Blog

Unlocking Precision: How Hydraulic Rotary Actuators Revolutionize Industrial Automation

In the rapidly evolving landscape of industrial automation, the significance of precision in operational efficiency cannot be overstated. Hydraulic rotary actuators, integral to various applications across multiple sectors, stand at the forefront of this precision revolution. According to a recent market analysis by Research and Markets, the global hydraulic actuator market is projected to reach $40 billion by 2025, driven by advancements in automation technologies and the growing demand for high-performance machinery. Hydraulic rotary actuators specifically offer superior torque output, reliability, and control over linear actuators, making them indispensable in applications such as robotics, aerospace, and manufacturing. As industries strive for greater efficiency and adaptability, the adoption of hydraulic rotary actuators emerges as a critical factor in enhancing productivity and achieving precision in automated processes.

Understanding the Basics of Hydraulic Rotary Actuators in Industrial Automation

Hydraulic rotary actuators are essential components in industrial automation, providing precise motion control that enhances operational efficiency. According to a report from Research and Markets, the global hydraulic actuator market is projected to reach $24.9 billion by 2027, growing at a CAGR of 5.2% from 2020. This growth highlights the increasing demand for reliable and efficient motion solutions across various sectors, including manufacturing, construction, and energy.

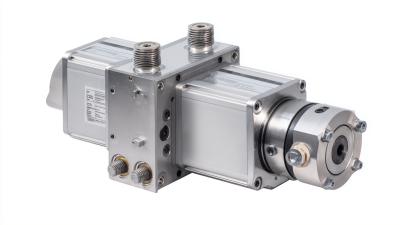

Understanding the basics of hydraulic rotary actuators reveals their significance in complex automated systems. These actuators convert hydraulic energy into rotational motion, allowing for accurate positioning and control of machinery. With their high power-to-weight ratio and ability to handle heavy loads, they outperform traditional pneumatic and electric actuators in many applications. The Energy Efficiency Indicator by the U.S. Department of Energy states that hydraulic systems can achieve efficiency rates of up to 90%, making them not only effective but also sustainable options for automation. As industries continue to embrace smart automation, the role of hydraulic rotary actuators will undoubtedly expand, driving innovation and productivity forward.

Key Advantages of Using Hydraulic Rotary Actuators Over Traditional Actuation Methods

Hydraulic rotary actuators are transforming the landscape of industrial automation by offering several key advantages over traditional actuation methods. One of the primary benefits is their ability to provide high torque and precise control, making them ideal for heavy-duty applications where accuracy is critical. Unlike electric actuators, hydraulic systems can generate significant force from a relatively small footprint, allowing for more compact and efficient machinery design. Additionally, they perform well in challenging environmental conditions, such as extreme temperatures and high humidity, where electric systems might falter.

When integrating hydraulic rotary actuators into your operations, consider the following tips: First, ensure that your hydraulic fluid is compatible with both the actuator and the environment in which it operates. Proper fluid selection can enhance the longevity and efficiency of the system. Second, regular maintenance is crucial; check for leaks and monitor fluid levels to prevent costly downtime. Lastly, invest in training for your team to fully understand the actuator's capabilities and optimal operation techniques, which can maximize productivity and minimize errors.

By leveraging these advantages and best practices, industries can enhance their automation efforts, streamline processes, and ultimately improve overall system performance.

Unlocking Precision: How Hydraulic Rotary Actuators Revolutionize Industrial Automation

| Feature | Hydraulic Rotary Actuators | Traditional Actuation Methods |

|---|---|---|

| Torque Output | High torque density | Lower torque output |

| Response Time | Immediate response | Slower response |

| Size & Weight | Compact and lightweight | Bulkier and heavier |

| Maintenance | Low maintenance cost | Higher maintenance frequency |

| Energy Efficiency | More energy-efficient | Less energy-efficient |

| Versatility | Highly versatile applications | Limited applications |

Exploring Industry-Specific Applications of Hydraulic Rotary Actuators for Enhanced Efficiency

Hydraulic rotary actuators are transforming industrial automation by providing precise and efficient movement in various applications. In sectors such as manufacturing, automotive, and aerospace, these actuators excel in tasks requiring controlled, high-torque motions. Their ability to operate under extreme conditions and deliver consistent performance has made them indispensable in systems such as robotic arms, conveyor belts, and automated assembly lines.

