Blog

10 Essential Tips for Choosing the Right Air Actuator for Your Projects

In today's rapidly evolving manufacturing landscape, the choice of the right components can significantly impact project efficiency, productivity, and overall performance. Among these essential components, air actuators play a pivotal role in driving automation and operational effectiveness across various industries. According to a recent report by the International Pneumatics Association, the demand for air actuators is projected to grow at a compound annual growth rate (CAGR) of 5.2% over the next five years. This growth is attributed to the increasing need for automation in sectors such as automotive, food processing, and pharmaceuticals, all of which rely heavily on precise and reliable actuation solutions.

As industry expert Dr. Maria Thompson, a leading figure in pneumatic systems research, aptly states, "Selecting the right air actuator is not merely a technical choice; it is a strategic decision that can influence the success of any automation project." With numerous options available in the market, including variations in size, operation, and efficiency, understanding the critical factors in choosing the appropriate air actuator is essential for engineers and project managers alike. This article provides ten essential tips to navigate the complexities of selecting air actuators, ensuring that your projects benefit from optimal performance and cost-effectiveness.

Understanding Air Actuators and Their Applications

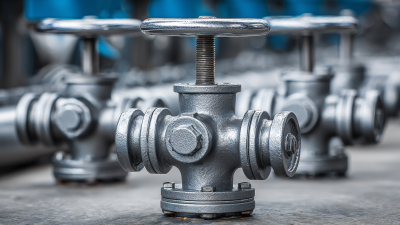

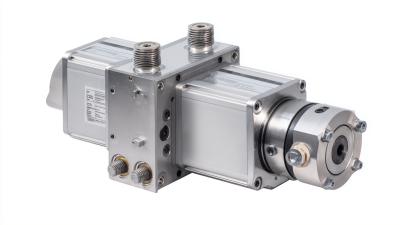

Air actuators are crucial components in pneumatic systems, utilizing compressed air to create motion. They come in various forms, including cylinder-type actuators and rotary actuators, and are widely used across industries for automation and control. Understanding the basic operation of air actuators is essential when selecting the right device for your project. Typically, these actuators convert air pressure into linear or rotational movement, allowing them to perform tasks such as opening and closing valves, pushing and pulling loads, or even driving robotic arms.

When considering air actuators for specific applications, it’s important to evaluate several factors. The environment in which the actuator will operate can greatly influence its performance. For instance, in dusty or humid areas, selecting an actuator with proper sealing and protection ratings is vital to ensure longevity and reliability. Additionally, the load requirements, speed of operation, and available space must all be considered to select an actuator that meets the specific needs of your project. By understanding these key aspects, you can make an informed decision that aligns with the operational demands of your application.

Key Factors to Consider When Selecting an Air Actuator

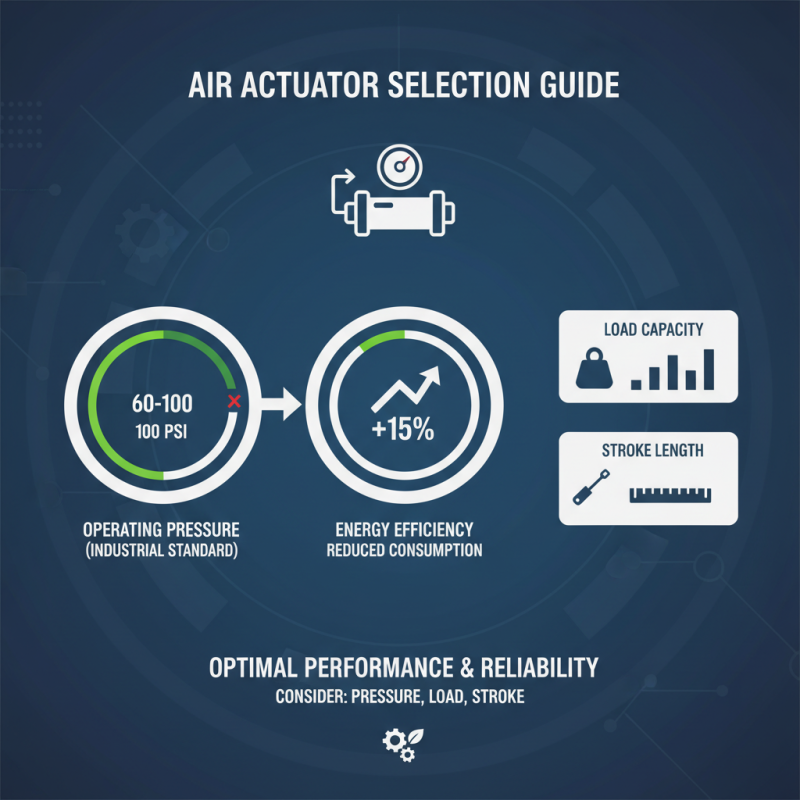

When selecting the right air actuator for your projects, several key factors must be carefully considered to ensure optimal performance and reliability. One critical aspect is the actuator's operating pressure range, which typically falls between 60 to 100 psi for industrial applications. According to a recent report by the International Journal of Applied Science and Technology, actuators that operate efficiently within this pressure range exhibit a significant reduction in energy consumption, improving overall system efficiency by up to 15%. Furthermore, understanding the specific requirements of your application, such as load capacity and stroke length, will play a crucial role in determining the appropriate actuator model.

