Blog

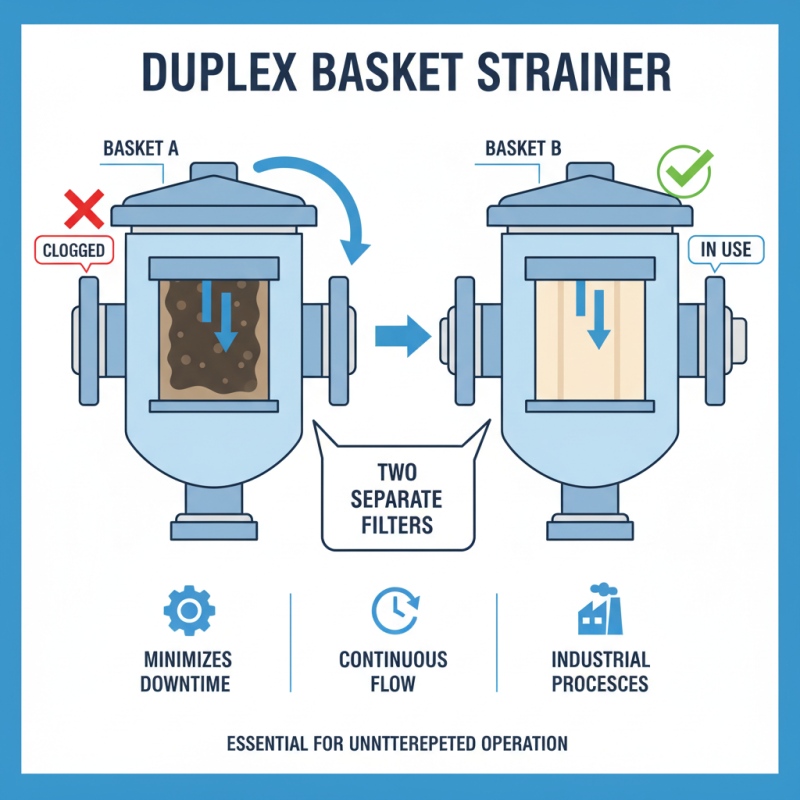

What is a Duplex Basket Strainer and How Does It Work?

In various industrial settings, the efficiency of fluid systems is paramount. A duplex basket strainer plays a critical role in maintaining this efficiency. This device operates by filtering out unwanted debris, ensuring that systems run smoothly. According to a report by the Fluid Management Association, improper filtration can lead to a 20% decrease in system efficiency over time.

Renowned filtration expert Dr. Emily Hart states, "The effectiveness of a duplex basket strainer is crucial for operational success." This underscores the importance of selecting the right strainer for specific applications. The duplex design allows for continuous operation, as one basket can be cleaned while the other remains in service.

Despite their advantages, duplex basket strainers are often overlooked. Many industries still rely on outdated methods, risking contamination and costly downtimes. Users must evaluate strainers based on their unique needs and operational contexts. Understanding the mechanics of a duplex basket strainer can lead to better decision-making and improved reliability in fluid handling processes.

What is a Duplex Basket Strainer?

A duplex basket strainer is a crucial component in various industries. It effectively filters out debris and contaminants from liquids flowing through pipelines. This type of strainer features two baskets and allows continuous operation. While one basket collects debris, the other remains in service. This ensures minimal downtime, which is vital for many processes.

Duplex basket strainers typically handle a flow rate of 100 to 5,000 gallons per minute, depending on the specific application. These units are common in wastewater treatment and chemical processing. Efficiency is essential; studies show that improper filtration can lead to increased equipment wear and system failures. It suggests the need for regular maintenance and monitoring.

Tips: Regularly inspect your duplex basket strainer. Look for clogs that might impair flow. Schedule periodic cleaning to improve efficiency. Remember, neglected strainers can increase operational costs and reduce equipment lifespan. Choose a location for easy access to make maintenance simpler. A well-maintained strainer can save time and resources in the long run.

