Blog

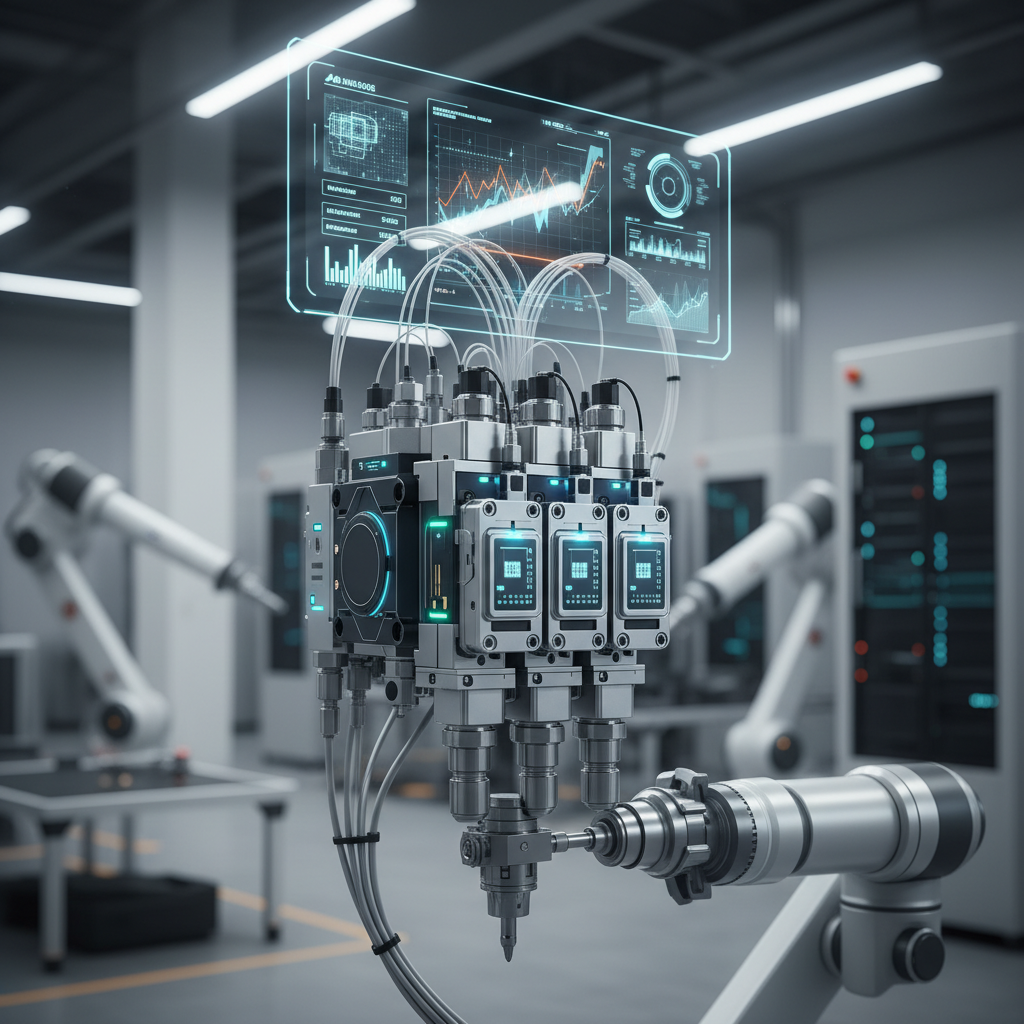

Exploring the Future of Pneumatic Control Valves in 2025 Top Digital Innovations

As we stand on the brink of 2025, the landscape of industrial automation is rapidly evolving, with pneumatic control valves at the forefront of these changes. These vital components play a crucial role in managing and regulating airflow within various systems, ensuring optimal performance and efficiency. With the advent of advanced digital technologies, the functionality and reliability of pneumatic control valves are being transformed, paving the way for innovative applications that promise to enhance industrial processes.

This exploration delves into the top digital innovations intended to revolutionize the operational capabilities of pneumatic control valves. From IoT integration and advanced predictive maintenance to artificial intelligence-driven control systems, the future holds immense potential for optimizing these critical devices. As industries increasingly prioritize automation and smart technologies, understanding how to leverage these innovations will be instrumental in maximizing productivity and performance.

