Blog

Exploring the Future of Control Valves in Sustainable Industrial Applications

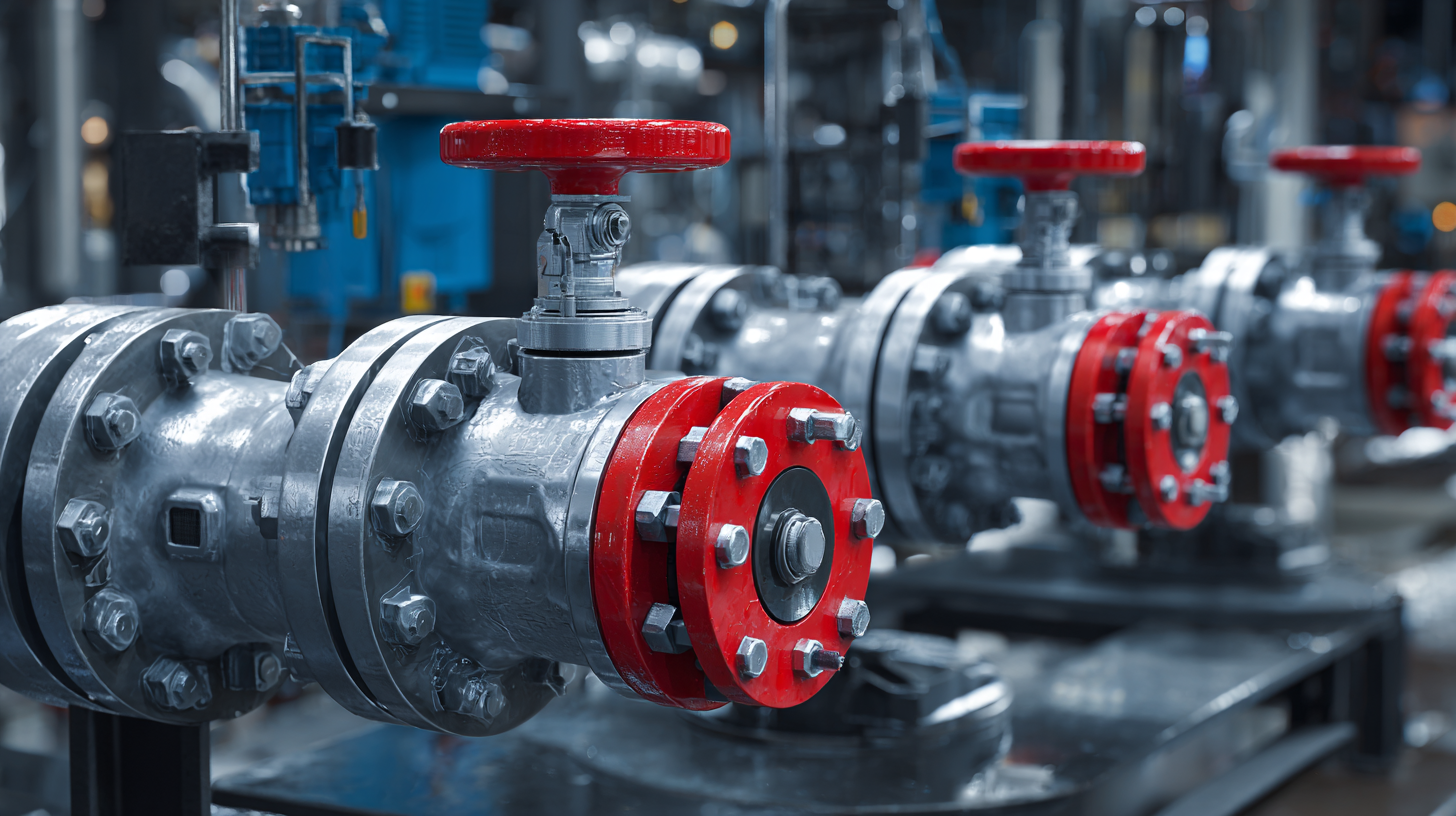

As industries worldwide strive for sustainability, the role of control valves has become increasingly pivotal in enhancing operational efficiency and reducing environmental impact. Control valves are essential components in managing fluid flow and pressure in various industrial processes, and their optimization is crucial for meeting the demands of a greener future. According to a report by MarketsandMarkets, the global control valves market is projected to grow from USD 8.0 billion in 2021 to USD 10.5 billion by 2026, reflecting a compound annual growth rate (CAGR) of 5.5%. This growth is largely driven by the need for improved energy management and the implementation of stricter environmental regulations across industries.

With the advent of Industry 4.0 and smart manufacturing technologies, the integration of advanced control valves offers unprecedented opportunities for optimizing resource use. For example, the deployment of intelligent control systems can significantly enhance the performance and reliability of these valves while minimizing waste. The global trend towards sustainable industrial practices is leading to innovation in control valve designs, ensuring they meet the demands of renewable energy applications, chemical processing, and water management. As industries pivot towards sustainability, understanding the future of control valves within this context is essential for maximizing their potential and ensuring efficient, eco-friendly operations.

Understanding the Role of Control Valves in Sustainable Industrial Systems

Control valves play a crucial role in sustainable industrial systems by regulating the flow and pressure of fluids, thereby enhancing energy efficiency and minimizing waste. By ensuring optimal performance in various processes, these valves can significantly reduce the carbon footprint of industrial operations. Industries such as water treatment, chemical processing, and energy generation benefit notably from integrating advanced control valve technologies that prioritize sustainability.