Another important consideration is the actuator's response time and control features. Industry standards suggest that a response time of less than 200 milliseconds is ideal for most dynamic applications, including robotic systems and automated machinery. Moreover, selecting actuators that offer precise control capabilities, such as proportional control options, can enhance the accuracy of the system while reducing wear and tear. Data from the Manufacturing Automation Study indicates that systems utilizing advanced air actuators with quick response times can achieve productivity increases of up to 20%. By focusing on these key factors, you’ll be better equipped to select an air actuator that meets the specific demands of your project, ultimately leading to improved operational efficiency and performance.

Types of Air Actuators and Their Unique Features

When selecting an air actuator for your project, understanding the different types available and their unique features is critical. Air actuators can be broadly classified into single-acting and double-acting types.

Single-acting actuators use compressed air to move in one direction, relying on a spring mechanism to return to its original position. They are ideal for applications where simple push or pull actions are required. According to a report from the International Journal of Automation Technology, single-acting actuators are commonly used in applications like clamping and cutting, where space is limited and cost is a concern.

On the other hand, double-acting actuators utilize compressed air to move in both directions, which offers greater control and force. These are particularly advantageous in applications that require precise positioning, such as in robotics or process automation. The Fluid Power Journal indicates that the market for double-acting air actuators is expected to grow by 5.2% annually over the next five years, driven by expanding industrial automation and efficiency needs.

Additionally, variations in design—such as pivoting styles, rodless configurations, and the option for adjustable stroke lengths—allow for further customization based on specific project requirements. Understanding these unique features and their applications will significantly aid in making an informed decision that maximizes performance and cost-efficiency in your projects.

Common Mistakes to Avoid When Choosing an Air Actuator

When selecting an air actuator for your specific projects, it is crucial to avoid common pitfalls that can lead to operational inefficiencies or increased costs. One of the most frequent mistakes is underestimating the required force for the application. According to industry reports, about 30% of failed actuator installations stem from inadequate load calculations. Understanding the exact force needs will ensure that the actuator can perform optimally, avoiding potential equipment strains or premature failures.

Another common error is neglecting to consider the environmental conditions in which the actuator will operate. Factors such as temperature fluctuations, humidity, and the potential for corrosive elements can significantly impact actuator performance. Studies suggest that nearly 25% of actuator failures arise from environmental miscalculations. Therefore, assessing whether your selected actuator can withstand these conditions is vital in preserving its longevity and functionality. Taking the time to thoroughly evaluate these aspects will lead to more reliable and efficient actuator operations for your projects.

10 Essential Tips for Choosing the Right Air Actuator for Your Projects - Common Mistakes to Avoid When Choosing an Air Actuator

| Tip Number | Tip | Common Mistakes | Best Practice |

|---|---|---|---|

| 1 | Understand Your Project Requirements | Not assessing specific application needs | Conduct a thorough project analysis |

| 2 | Consider Actuator Size | Opting for a actuator that’s too small or too large | Calculate necessary dimensions accurately |

| 3 | Select the Right Pressure Rating | Ignoring pressure requirements | Check system pressure specifications |

| 4 | Evaluate Cycle Speed | Not accounting for speed in operations | Match actuator speed with process requirements |

| 5 | Assess Environmental Conditions | Disregarding temperature and humidity impacts | Consider materials suitable for the environment |

| 6 | Think About Control Type | Choosing incompatible control systems | Ensure compatibility with existing controls |

| 7 | Check Durability and Maintenance Needs | Selecting options without maintenance plans | Review maintenance schedules and durability ratings |

| 8 | Account for Load Requirements | Overestimating or underestimating loads | Use accurate load calculations |

| 9 | Budget Considerations | Ignoring total cost of ownership | Consider long-term costs, not just upfront pricing |

| 10 | Seek Expert Advice | Making decisions without consulting experts | Engage with professionals in the field |

Tips for Cost-Effective Purchasing of Air Actuators

When it comes to purchasing air actuators, cost-effectiveness is a vital consideration that can significantly impact your project budget. To make informed purchasing decisions, start by clearly defining your project requirements, including the necessary specifications and performance features. Understanding the exact needs of your application allows you to avoid overspending on unnecessary capabilities. Moreover, it's essential to compare prices from multiple suppliers while considering additional costs such as shipping and handling, which can influence the overall price of the actuator.

Another key aspect to consider is the material and design of the air actuators. Opting for durable materials can reduce long-term maintenance costs, saving you money in the long run. Additionally, consider purchasing in bulk if your project size allows for it, as many suppliers offer discounts for larger orders. Don’t overlook the importance of checking for any warranties or service agreements that can further safeguard your investment. Balancing quality and price will ensure that you maximize value while keeping your purchasing streamlined and efficient.

Related Posts

-

Exploring Air Actuator Innovations at the 138th Canton Fair 2025 in China

-

How to Choose the Right Pneumatic Valve for Your Industrial Application

-

Revolutionizing Industrial Automation with Cutting-Edge Pneumatic Valve Actuators

-

Exploring the Future of Pneumatic Control Valves in 2025 Top Digital Innovations

-

Top 10 Globe Valves Types and Their Applications in Industrial Systems You Should Know

-

Why Pneumatic Rotary Actuators Are Essential for Modern Automation