Blog

Understanding Hydraulic Actuators: How They Improve Efficiency in Industrial Automation by 30%

Hydraulic actuators are at the forefront of enhancing efficiency within industrial automation, demonstrating a remarkable ability to improve operational performance by as much as 30%. According to a recent report by the International Society of Automation, the integration of hydraulic actuators in manufacturing processes leads to significant energy savings and productivity gains. This technology harnesses the power of fluid dynamics to create precise movement and control, allowing for faster cycle times and reduced wear on machinery. In an era where the focus is on optimizing resource utilization and minimizing operational costs, hydraulic actuators have emerged as a vital component in modern automated systems. Their adaptability across various industries—from automotive to aerospace—further underscores their importance. By understanding how hydraulic actuators function and implementing them effectively, companies can unlock substantial improvements in efficiency and sustainability.

The Role of Hydraulic Actuators in Modern Industry

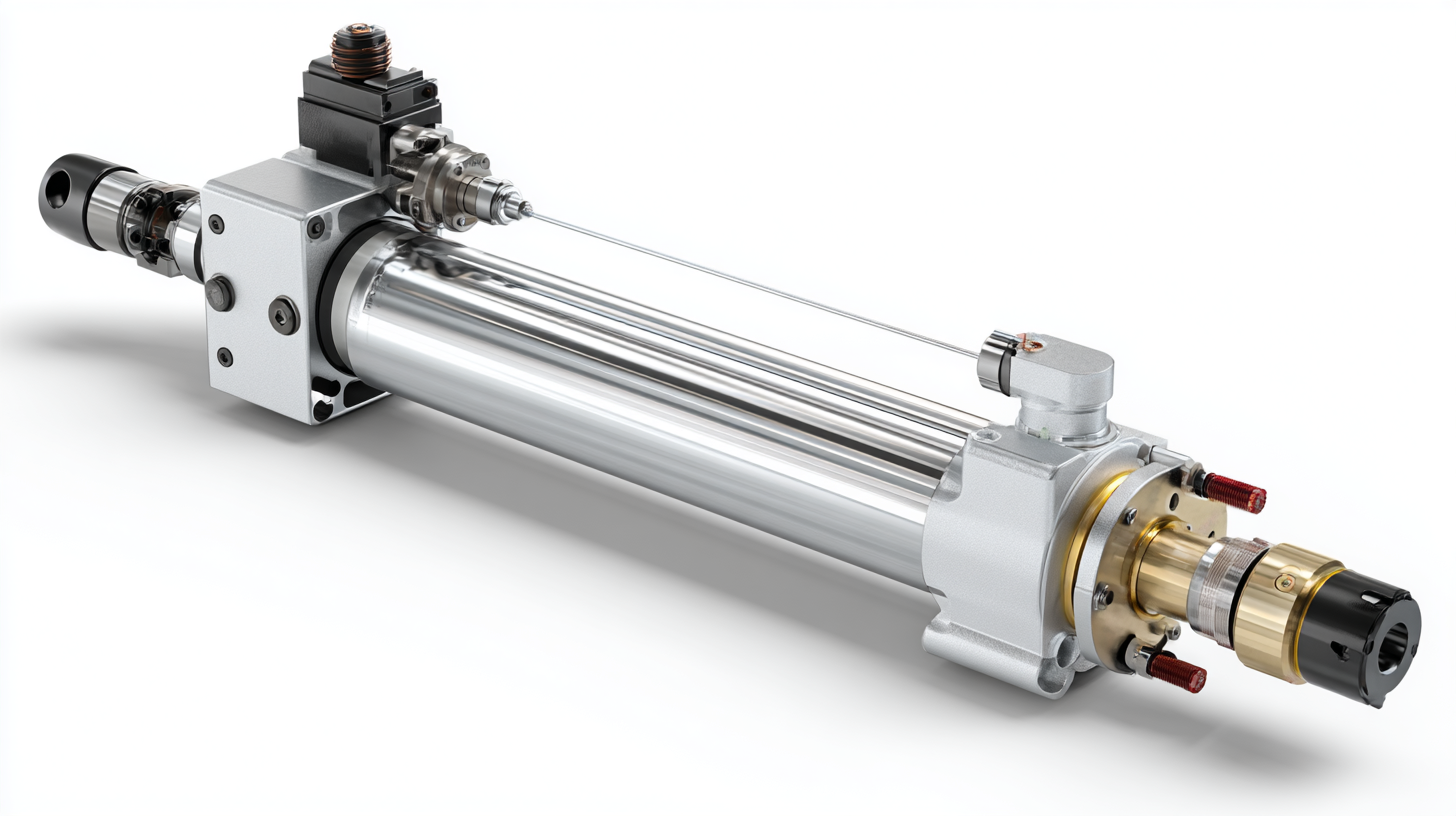

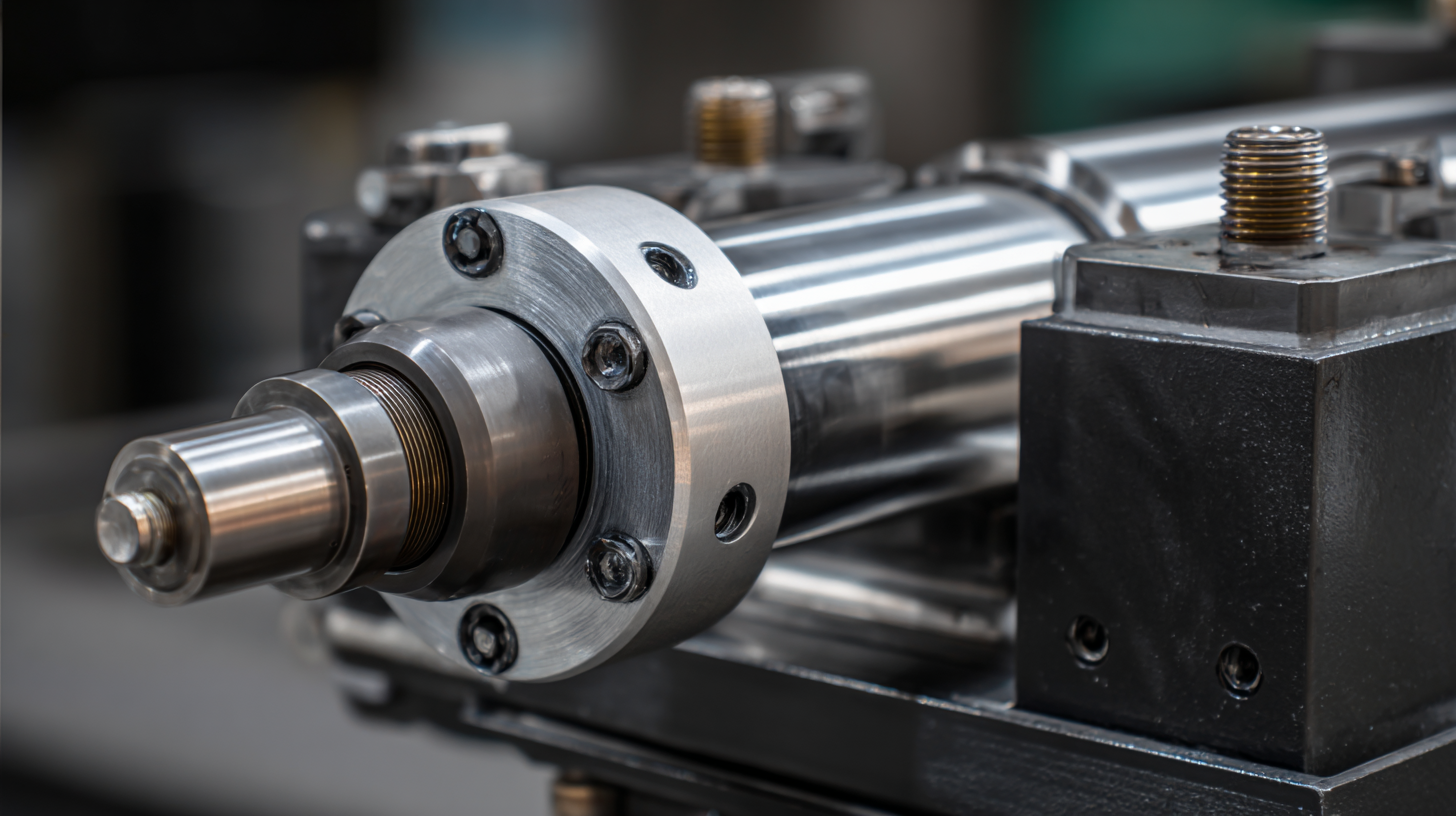

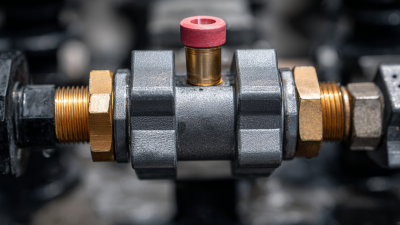

