Blog

How to Choose the Right Spring Check Valve for Your Application?

Choosing the right spring check valve is crucial for ensuring efficiency in fluid handling systems. According to John Smith, a renowned expert in valve technology, "Selecting the correct spring check valve can mean the difference between success and failure in your project." A spring check valve prevents backflow and allows for smooth operation, but the wrong choice can lead to leaks or pressure issues.

In various applications, spring check valves come in different sizes and materials. The right one depends on factors like flow rate and pressure requirements. For example, a smaller valve may suffice in low-pressure systems. However, it might not hold up under demanding conditions. This complexity can lead to mistakes if not addressed.

It's essential to reflect on the specific needs of your project. Each choice carries weight; a simple error can lead to significant complications. Therefore, understanding your application is key. The right spring check valve must match the demands of your system to avoid future headaches.

Understanding the Functionality of Spring Check Valves

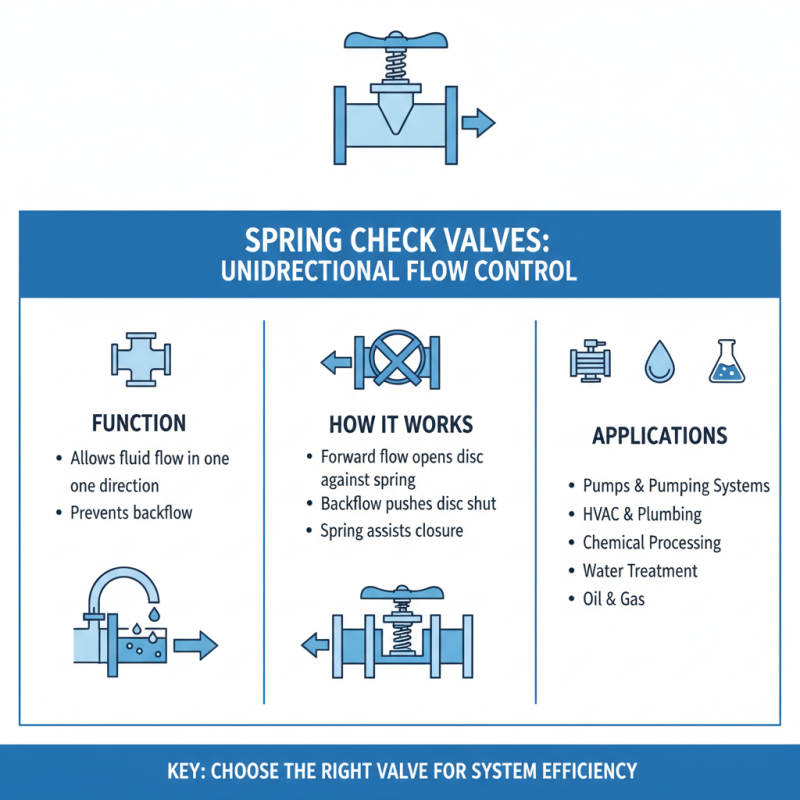

Spring check valves play a vital role in various applications. They allow fluid to flow in one direction while preventing backflow. Understanding their functionality is key to choosing the right valve for your system.

These valves operate using a spring mechanism. When fluid flows forward, the valve opens. If the flow reverses, the spring closes the valve. This simple yet effective design helps maintain system pressure and prevents water hammer, which can damage pipes. According to industry reports, improper valve selection can lead to costly maintenance. It’s crucial to assess your specific application needs.

Tips: Evaluate the fluid characteristics. Is it clean or abrasive? Also, consider pressure ratings. A mismatch can lead to failures. Always consult technical specifications to avoid mistakes.

Spring check valves come in various materials and designs. Common options include brass, stainless steel, and plastic. Each material has its pros and cons. For instance, plastic may be cheaper but might not withstand high temperatures. Review your requirements carefully. Don't overlook potential risks. Choosing the wrong type could result in leaks or inefficiencies. Always ensure compatibility with your system’s parameters to maximize efficiency and safety.

Key Factors to Consider for Selecting a Spring Check Valve

Choosing the right spring check valve requires careful consideration of several factors. Firstly, understanding the application is crucial. Different applications have unique requirements, such as pressure ratings, temperature ranges, and fluid types. According to a recent industry report, nearly 30% of valve failures can be traced back to incorrect specifications. This highlights the importance of precise selection.

Another key factor is flow characteristics. Spring check valves must handle the specific flow rates of the system. For example, a valve designed for high flow might not function effectively in low flow conditions. Statistics show that efficiency drops by 15% in mismatched flow scenarios. Additionally, consider the materials used in the valve. Corrosive fluids demand materials resistant to degradation. A failure in material selection can lead to significant downtime and increased maintenance costs.

Sizing is also significant. The valve must fit well within the existing infrastructure. A tight fit ensures better performance and longevity. Surprisingly, many projects overlook this aspect. This often results in leaks and performance issues. Reviewing the pressure drop across the valve is essential as well. An optimal pressure drop can enhance efficiency by up to 20%, according to industry studies. These factors collectively influence the effectiveness of the spring check valve chosen.

How to Choose the Right Spring Check Valve for Your Application?

| Key Factor | Description |

|---|---|

| Material | Select materials that are compatible with your medium (e.g., stainless steel for corrosive fluids). |

| Pressure Rating | Ensure the valve can handle the maximum pressure in your application. |

| Flow Rate | Choose a valve that can accommodate the required flow rate for efficiency. |

| Temperature Range | Consider the operating temperature and select a valve rated for those conditions. |

| Size | Match the valve size to the piping to ensure optimal performance and minimize pressure drops. |

| End Connection | Verify compatibility with existing pipe fittings (e.g., threaded, flanged, or welded). |

| Spring Type | Choose between different spring types depending on the specific application needs. |

| Regulatory Compliance | Ensure the valve meets relevant industry standards and regulations for safety and performance. |

Material Options for Spring Check Valves and Their Applications

Choosing the right spring check valve often hinges on the material used. Different materials serve various functions. For instance, stainless steel is popular in high-pressure applications. It resists corrosion and enhances durability. This makes it ideal for industries like oil and gas.

