Blog

10 Essential Tips for Choosing the Right Check Valves for Your Projects

In the world of fluid management and control systems, the selection of the right check valves is paramount to ensure efficiency and reliability in various industrial applications. According to the Fluid Control Association, proper valve selection can influence system performance by up to 30%, emphasizing the critical role check valves play in maintaining optimal flow rates and preventing reverse flow. With the global check valve market projected to reach $10 billion by 2025, understanding the intricacies of these components is essential for engineers and project managers.

Industry expert Dr. Mark Thompson, a renowned figure in fluid dynamics, notes, "The choice of check valves can significantly impact not only the safety of fluid systems but also their operational efficiency." His insights highlight the necessity for meticulous evaluation of valve characteristics such as material compatibility, pressure ratings, and installation requirements. As various projects demand different valve specifications, following best practices in check valve selection can lead to enhanced system performance and reduced maintenance costs. In this article, we will explore ten essential tips to guide you in choosing the right check valves for your specific needs, ensuring your projects operate with maximum effectiveness and reliability.

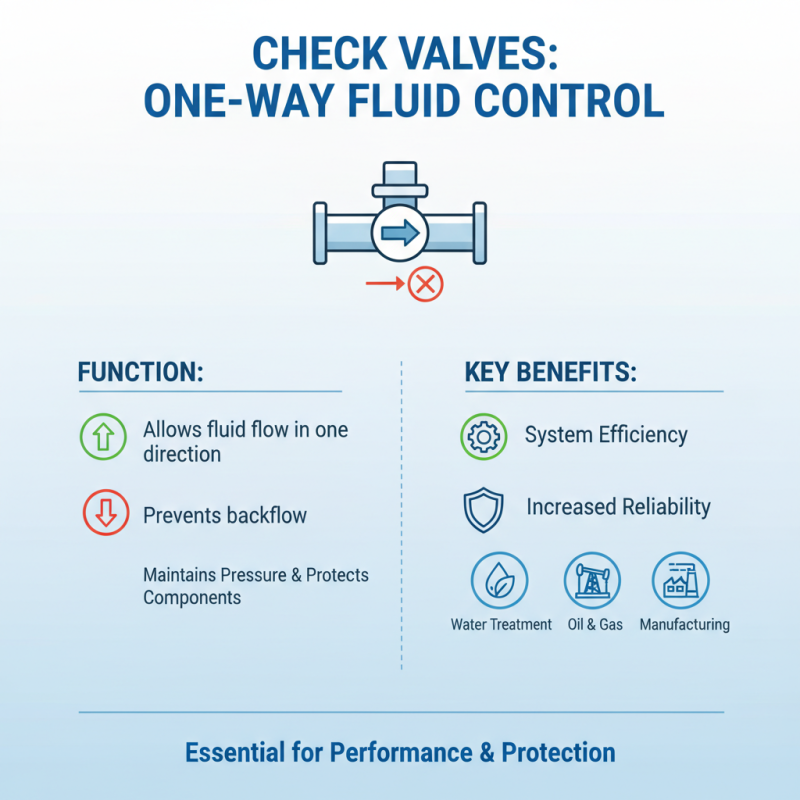

Understanding the Functionality of Check Valves in Fluid Systems

Check valves play a crucial role in fluid systems by allowing fluid to flow in one direction while preventing backflow. This functionality is essential for maintaining pressure and protecting system components from potential damage caused by reverse flow. In various applications, such as water treatment, oil and gas, and manufacturing, the right check valve ensures efficiency and reliability, significantly influencing the overall performance of the system.

When selecting check valves for your projects, consider the specific needs of your fluid system. One essential tip is to match the valve's materials with the fluid being transported. For instance, corrosive fluids require valves made from resistant materials to prevent deterioration over time. Another factor is the valve size; ensuring that the check valve fits your system's specifications is vital for optimal flow performance and pressure management.

In addition to these considerations, assess the pressure ratings and operational characteristics of the check valves. Different types, such as swing, lift, or diaphragm check valves, offer distinct advantages depending on fluid dynamics and flow rates. By understanding the functionality and carefully evaluating these factors, you can make informed decisions that align with your project's requirements, ultimately resulting in a more efficient and dependable fluid system.

