Blog

2026 How to Choose the Right Actuator Valve for Your Needs?

Choosing the right actuator valve can be challenging. Industry expert John Smith states, "Selecting the correct actuator valve is vital for efficiency." With numerous options in the market, understanding your specific needs is crucial.

When evaluating actuator valves, consider factors like application, operating conditions, and desired performance. An actuator valve affects process control, impacting efficiency and safety. Ignoring these factors could lead to significant operational issues. Ensure that you align the choice of valve with your system requirements.

Additionally, reflect on your current processes. Are they as efficient as they could be? An actuator valve is not just a mechanical component; it's pivotal for system performance. Quality selection can enhance workflow, while poor choices may result in unnecessary costs. Take time to evaluate your options carefully.

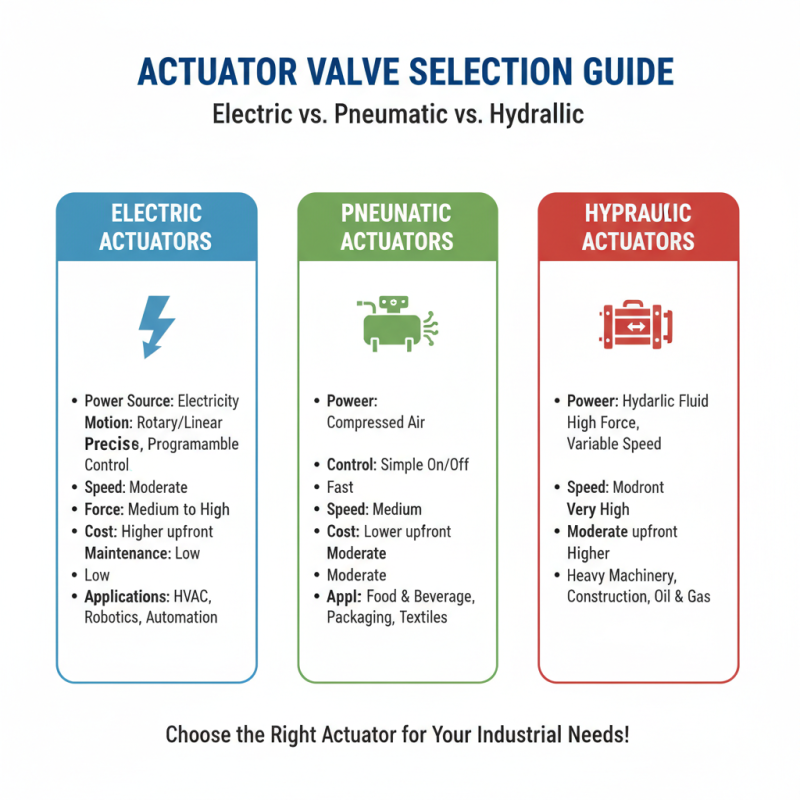

Understanding Actuator Valve Types: Electric, Pneumatic, and Hydraulic

Choosing the right actuator valve is critical for various industrial applications. Understanding the differences between electric, pneumatic, and hydraulic actuators can help make that choice easier.

Electric actuators are known for precision and ease of control. They typically require less maintenance compared to their pneumatic counterparts. According to industry reports, the global electric actuator market is expected to grow by 6% annually. They work well in settings where consistent torque is needed. However, they may struggle in extreme temperatures. Regular checks are essential to ensure they operate correctly.

Pneumatic actuators use compressed air to function. They are fast and can move quickly. Their response time can be under a second, making them ideal for applications requiring rapid actuation. Despite their advantages, they need a reliable air source. Air leaks can lead to inefficiencies and increased operational costs. It's crucial to monitor the air supply regularly.

Hydraulic actuators excel at handling heavy loads. They give high force and are suitable for large industrial machinery. However, they are bulkier and require a more complex setup. They often demand frequent maintenance due to fluid leaks or contamination. Users should be aware of these potential challenges.

Tips: Always assess your specific needs first. Consider speed, load, and available resources. Sometimes, a combination of actuator types may serve better. Be sure to evaluate your environment.

Key Specifications: Torque, Speed, and Control Requirements for Selection

Choosing the right actuator valve is not always straightforward. Torque is a primary specification to consider. It defines the force required to operate the valve fully. A valve needs enough torque to overcome friction and pressure in the system. For example, heavy-duty applications may require torque values exceeding 100 Nm. Underestimating torque can lead to system failures.