Hydraulic actuators play a crucial role in modern industry by converting hydraulic energy into mechanical movement, which enhances the efficiency of various industrial processes. These devices utilize pressurized fluid to generate force and motion, allowing for precise control over machinery and equipment. This precision is vital in applications ranging from manufacturing to automation, where the ability to manipulate heavy loads swiftly and accurately can significantly reduce operational costs and time.

One of the key advantages of hydraulic actuators is their ability to deliver high power-to-weight ratios, making them suitable for applications where space and weight are critical factors. Their responsiveness and adaptability allow industries to automate processes that were once labor-intensive, leading to a notable increase in productivity. Moreover, as industries strive for sustainability, hydraulic systems can be integrated with renewable energy sources, further enhancing their efficiency and reducing the carbon footprint of operations. By harnessing the power of hydraulic actuators, modern industries can achieve superior performance and reliability in their automation strategies.

Understanding Hydraulic Actuators: Efficiency Improvement in Industrial Automation

This chart illustrates the efficiency improvements achieved by integrating hydraulic actuators in various industrial processes.

Key Benefits of Hydraulic Actuators for Efficiency Gains

Hydraulic actuators are an essential component in industrial automation, offering significant efficiency gains that can reach up to 30%. One of the key benefits of using hydraulic actuators is their ability to exert high force with minimal energy consumption. According to a report by the International Hydraulics Association, hydraulic systems can be 15-30% more efficient compared to electric actuators in heavy-duty applications. This efficiency is primarily attributed to their high power-to-weight ratio and the ability to deliver consistent performance in demanding environments.

Moreover, hydraulic actuators provide improved speed and precise control, enhancing overall productivity in manufacturing processes. A study by TechNavio highlighted that systems relying on hydraulic actuators demonstrated a 25% increase in operational speed, resulting in shorter cycle times and faster output. Additionally, the inherent ability of hydraulic systems to absorb shocks contributes to reduced wear and tear on machinery, leading to lower maintenance costs and extended equipment lifespan. These factors collectively underline the crucial role hydraulic actuators play in boosting efficiency within industrial automation settings.

Tips for Choosing the Right Hydraulic Actuator for Your Needs

When selecting the right hydraulic actuator for your industrial needs, it's essential to consider several key factors that affect performance and efficiency.