Key Materials in Check Valve Construction: Durability and Performance

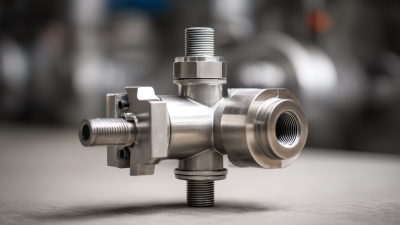

When selecting check valves for your projects, understanding the key materials used in their construction is crucial for ensuring durability and performance. The most common materials include cast iron, stainless steel, and plastic, each offering unique benefits. Cast iron is favored for its strength and resistance to wear, making it suitable for high-pressure applications. Conversely, stainless steel provides excellent corrosion resistance and is ideal for environments exposed to harsh chemicals.

Another important material is plastic, which is lightweight and resistant to a range of chemicals, making it a suitable choice for various applications, especially in water treatment. The choice of material not only affects the lifespan of the valve but also its overall efficiency and reliability. It’s essential to consider the specific applications and conditions—such as temperature, pressure, and type of fluid—to choose the most appropriate material. By focusing on these factors, you can ensure that the check valves used in your projects will perform optimally while withstanding the demands of their environment.

Material Performance Comparison for Check Valves

Pressure Ratings and Flow Characteristics: Selecting the Right Specifications

When selecting check valves for your projects, understanding pressure ratings and flow characteristics is paramount. According to a recent industry report from the American Society of Mechanical Engineers (ASME), the right pressure rating ensures that the valve can withstand system fluctuations, thereby preventing leaks and potential failures. Check valves typically come with pressure ratings ranging from 150 psi to over 3000 psi, depending on the application. It's critical to match the valve's rating to the specifications of your system to maintain operational integrity.

Flow characteristics also play a crucial role in the selection process. A comprehensive study by the Hydraulic Institute indicates that different valve designs, such as swing and lift check valves, exhibit varying flow profiles and pressure drops. For applications requiring minimal turbulence, a low-pressure drop design is essential, as excessive flow resistance can lead to energy losses and system inefficiencies.

Tip: Always consider the material compatibility of the check valve with the fluids in your system to avoid premature wear and failures. Moreover, assessing the installation environment can guide you to choose valves designed for specific conditions, such as high temperatures or corrosive substances. Look for options that align not only with your current requirements but also with future project scalability.

Industry Standards and Certifications: Ensuring Compliance in Valve Selection

When selecting check valves for your projects, understanding industry standards and certifications is crucial to ensuring compliance and performance. Different sectors may have specific requirements that dictate the selection process. Familiarize yourself with standards such as ISO, API, and ASME, which establish guidelines for valve design, materials, and reliability. Adhering to these standards not only enhances safety but also ensures that your systems operate efficiently, reducing the risk of failures over time.

Tip 1 to remember is to always check for the necessary certifications relevant to your industry. A certified valve guarantees that the product has been tested and meets the minimum performance criteria, which is vital for avoiding costly downtimes or safety hazards. Additionally, ensure that your selected valves are compatible with the fluids they will handle, taking into account factors like temperature, pressure, and corrosive effects.

Another key advice is to evaluate the supplier's reputability regarding compliance with industry standards. Not all manufacturers adhere to the same rigorous testing and certification processes. Choose suppliers who can provide documentation proving their products meet relevant regulations, which will help safeguard your project against potential compliance issues and enhance overall system integrity.

10 Essential Tips for Choosing the Right Check Valves for Your Projects - Industry Standards and Certifications: Ensuring Compliance in Valve Selection

| Tip Number | Tip Description | Industry Standard | Certification |

|---|---|---|---|

| 1 | Assess the fluid characteristics to select appropriate materials. | ASME B16.34 | API 6D |

| 2 | Consider the pressure and temperature ratings of the valves. | ASME B16.5 | ISO 9001 |

| 3 | Evaluate installation requirements including space and orientation. | API 598 | CE Certification |

| 4 | Choose the right type of check valve (lift, swing, or ball). | MSS SP-71 | UL Listed |

| 5 | Ensure compatibility with piping systems and fittings. | ANSI/ASME B31.1 | CRN Registered |

| 6 | Review manufacturer specifications and test results. | ISO 17292 | NACE Certification |

| 7 | Check for maintenance and service requirements of the valves. | API 600 | PED Approved |

| 8 | Verify the valve's flow characteristics and performance coefficients. | ANSI/ISA 75.01 | EAC Certification |

| 9 | Assess environmental conditions affecting valve performance. | ASME B31.3 | ISO 14001 |

| 10 | Consult industry experts or technical literature for best practices. | AWWA C508 | AGI Certification |