Speed is another crucial factor. It determines how quickly an actuator can respond to controls. In process automation, faster response times are often desired. Reports suggest that actuators with speeds over 10 seconds per 90 degrees rotation are common in many industries. However, speed can come at the cost of precision. Balancing speed and accuracy is vital; rushing can lead to errors.

Control requirements also shape the selection process. Options vary from simple on/off control to complex proportional control. Complex systems often need feedback loops for monitoring. Industry data shows that 30% of users face challenges in integrating control systems. Without proper assessment, compatibility issues can arise. Taking the time to analyze these specifications can save significant costs and headaches later on.

2026 How to Choose the Right Actuator Valve for Your Needs?

| Specification | Description | Example Value |

|---|---|---|

| Torque | The rotational force required to operate the valve. | 50 Nm |

| Speed | The time taken for the actuator to open or close the valve. | 2 seconds |

| Control Type | The method used to control the actuator; can be electric, pneumatic, or hydraulic. | Electric |

| Voltage | Operating voltage required for the actuator. | 24 V DC |

| Environmental Rating | The protection level against dust and moisture. | IP68 |

| Feedback Type | The type of feedback used for position sensing. | Absolute encoder |

Matching Valves to Applications: Industry Standards and Best Practices

Choosing the right actuator valve requires careful consideration of application requirements. Industry standards play a crucial role in this process. According to a recent report, 70% of valve failures stem from improper selection. This underscores the importance of aligning valves with specific applications.

Different industries have unique needs. For instance, in the oil and gas sector, valves must withstand extreme pressures. In contrast, water treatment facilities prioritize corrosion resistance. Statistics show that 32% of maintenance costs arise from faulty valves. This highlights the need for informed decision-making when selecting actuator valves.

Best practices suggest conducting thorough evaluations before purchase. End-users should analyze flow requirements, temperature ranges, and medium types. A 2022 survey revealed that 58% of operators felt ill-equipped to choose the right valve. Continuous training and consultation with experts can mitigate this knowledge gap. Proper selection ultimately leads to enhanced efficiency and reduced operational costs.

Evaluating Environmental Considerations: Temperature and Pressure Ratings

When selecting an actuator valve, environmental factors play a crucial role.

Temperature ratings should align with the operational environment.

High temperatures can degrade materials faster than expected. Conversely,

low temperatures may cause brittleness. Each actuator type has a specific temperature range.

Carefully reviewing these ratings is essential.

Pressure ratings are equally important.

They determine how much pressure a valve can handle without failing. A mismatch can lead to leaks or

complete system failure.

Consider the maximum and minimum pressures your system might experience. It's often overlooked, yet it's

vital for safety and efficiency.

Many users overlook the impact of both ratings on valve longevity.

Testing in real-world conditions gives better insights. Environmental changes can lead to unexpected results.

Reflecting on past experiences can help refine your choices. Choose wisely, as your initial decision may have long-term effects.

Cost Analysis: Budgeting for Initial Purchase and Long-Term Maintenance

When budgeting for an actuator valve, consider both the purchase price and long-term maintenance costs. Initial costs can vary significantly. It's crucial to assess your specific needs first. Don’t overlook installation expenses, which can add up quickly. Some valves require special fittings or extra labor.

Tips: Research different types and their expected lifespans. Look for models that are easier to maintain.

Long-term upkeep is equally important. Regular maintenance can prevent costly breakdowns. Consider the availability of spare parts. It’s worth spending time finding a reliable source. A valve with higher initial costs may prove cheaper over time if it lasts longer.

Tips: Track your maintenance expenses for insights into performance. Regular checks can save money later.

In the end, balancing upfront costs with future expenses requires careful planning. Evaluate all aspects, including efficiency, to ensure you make a wise decision. Investing time now can lead to significant savings later.

Related Posts

-

Essential Tips for Choosing a Pneumatic Butterfly Valve?

-

Understanding Different Butterfly Valve Types and Their Applications

-

10 Essential Tips for Choosing the Right Check Valves for Your Projects

-

Best Pneumatic Flow Control Valve Options for Efficient Fluid Management

-

Why Understanding Pneumatic Flow Control Valves is Essential for Efficient Industrial Processes

-

Top 5 Types of Butterfly Valves You Need to Know for Optimal Performance