Hence, this guide will provide insights into how organizations can harness the future of pneumatic control valves, ensuring they are well-equipped to navigate the challenges and opportunities that lie ahead.

The Evolution of Pneumatic Control Valve Technologies Towards 2025

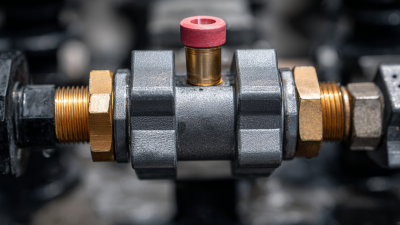

The evolution of pneumatic control valve technologies is poised to significantly reshape industrial processes by 2025. As industries pivot towards automation and digitization, pneumatic control valves are becoming increasingly integrated with advanced digital innovations. The advent of smart sensors and IoT connectivity allows these valves to provide real-time data analytics, facilitating predictive maintenance and reducing downtime. This technological synergy results in enhanced efficiency and flexibility in operational environments, enabling manufacturers to react proactively to system demands.

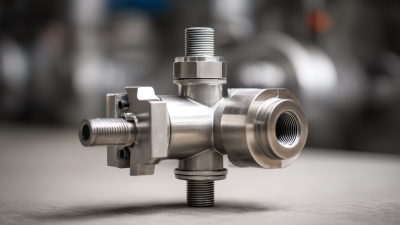

Moreover, advancements in materials and design are creating more robust and efficient valve solutions. The incorporation of lightweight yet durable materials not only improves the valve's performance but also enhances energy efficiency. Additionally, developments in software that drive pneumatic control systems are enabling more sophisticated modeling and simulations, ensuring optimal performance under varying operational conditions. As we approach 2025, the convergence of these technologies promises to elevate the capabilities of pneumatic control valves, aligning them with the needs of modern industries that demand high reliability and adaptability.

Impact of Industry 4.0 on Pneumatic Control Valve Innovations

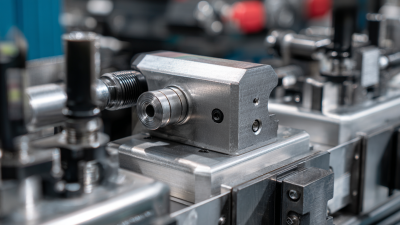

The advent of Industry 4.0 is poised to significantly reshape the landscape of pneumatic control valve innovations by 2025. As manufacturing processes become increasingly automated and interconnected, pneumatic systems are adapting to incorporate smart technologies. According to a report by MarketsandMarkets, the global smart valves market is expected to generate $9.07 billion by 2025, reflecting a compound annual growth rate (CAGR) of over 12%. This growth is driven by the necessity for precision, reliability, and efficiency in controlling fluid dynamics in industries such as manufacturing, oil and gas, and pharmaceuticals.

Moreover, the integration of the Internet of Things (IoT) into pneumatic control systems enhances real-time monitoring and data analytics. With sensors embedded within valves, operators can gain insights into performance metrics and maintenance needs, thus reducing downtime and operational costs. A study by Research and Markets indicates that predictive maintenance solutions that leverage IoT technology can decrease maintenance costs by up to 30%, illustrating the financial viability of such innovations. The convergence of digital technologies with pneumatic control valves will not only optimize existing operations but also pave the way for new applications and efficiencies across various industries.

Key Digital Innovations Shaping the Future of Pneumatic Control Valves

The future of pneumatic control valves is set to be revolutionized by key digital innovations that are enhancing efficiency, precision, and reliability in industrial applications. One significant advancement is the integration of IoT (Internet of Things) technology, which allows for real-time remote monitoring and control. This connectivity enables operators to gather data on valve performance, detect anomalies, and optimize maintenance schedules, thus minimizing downtime and increasing productivity.