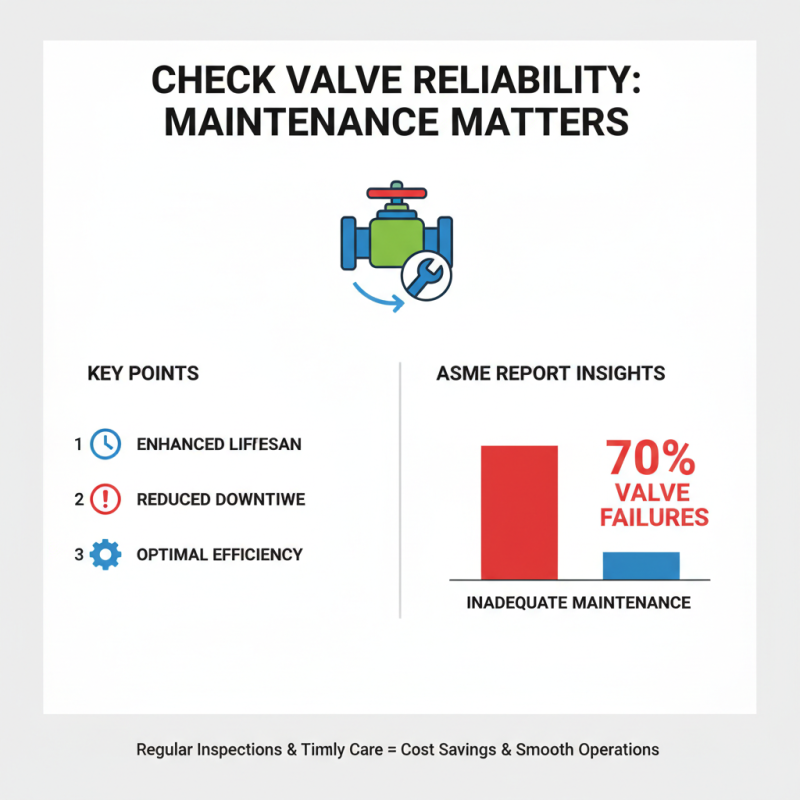

Maintenance Considerations: Enhancing Lifespan and Reliability of Valves

When selecting check valves for industrial applications, maintenance considerations play a crucial role in enhancing the lifespan and reliability of these components. According to recent reports from the American Society of Mechanical Engineers (ASME), a significant portion of valve failures can be attributed to inadequate maintenance practices. Regular inspections and timely maintenance not only prevent costly Downtimes but also ensure that the processes relying on these valves operate smoothly and efficiently.

One essential tip for prolonging the life of check valves is to ensure they are installed correctly. Misalignment during installation can lead to excessive wear and premature failure. Moreover, conducting routine inspections that include checks for leaks, pressure drops, and signs of wear can help in identifying potential issues early. Utilizing predictive maintenance strategies can further enhance reliability by allowing operators to foresee potential failures based on operational data collected over time.

Another important factor is the selection of the right materials for the application's specific conditions. Research indicates that using improperly matched materials can significantly shorten valve life, particularly in harsh environments. Choosing corrosion-resistant materials and considering the weight of fluid flow conditions can lead to better operational longevity. Always remember, consistent and well-planned maintenance strategies paired with carefully chosen components can ensure that your check valves perform optimally, reducing repair costs and extending service life.

Related Posts

-

Understanding the Importance of Spring Check Valve in Modern Plumbing Systems

-

Top Motorized Valves for 2025 Which One is Right for Your Needs

-

How to Choose the Right Pneumatic Valve for Your Industrial Application

-

10 Essential Tips for Choosing the Right Air Actuator for Your Projects

-

Exploring Air Actuator Innovations at the 138th Canton Fair 2025 in China

-

Why Understanding Pneumatic Flow Control Valves is Essential for Efficient Industrial Processes