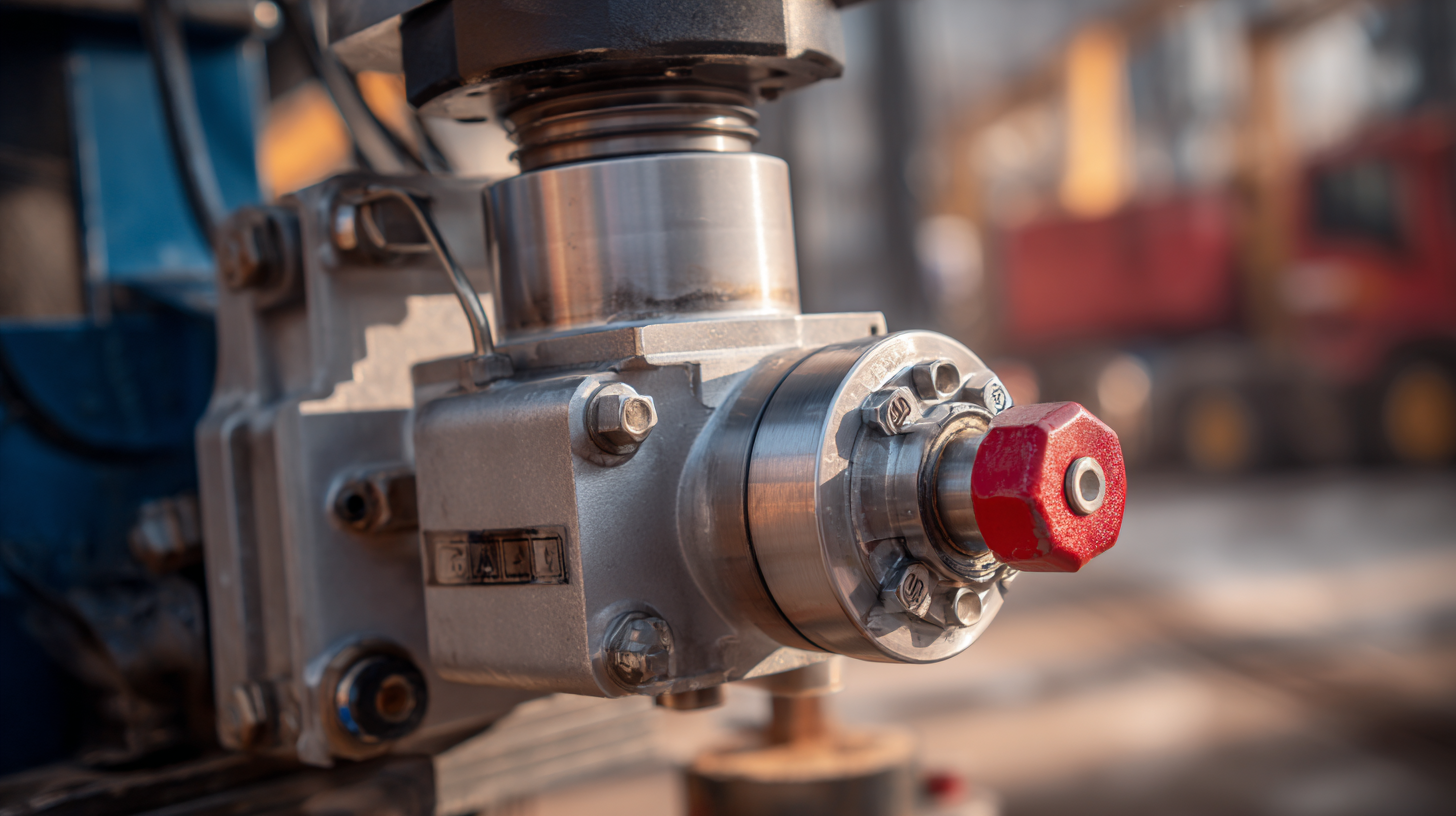

First, assess the load requirements of your application. Hydraulic actuators come in various sizes and power ratings, so accurately determining the necessary force output will help you choose an actuator that meets your specific demands without over-engineering, which could lead to increased costs and inefficiencies.

Another crucial factor is the environment in which the actuator will operate. Consider elements such as temperature, exposure to moisture, and potential contaminants. Actuators designed for harsh conditions may include reinforced seals and materials that provide better durability and longevity. Additionally, think about the actuator’s speed and responsiveness. Selecting an actuator that can deliver precise movements at the required speed will not only enhance efficiency but also improve overall automation processes.

Lastly, compatibility with existing systems is paramount. Ensure the hydraulic actuator integrates seamlessly with the hydraulic circuit and control systems you have in place. Reviewing specifications such as pressure ratings, flow requirements, and mounting configurations will facilitate a smoother installation and operation. With careful consideration of these factors, you can select a hydraulic actuator that optimizes efficiency in your industrial automation processes.