Tip: When selecting a hydraulic rotary actuator for your application, consider factors like load requirements, rotational speed, and environmental conditions. Properly matching the actuator's specifications with the application's needs ensures optimal performance and longevity.

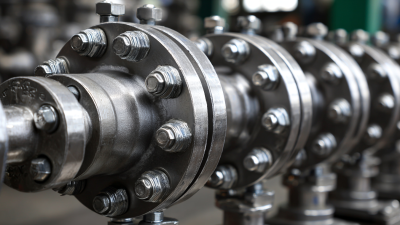

Moreover, the versatility of hydraulic rotary actuators means they can be tailored for specific industry needs. For example, in the oil and gas sector, these actuators are used for valve control and pipeline management, ensuring seamless operations. In the food processing industry, they provide reliable control for machinery handling ingredients, improving efficiency and reducing downtime.

Tip: Regular maintenance and inspections of hydraulic systems can prevent costly failures. Implement a routine checkup schedule to monitor performance and address any potential issues early. This proactive approach not only extends the lifespan of the actuators but also enhances overall productivity in your operations.

Analyzing Market Growth Trends: The Rise of Hydraulic Actuators in Industrial Automation

The global automotive actuator market is witnessing significant growth, with its value forecasted to reach $24.67 billion in 2024, climbing to an astounding $39.40 billion by 2032. This surge is closely linked to the increasing demand for advanced automation solutions across industries, particularly in automotive manufacturing. The integration of hydraulic rotary actuators within automated systems allows for enhanced precision and efficiency, ultimately revolutionizing operational capabilities. As industries pivot toward more automated processes, the dependency on reliable actuators is set to become more pronounced.

Driven by the evolution of robotics, artificial intelligence, and machine learning, the trends in industrial automation underscore the importance of actuators in actuation systems. With hydraulic actuators leading the charge, their unique advantages in terms of power output and durability make them indispensable in key sectors, including oil and gas, energy, and aerospace. The expanding scope of automation coupled with advances in actuator technology not only supports the rise of hydraulic solutions but also reinforces the continuous transformation of industrial environments aiming for unprecedented levels of productivity and performance.

Best Practices for Implementing Hydraulic Rotary Actuators in Automation Systems

The integration of hydraulic rotary actuators is reshaping industrial automation by enhancing precision and efficiency in various applications. According to the ISA-96 series of standards, which serve as a guiding framework for the specification and operation of valve actuators, proper implementation can significantly improve system performance. These standards highlight the importance of adhering to design criteria that ensure reliability and functionality in control systems.

When considering best practices for implementing hydraulic rotary actuators, it's crucial to assess the specific requirements of your automation system. This includes evaluating the torque, speed, and control mechanisms necessary for optimal operation. For instance, incorporating a feedback loop can enhance precision in positioning, which is vital for tasks in automated assembly lines.

Tips:

1. Regularly review and update maintenance protocols to ensure long-lasting performance of hydraulic actuators.

2. Utilize simulation software to model how different actuator configurations will interact within your automation system before actual implementation. This can help identify potential issues and optimize efficiency.

3. Engage with professional standards like those in the ISA-96 series to align your actuator specifications with industry best practices, ensuring optimal compatibility and performance.

Related Posts

-

Why Pneumatic Rotary Actuators Are Essential for Modern Automation

-

How to Select the Best Butterfly Valve Type for Your Industrial Needs

-

Exploring Pneumatic Rotary Actuator Innovations at 2025 China Import and Export Fair

-

How to Choose the Right Basket Strainers for Your Industrial Needs

-

Exploring Duplex Strainer Innovations at the 138th Canton Fair in 2025

-

Exploring Air Actuator Innovations at the 138th Canton Fair 2025 in China