The Components of a Duplex Basket Strainer

A duplex basket strainer is designed for filtering liquids in various applications. Its components work together to provide effective filtration. The primary components include two filter baskets, a valve system, and a housing unit.

Each basket serves as a filter. When one basket is in use, the other remains on standby. This allows for continuous operation, reducing downtime for maintenance. The housing unit contains these baskets securely. It is usually made from durable materials to withstand pressure and corrosion. The valve system is crucial; it controls the flow between the baskets. It ensures that when one basket is cleaned or replaced, the flow is diverted seamlessly to the other.

The design allows for easy access. However, improper installation can lead to leaks. Regular checks are necessary to maintain efficiency. Not all setups are perfect; some might require adjustments to optimize functionality. Understanding each component's role helps users troubleshoot issues effectively. This knowledge enhances reliability and performance in various applications.

How Duplex Basket Strainers Operate

Duplex basket strainers are essential in many industrial processes. They operate by using two separate filter baskets. When one basket becomes clogged, the other continues to function. This design minimizes downtime. Such efficiency is crucial in systems where flow must be maintained.

When the strainer needs maintenance, the operator can switch to the other basket. This is done with a simple valve operation. The process remains uninterrupted. However, regular checks are necessary to ensure both baskets are clean. Sometimes, users forget to check for debris buildup. This can lead to flow issues. In some cases, this oversight causes unexpected downtime.

The maintenance process can seem straightforward, but it requires attention. Cleaning the strainer is often neglected. Proper training can help operators remember these tasks. Additionally, marking maintenance schedules can improve efficiency. A well-maintained duplex basket strainer ensures a longer lifespan and better performance. Not paying attention can lead to costly mistakes.

Applications of Duplex Basket Strainers in Various Industries

Duplex basket strainers play a vital role in various industries. They are often used in water treatment facilities to ensure clean water supply. Their design allows continuous operation, which means less downtime. Two baskets filter liquid simultaneously. This feature is particularly useful when working with heavy sediment or debris.

In the oil and gas sector, duplex basket strainers help maintain equipment efficiency. They remove contaminants from fluids during extraction and processing. However, operators must regularly inspect and clean the strainers. Neglecting this can lead to decreased performance and possible equipment failure. The strainers are essential, but oversight can lead to costly issues.

Food and beverage manufacturing also utilizes duplex basket strainers. They ensure product safety by filtering out impurities. The strainers must meet specific hygienic standards, which requires ongoing monitoring. Failing to keep strainers in top condition can risk contamination. Regular maintenance is crucial to avoid problems. In all applications, proper handling and attention to detail are necessary for optimal performance.

Benefits of Using a Duplex Basket Strainer for Filtration

A duplex basket strainer is a valuable tool for filtration processes. Its primary benefit lies in continuous operation. One strainer can filter, while the other is in maintenance. This ensures no downtime in operations, which is crucial for many industries. Efficient filtration can lead to better machinery performance and longer equipment life.

Using a duplex basket strainer leads to cost savings over time. Fewer system interruptions mean reduced labor costs. Additionally, the improved efficiency translates to lower energy consumption. This makes it a smart choice for businesses focused on sustainability.

Tips for maintaining your duplex basket strainer are essential. Regular checks can prevent clogs and system failures. Clean the strainers according to the manufacturer’s recommendations. This will ensure optimal function. If you notice fluctuations in pressure, consider inspecting them sooner. Understanding when to replace parts can also save money.

Benefits of Using a Duplex Basket Strainer for Filtration

Related Posts

-

Exploring Duplex Strainer Innovations at the 138th Canton Fair in 2025

-

How to Choose the Right Duplex Basket Strainer for Your Needs in 2025

-

Essential Tips for Choosing a Pneumatic Butterfly Valve?

-

How to Choose the Right Pneumatic Butterfly Valve for Your Applications

-

Top 5 Pneumatic Valves to Watch in 2025: Features and Applications

-

2026 Top Globe Valves Types for Industrial Applications?