Tips for selecting control valves for sustainable applications include evaluating materials and designs that support longevity and reduce maintenance needs. Opt for valves that offer precision control to optimize system performance and minimize energy consumption. Additionally, consider smart valve technologies that provide real-time data and monitoring capabilities, enabling better decision-making and resource management.

Implementing best practices such as regular maintenance and updates to valve systems can further ensure their sustainability. Keeping abreast of innovative technologies and market trends can also facilitate the adoption of more efficient valves. By prioritizing these strategies, industries can not only enhance their operational effectiveness but also contribute positively to environmental sustainability.

Key Technologies Driving Innovation in Control Valve Design and Efficiency

The future of control valves in sustainable industrial applications hinges on several key technologies that are driving innovation in their design and efficiency. Advanced materials, such as smart alloys and composites, are enhancing the durability and reliability of control valves, allowing them to withstand harsh environments while reducing maintenance costs. These materials not only improve performance but also contribute to the overall sustainability of industrial processes by minimizing waste and energy consumption.

The future of control valves in sustainable industrial applications hinges on several key technologies that are driving innovation in their design and efficiency. Advanced materials, such as smart alloys and composites, are enhancing the durability and reliability of control valves, allowing them to withstand harsh environments while reducing maintenance costs. These materials not only improve performance but also contribute to the overall sustainability of industrial processes by minimizing waste and energy consumption.

In addition to material advancements, the integration of automation and IoT (Internet of Things) technologies is transforming control valve functionality. Smart control valves equipped with real-time monitoring sensors can optimize flow rates and pressure levels more effectively than traditional models. This data-driven approach enables industries to achieve greater operational efficiency, reduce resource consumption, and respond swiftly to system changes, leading to a more agile and environmentally friendly manufacturing process. As these technologies continue to evolve, control valves will play a crucial role in driving the sustainability agenda across various industrial sectors.

Implementing Smart Control Valves for Enhanced Energy Management

The implementation of smart control valves is revolutionizing energy management in industrial applications, paving the way for sustainable practices. As seen in recent developments, companies are increasingly integrating advanced technologies into their operations. This strategic shift is not only aimed at enhancing efficiency but also significantly reducing greenhouse gas emissions. For instance, the energy-saving measures in public buildings, such as incorporating solar photovoltaic systems, exemplify how resource-efficient technologies can lead to substantial carbon reductions, thereby aligning with global sustainability goals.

Moreover, the market for control valves, including the directional control valves, is projected to experience steady growth, reflecting the broader trend towards smarter industrial applications. With a compound annual growth rate of 3.53% anticipated over the next decade, these technologies are becoming critical in effectively managing energy resources. The evolution of the energy internet, focusing on interconnected technologies, further signifies how smart control solutions will play an essential role in optimizing energy consumption and fostering a greener industrial landscape, aligning with national energy development plans.

Best Practices for Selecting Control Valves in Eco-Friendly Applications

In the quest for sustainable industrial applications, selecting the right control valves is crucial. With advances in technology, modern sensor-operated devices have emerged, enhancing operational efficiency while minimizing environmental impacts. According to recent industry reports, the integration of smart control systems can lead to a 20-30% reduction in energy consumption compared to traditional systems. This not only supports eco-friendly objectives but also contributes to cost savings for industrial operations.

**Tips for Selecting Control Valves:**

When choosing control valves for eco-friendly applications, consider their compatibility with contemporary materials and technologies. Opt for valves that are certified for specific applications, such as those designed for recycling processes, which are essential as the industry moves towards sustainable practices. Moreover, adhering to established standards can help ensure that the selected valves meet performance and safety criteria, ultimately enhancing system reliability.

As industries increasingly focus on reducing their ecological footprint, the importance of effective control valve selection becomes even more pronounced. The market continues to evolve, with innovations emerging in areas like water-saving technologies and pathogen reduction. By prioritizing smart solutions and sustainability in control valve selection, industries can contribute to a greener future while optimizing their operational efficiencies.

Future Trends: How IoT and Automation are Shaping Control Valve Solutions

The rapid evolution of the Internet of Things (IoT) and automation is significantly transforming control valve solutions, particularly in sustainable industrial applications. With IoT integration, control valves are becoming smarter, enabling real-time monitoring and data analytics to optimize performance and efficiency. Sensors embedded within control valves collect vital operational data, allowing for predictive maintenance, reduced downtime, and improved energy management. This connectivity fosters a more responsive and adaptive industrial environment, crucial for meeting the demands of sustainability.

Automation further enhances the capabilities of control valves by streamlining processes and minimizing human error. Advances in machine learning algorithms enable automated systems to analyze and respond to fluctuations in process conditions independently. This not only improves operational efficiency but also ensures compliance with environmental regulations by maintaining precise control over emissions and waste. As industries transition towards greener practices, the incorporation of IoT and automation within control valve design will be pivotal in driving innovation and achieving sustainability goals.

Related Posts

-

Understanding Hydraulic Actuators: How They Improve Efficiency in Industrial Automation by 30%

-

Understanding the Importance of Spring Check Valve in Modern Plumbing Systems

-

Understanding Electric Actuators: Revolutionizing Automation in Modern Industries

-

Understanding the Benefits of Basket Strainers in Industrial Applications

-

Exploring the Future of Basket Strainers at the 138th Canton Fair 2025 in China

-

Exploring Pneumatic Rotary Actuator Innovations at 2025 China Import and Export Fair