Another pivotal innovation is the incorporation of artificial intelligence (AI) and machine learning algorithms into pneumatic systems. These technologies can analyze vast amounts of operational data to predict performance trends and improve decision-making. AI-driven analytics facilitate proactive adjustments in valve settings based on predictive maintenance, which not only enhances system reliability but also extends the lifespan of the equipment. Furthermore, digital twin technology is emerging as a critical tool for simulating valve operations in a virtual environment, allowing engineers to assess performance under various conditions before implementation. This blend of digital innovations is reshaping how pneumatic control valves operate, paving the way for smarter, more efficient industrial processes.

Exploring the Future of Pneumatic Control Valves in 2025 - Top Digital Innovations

| Innovation | Description | Expected Impact | Implementation Year |

|---|---|---|---|

| IoT Integration | Utilizing Internet of Things technology for real-time monitoring and control. | Enhanced operational efficiency and predictive maintenance. | 2025 |

| Artificial Intelligence | Implementing AI for smarter decision-making in valve operations. | Reduced downtime and optimized resource allocation. | 2025 |

| Digital Twin Technology | Creating virtual models of physical valves for simulations and performance tracking. | Improved design and testing processes, leading to fewer failures. | 2025 |

| Edge Computing | Processing data closer to the source to improve speed and reduce latency. | Faster response times and improved operational safety. | 2025 |

| Remote Diagnostics | Utilizing remote monitoring tools for diagnostics and troubleshooting. | Reduced maintenance costs and quicker issue resolution. | 2025 |

Analyzing Market Trends and Projections for Pneumatic Control Valves by 2025

In 2025, the pneumatic control valves market is projected to experience significant growth driven by digital innovations and evolving market trends. As industries increasingly rely on automation and advanced control systems, market insights indicate a compound annual growth rate (CAGR) of 6.5% for valve remote control systems from 2024 to 2034, reflecting a demand surge for enhanced safety regulations and rapid leak isolation technologies. This surge aligns with broader applications of pneumatic control valves across various sectors, including oil and gas, chemicals, and food processing.

Additionally, the segmentation of the market reveals diverse opportunities based on motion types—linear and rotary—and components such as actuators and valve bodies. Notably, the flow control valves market is anticipated to expand significantly, with the hydraulic and pneumatic segments serving critical applications in industries such as power generation and water treatment. As we move through the decade, the projection of over $277.7 billion for the pneumatic components market by 2035 underscores the importance of continuous innovation to meet the growing industrial demands.

Integration of AI and IoT in Enhancing Pneumatic Control Valves' Efficiency

As we look toward 2025, the integration of Artificial Intelligence (AI) and the Internet of Things (IoT) is set to revolutionize the efficiency of pneumatic control valves. The global pneumatic components market is projected to grow significantly, with estimates suggesting a rise from $14.81 billion in 2025 to approximately $21.58 billion by 2032. This growth reflects the increasing demand for advanced automation solutions in various industries, where pneumatic control valves play a crucial role in process automation and control.

The convergence of AIoT will enhance the operational capabilities of these valves, enabling predictive maintenance and real-time monitoring. This amalgamation will empower engineers to reduce downtime and optimize the performance of pneumatic systems. By leveraging AI algorithms and IoT connectivity, facilities can gain insights into system efficiency and performance analytics, ultimately leading to smarter decision-making processes. As the facility management sector increasingly adopts these advanced technologies, we can expect a significant improvement in energy efficiency and operational security. The implementation of AIoT in pneumatic control valves is poised to reshape the standards of efficiency and effectiveness across various applications by 2025.

Future of Pneumatic Control Valves: Efficiency Enhancement through AI and IoT (2025)

This chart illustrates the projected efficiency improvements of pneumatic control valves from 2021 to 2025, highlighting the significant impact of digital innovations such as AI and IoT integration.

Related Posts

-

How to Choose the Right Pneumatic Valve for Your Industrial Application

-

Why Understanding Pneumatic Flow Control Valves is Essential for Efficient Industrial Processes

-

Exploring Air Actuator Innovations at the 138th Canton Fair 2025 in China

-

Revolutionizing Industrial Automation with Cutting-Edge Pneumatic Valve Actuators

-

Understanding the Role of Spring Check Valves in Modern Fluid Systems: A Comprehensive Guide

-

Top 5 Types of Butterfly Valves You Need to Know for Optimal Performance