Common Applications of Hydraulic Actuators in Automation

Hydraulic actuators play a pivotal role in enhancing efficiency across various industrial automation applications. Implementing these systems can lead to significant productivity gains, with industry reports indicating an improvement of up to 30% in operational efficiency. This is especially pertinent in sectors like manufacturing, where precision and power are paramount. For example, hydraulic actuators are commonly used in robotic arms, enabling quick and precise movements that are essential in assembly lines. According to a report by the International Federation of Robotics, the use of hydraulic systems in industrial robots is projected to grow by 25% over the next few years, reflecting their expanding role in optimizing processes.

Another notable application of hydraulic actuators is in material handling systems, where heavy lifting and precise positioning are critical. Studies show that incorporating hydraulic technology into conveyor and lifting systems reduces cycle times by approximately 20%, which can substantially enhance throughput. Furthermore, industries such as automotive and food processing leverage hydraulic actuators for tasks like stamping and packaging. A market analysis from Transparency Market Research indicates that the global hydraulic actuator market is expected to reach $29 billion by 2026, signifying robust adoption and investment in hydraulic solutions for automation processes.

Understanding Hydraulic Actuators: How They Improve Efficiency in Industrial Automation by 30% - Common Applications of Hydraulic Actuators in Automation

| Application | Efficiency Improvement (%) | Common Industries | Typical Pressure Range (psi) |

|---|---|---|---|

| Metal Forming | 30% | Manufacturing | 2000 - 3000 |

| Excavation | 35% | Construction | 2500 - 3500 |

| Material Handling | 25% | Logistics | 1500 - 2500 |

| Agricultural Equipment | 30% | Agriculture | 2000 - 3000 |

| Automated Packaging | 28% | Food & Beverage | 1800 - 2800 |

Maintenance Best Practices to Ensure Optimal Performance

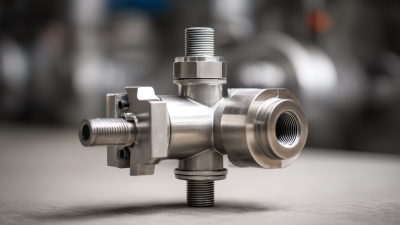

Maintenance best practices are crucial for ensuring optimal performance in hydraulic actuators, which are vital components in industrial automation. Regular maintenance minimizes the risk of unexpected failures, thus enhancing the efficiency of operations significantly—often by as much as 30%. To achieve this, organizations should employ predictive maintenance strategies that utilize advanced technologies such as the Internet of Things (IoT) and Artificial Intelligence (AI). By continuously monitoring the condition of the actuators through sensor data, potential issues can be identified early, allowing for timely interventions that prevent costly downtime.

Moreover, integrating a systematic approach to maintenance not only extends the lifespan of hydraulic actuators but also improves their reliability. Best practices, such as routine inspections, fluid analysis, and the use of digital twins for scenario simulations, enable operators to optimize performance and make informed decisions. Additionally, keeping up with the latest industry standards and technological advancements further ensures that maintenance processes remain effective, thus solidifying the role of hydraulic actuators in advancing industrial automation.

Related Posts

-

Why Understanding Pneumatic Flow Control Valves is Essential for Efficient Industrial Processes

-

How to Choose the Right Basket Strainers for Your Industrial Needs

-

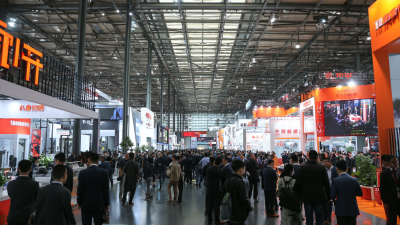

Exploring Air Actuator Innovations at the 138th Canton Fair 2025 in China

-

Exploring the Future of Basket Strainers at the 138th Canton Fair 2025 in China

-

How to Choose the Right Pneumatic Valve for Your Industrial Application

-

Exploring Duplex Strainer Innovations at the 138th Canton Fair in 2025