Blog

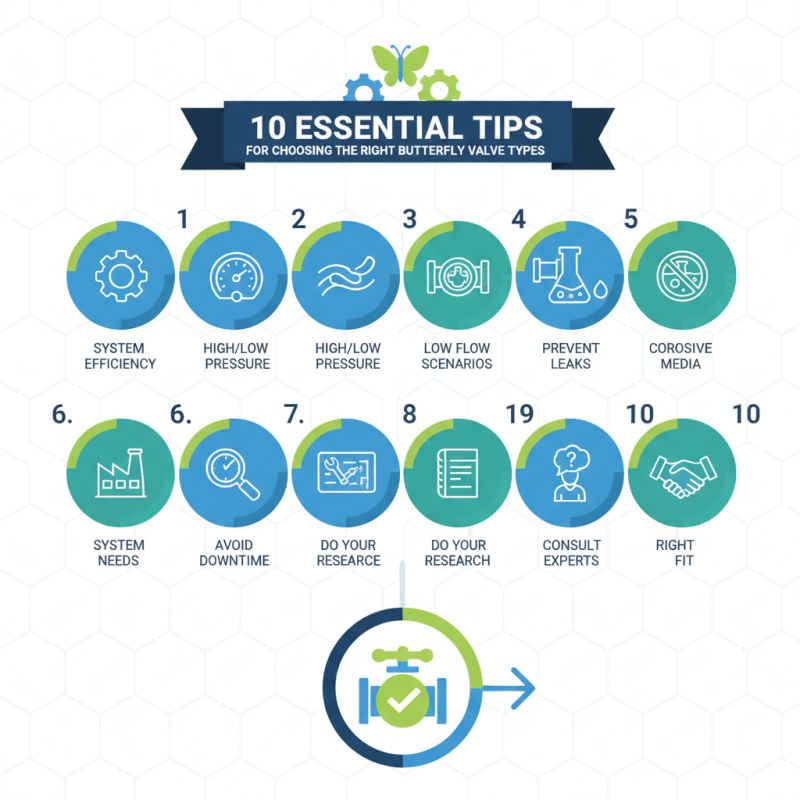

10 Essential Tips for Choosing the Right Butterfly Valve Types?

Choosing the right butterfly valve types is crucial for various industrial applications. John Smith, a leading expert in valve engineering, once stated, "Selecting the right valve type can make or break system efficiency." This reflects the importance of understanding the different styles available.

Butterfly valves are versatile. They come in many types, each suited for specific conditions. Some are better for high-pressure systems, while others excel in low-flow scenarios. With numerous options, it can be overwhelming to find the best fit. The wrong choice may lead to leaks or inefficient flow.

Consideration of the media type is essential. For instance, corrosive materials demand specialized butterfly valve types. Ignoring these factors can lead to costly downtime and repairs. It's vital to reflect on your system’s needs before making a decision. Always do your research and consult experts when in doubt.

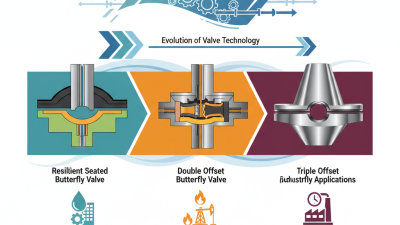

Understanding the Different Types of Butterfly Valves Available

When choosing the right butterfly valve, understanding the different types available is crucial. Butterfly valves come in various designs, each serving specific functions. For example, wafer-style butterfly valves embed between two flanges, while lug-type valves can be bolted to piping without needing flanges. This complexity often causes confusion.

Tip: Assess your system’s pressure, temperature, and flow requirements. Not all valves can handle extreme conditions. Some valves work well in low-pressure systems but fail under high pressure.

Another type is the double-flanged butterfly valve, which features flanges on both sides. This design allows for easy installation and maintenance. However, it may not be suitable for tight spaces.

Tip: Consider your installation environment. Space constraints impact valve selection. A valve might look ideal but could be impractical in your setup.

Choosing the right butterfly valve type requires careful thought. Each design has pros and cons. Evaluate your specific needs. Don't rush this decision; it can save you time and resources in the long run.

