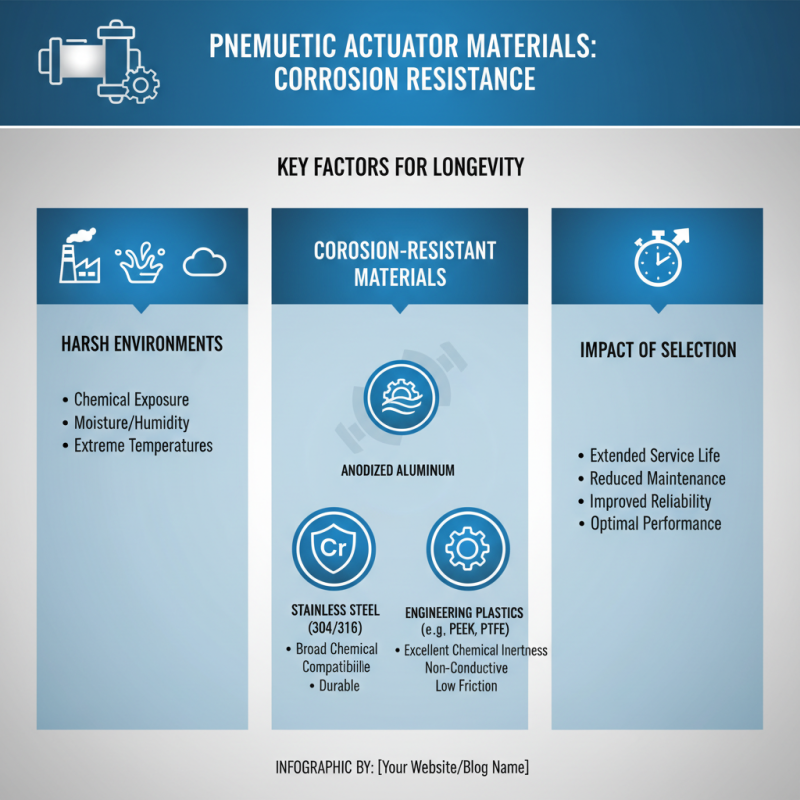

Selecting Materials: Corrosion Resistance and Operating Environment Considerations

Choosing the right materials for pneumatic actuators is crucial. Corrosion resistance is a key factor. Actuators are often exposed to harsh environments. Selecting materials that withstand corrosive agents is essential for longevity.

A report by the International Society for Corrosion suggests that nearly 30% of actuator failures stem from corrosion. This statistic highlights the importance of choosing appropriate materials. Stainless steel is a common choice for its excellent corrosion resistance. However, it may not always be the best option for every environment. In some cases, carbon steel with protective coatings can perform just as well.

The operating environment also plays a significant role. High humidity or exposure to chemicals can degrade materials quickly. For instance, actuators used in marine applications face saltwater corrosion. In such scenarios, specialized coatings or even titanium might be necessary. Material selection is not always straightforward and can be challenging. Balancing cost with durability often requires careful evaluation of the specifics.

Assessing Control Systems Compatibility: Analog vs. Digital Interfaces

When selecting a pneumatic actuator, assessing control systems compatibility is crucial. Analog and digital interfaces each offer distinct advantages. Analog systems provide simplicity and ease of integration. Their continuous signal allows for smooth control, which is ideal for many industrial applications. However, they can be prone to noise, leading to less precise control.

On the other hand, digital interfaces bring advanced functionality. They offer greater precision and better data handling. Modern reports indicate that about 70% of new installations prefer digital control due to its scalability. This allows for better performance monitoring and remote adjustments. However, not all existing systems are ready for digital upgrades, which can complicate integration. Understanding these differences can prevent costly oversights when choosing an actuator.

It's essential to evaluate the specific needs of an application. In certain industries, outdated analog systems may still perform adequately. Yet, shifting towards digital might enhance long-term efficiency and data analytics. Recognizing these factors is vital for optimal actuator selection.

Choosing the Right Pneumatic Actuator: Assessing Control Systems Compatibility

| Parameter | Analog Interface | Digital Interface |

|---|---|---|

| Signal Type | Continuous Voltage/Current | Discrete Digital Signals |

| Response Time | Slightly Slower | Faster Response |

| Complexity | Simple Integration | Requires Programming |

| Cost | Generally Lower | Generally Higher |

| Maintenance | Less Frequent Calibration | Periodic Software Updates |

| Applications | Basic Control Tasks | Complex Automation Systems |

Cost Analysis: Budgeting for Purchase, Maintenance, and Lifecycle Expenses

When budgeting for a pneumatic actuator, consider various expenses. The initial purchase price is just one part. Installation costs can vary widely based on complexity. Don’t overlook the potential need for custom fittings or additional assembly labor. These factors can significantly increase upfront costs.

Maintenance is another key aspect. Regular checks are essential for the longevity of your actuator. Count on periodic inspections and possible repairs. Spare parts might also be necessary over time. Budgeting for these unforeseen expenses is critical. It's easy to underestimate how these costs add up.

Finally, think about lifecycle expenses. A cheaper actuator may seem appealing, but it might lead to frequent issues. Reliability often comes at a price. Assess the total cost over the operational life. Long-term savings could outweigh initial savings. Reflect on these details to avoid costly mistakes.

Related Posts

-

10 Essential Tips for Choosing the Right Air Actuator for Your Projects

-

Unlocking Precision: How Hydraulic Rotary Actuators Revolutionize Industrial Automation

-

How to Select the Best Butterfly Valve Type for Your Industrial Needs

-

Exploring the Future of Basket Strainers at the 138th Canton Fair 2025 in China

-

Understanding the Role of Spring Check Valves in Modern Fluid Systems: A Comprehensive Guide

-

Understanding Motorized Valves: Essential Components for Efficient Fluid Control Systems