On the other hand, plastic valves are lightweight and cost-effective. They work well in low-pressure and non-corrosive environments. However, they may not handle extreme temperatures as effectively. Users should consider the operating conditions carefully. The wrong choice could lead to premature failure.

Bronze and brass provide excellent strength and corrosion resistance. They suit a variety of applications, from water systems to chemical processes. However, they can be more costly than other options. This cost factor is an essential consideration for budget-sensitive projects.

Each material has trade-offs that must be evaluated before making a decision.

Sizing and Pressure Ratings for Optimal Performance

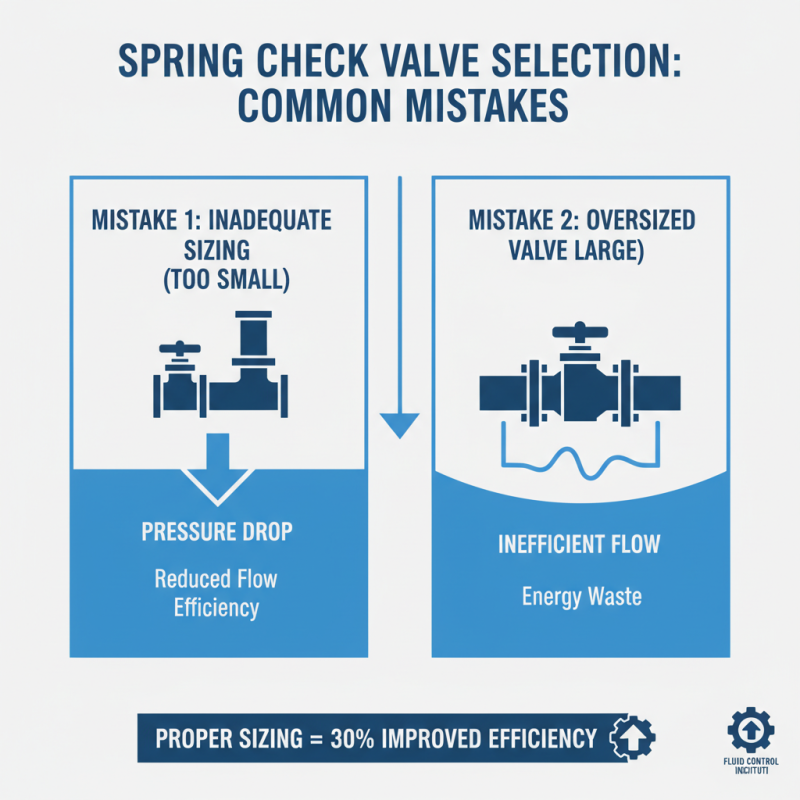

Choosing the right spring check valve for your application involves careful consideration of sizing and pressure ratings. These factors are crucial for optimal valve performance. A correctly sized valve ensures efficient fluid flow while preventing backflow. It's essential to match the valve size with the pipe diameter. An oversized valve may lead to turbulence; an undersized one could cause pressure drops.

Pressure ratings must align with your system's requirements. Examine the maximum pressure and temperature conditions for your application. Using a valve rated for these conditions will help avoid premature failure. Keep in mind that frequent cycles may require valves with higher durability.

**Tips:** Always consult application details before making purchases. Consider the material of the valve, as it affects longevity. Conduct periodic checks to ensure your valves are functioning optimally. Ignoring these aspects may lead to larger issues down the line. If unsure, it's wise to seek expert advice.

Spring Check Valve Sizing and Pressure Ratings

This chart provides a visual comparison of maximum pressure ratings for various sizes of spring check valves. Selecting the appropriate size and pressure rating is crucial for optimal performance in different applications.

Common Mistakes to Avoid When Choosing Spring Check Valves

When selecting spring check valves, common mistakes can lead to operational issues. One frequent error is inadequate sizing. A valve that is too small may cause pressure drops. Conversely, an oversized valve could lead to inefficient flow. A study by the Fluid Control Institute indicates that proper valve sizing can improve efficiency by up to 30%.

Ignoring the media characteristics is another pitfall. Different liquids or gases can corrode materials differently. For instance, aggressive chemicals can damage rubber seals in some valves. According to a report from the American Society of Mechanical Engineers, over 25% of valve failures stem from inappropriate material selection.

Another mistake is overlooking installation requirements. Incorrect installation can negate the valve's benefits. Ensuring proper orientation and spacing is crucial. A detailed analysis done by industry experts showed that 40% of spring check valve failures arise from installation errors. It’s essential to review installation guidelines closely. This helps avoid costly downtime and repairs.

Related Posts

-

Understanding the Importance of Spring Check Valve in Modern Plumbing Systems

-

Understanding the Role of Spring Check Valves in Modern Fluid Systems: A Comprehensive Guide

-

How to Choose the Right Stainless Steel Check Valve for Your Plumbing Needs

-

2025 Top 5 Motorized Valves: Best Picks for Efficiency and Performance

-

How to Choose the Right Pneumatic Valve Actuator for Your Application

-

Exploring Pneumatic Rotary Actuator Innovations at 2025 China Import and Export Fair