Understanding Different Types of Butterfly Valves

Key Factors to Consider When Selecting Butterfly Valves

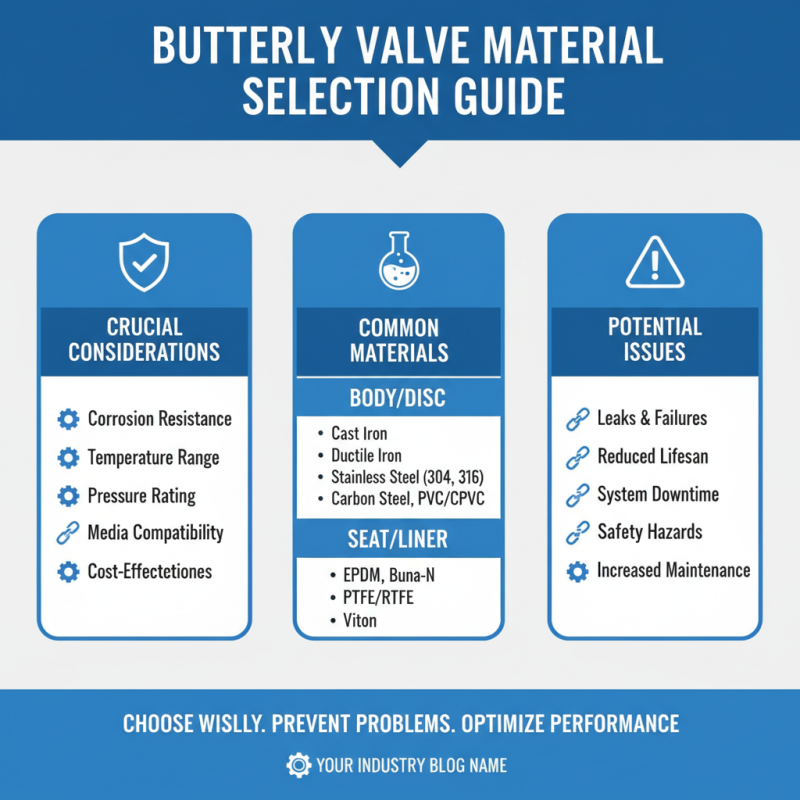

When selecting butterfly valves, several key factors demand careful consideration. Material selection is crucial. Butterfly valves made from stainless steel are ideal for corrosive environments. However, they can be more expensive. For cost-effective solutions, PVC valves work well in non-corrosive settings but may not withstand high temperatures. According to a 2022 industry report, improper material choice impacts the valve’s longevity and functionality.

Next, size and pressure ratings cannot be overlooked. A valve too small may restrict flow, leading to performance issues. In contrast, oversized valves can lead to operational inefficiencies. Valves must match the pipe size and pressure requirements. In a recent study, nearly 30% of process failures were linked to incorrect valve sizing. This highlights the importance of precise calculations and alignment with system demands.

Finally, the design type plays a significant role. Lug-style and wafer-style valves cater to different installation needs. Lug-style valves are easier to replace without disassembling the piping. However, they may be bulkier. In contrast, wafer-style valves can save space but may require more attention to installation techniques. Balancing these factors can get complicated. Always leave room for adjustments in systems, as real-life applications often reveal unanticipated challenges.

Evaluating Material Compatibility for Butterfly Valve Applications

Choosing the right material for butterfly valves is crucial. Industry reports indicate that improper material selection can lead to major issues. The wrong material may result in corrosion, leaks, or even valve failure. Given the various applications, understanding material compatibility is essential.

For instance, in water treatment systems, common materials include PVC and CPVC. However, these materials may not perform well in high-temperature applications. A recent study showed that 30% of installations faced issues due to thermal expansion mismatches. Moreover, certain chemical environments can degrade plastics over time. Regular assessments of material properties are necessary.

Metallic materials, such as stainless steel, are more resilient. Yet, they can be prone to rust if not properly processed. Significant corrosion rates were reported in industrial environments, reaching up to 20% of the total valve life span. An initial choice of inappropriate material can lead to costly repairs. It's vital to conduct thorough evaluations before selecting the right butterfly valve type for specific applications.

How to Assess the Size and Pressure Ratings of Butterfly Valves

When selecting the right butterfly valve, understanding size and pressure ratings is crucial. A valve's size directly affects flow control. Measure the pipe's diameter where the valve will fit. Sizes vary, and choosing inaccurately can lead to poor performance. Aim for a snug fit to prevent leaks.

Pressure ratings determine how much pressure the valve can handle. Common ratings include ANSI classes. Always check the system’s pressure requirements. It’s vital to account for maximum and minimum pressure limits. Overstressing a valve may cause premature failure.

Analyze the application environment as well. Temperature and medium type can impact valve performance. Some valves resist corrosion better than others. A visual inspection might reveal wear or damage. Often, we overlook these factors, assuming the valve will work indefinitely. It’s a mistake to underestimate the importance of these details. Choose wisely; the right valve protects your system.

10 Essential Tips for Choosing the Right Butterfly Valve Types

| Tip Number | Tip Description | Size Consideration (inches) | Pressure Rating (psi) |

|---|---|---|---|

| 1 | Identify the application purpose of the valve. | 2 | 150 |

| 2 | Choose between manual and automated operation. | 4 | 200 |

| 3 | Consider the valve body material based on the medium. | 6 | 150 |

| 4 | Assess the temperature range of the application. | 8 | 300 |

| 5 | Review the connection type (flanged or wafer). | 12 | 150 |

| 6 | Evaluate the required flow control capabilities. | 14 | 250 |

| 7 | Ensure compatibility with existing piping systems. | 16 | 400 |

| 8 | Consider safety and regulatory compliance requirements. | 18 | 150 |

| 9 | Review installation space and accessibility. | 20 | 300 |

| 10 | Consult experts or manufacturers for recommendations. | 24 | 600 |

Maintenance and Durability Considerations for Butterfly Valves

When selecting butterfly valves, maintenance and durability are crucial. Regular inspection ensures that the valve functions properly. According to industry reports, about 30% of valve failures result from inadequate maintenance. This statistic highlights the need for routine checks, including stem seals and seat integrity.

Durability is determined by the materials used. Many butterfly valves are made from stainless steel, which offers excellent corrosion resistance. However, not all environments require high-end materials. In less demanding applications, ductile iron may suffice. The choice affects longevity. Studies indicate that the right material choice can increase a valve's lifespan by over 50%.

Lastly, the installation process also impacts durability. Improperly installed valves may fail earlier. Research shows that 20% of valve failures are linked to installation errors. Highlighting the importance of proper fitting and alignment cannot be overstated. Each of these factors plays a pivotal role in ensuring the reliability of butterfly valves over time.

Related Posts

-

How to Select the Best Butterfly Valve Type for Your Industrial Needs

-

Top 5 Types of Butterfly Valves You Need to Know for Optimal Performance

-

Understanding Different Butterfly Valve Types and Their Applications

-

10 Essential Tips for Choosing the Right Air Actuator for Your Projects

-

Top Motorized Valves for 2025 Which One is Right for Your Needs

-

Understanding Hydraulic Actuators: How They Improve Efficiency in Industrial Automation by 30%