Blog

Why Are Check Valves Essential for Fluid Control Systems?

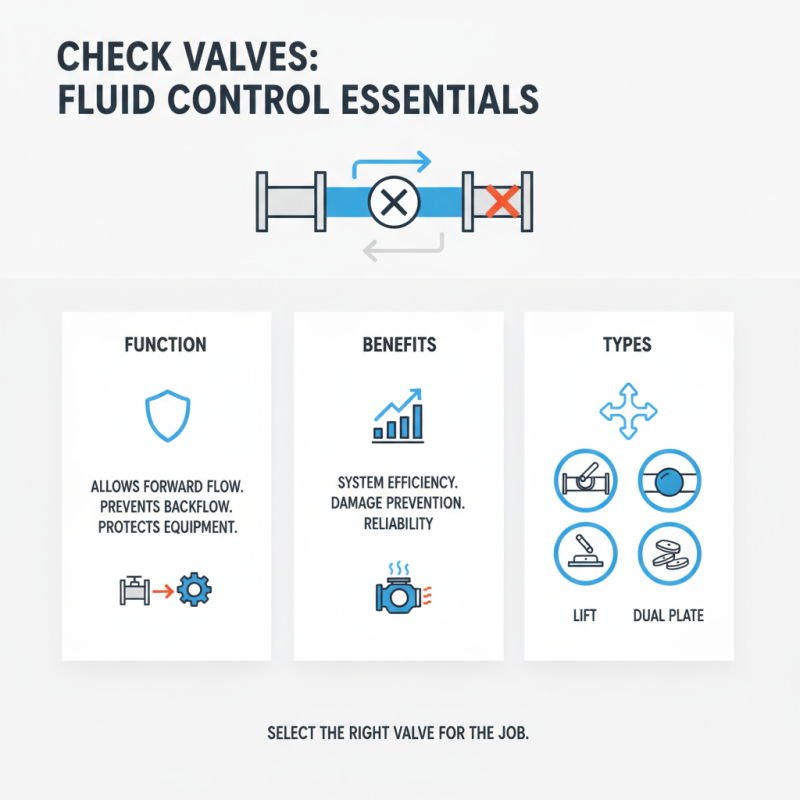

Check valves play a critical role in fluid control systems. These devices ensure the flow of liquids or gases occurs in one direction. This prevents backflow, which can cause damage to equipment and systems. The importance of check valves cannot be overstated.

In many industries, check valves help maintain system integrity. For example, in water supply systems, they prevent contamination. In chemical processing, they protect sensitive equipment from reverse flow. Without check valves, systems can fail, leading to costly repairs and downtime.

However, not all check valves are created equal. The choice of a valve should match system requirements. Factors like pressure, temperature, and fluid type are crucial for optimal performance. To avoid issues in the future, regular inspection and maintenance are also necessary. This ensures reliability and longevity in fluid control systems.

Types of Check Valves Used in Fluid Control Systems

Check valves play a vital role in fluid control systems. They allow flow in one direction while preventing backflow. This feature protects equipment and maintains system efficiency. Several types of check valves cater to different applications. Understanding these varieties helps in selecting the right one.

Swing check valves are commonly used. They have a disc that swings open and closed. This design works well for low-pressure drops. However, they might close slowly, which can lead to water hammer. On the other hand, lift check valves use a disc that moves straight up and down. They are ideal for high-pressure systems but may require more space.

Ball check valves are another option. They use a ball to block reverse flow. They are simple and effective but can get stuck sometimes. Then there are diaphragm check valves. These use a flexible diaphragm that seals off the flow. They can handle more viscous fluids but might need regular maintenance. Each type has its strengths and weaknesses, making it essential to choose wisely based on your specific needs.

The Functionality of Check Valves in Preventing Backflow

Check valves play a critical role in fluid control systems. These devices ensure that fluids flow in one direction only. This simple yet vital function helps maintain system integrity. When pressure drops, check valves close automatically. This action effectively prevents backflow, which can cause contamination or system failures.

Consider a scenario where a pipe carries clean water. If backflow occurs, pollutants from the main line can contaminate the clean water. The consequences can be severe, leading to costly repairs and safety hazards. Check valves serve as guardians in such situations. They help maintain the quality of the fluid and the efficiency of the system.

However, the positioning and sizing of check valves are crucial. An incorrectly sized valve can create excessive pressure drops or may not close properly. Regular maintenance is also essential. Neglected check valves can become stuck or damaged, losing their effectiveness. It’s important to periodically inspect these devices and address any concerns. Overlooking these factors can lead to significant challenges in fluid control systems.

Why Are Check Valves Essential for Fluid Control Systems? - The Functionality of Check Valves in Preventing Backflow

| Dimension | Data | Description |

|---|---|---|

| Material | Brass | Durable and corrosion-resistant, suitable for various fluid types. |

| Size | 1 inch - 6 inches | Variety of sizes available for different applications. |

| Pressure Rating | 150 PSI | Can handle pressure up to 150 PSI, ideal for most industrial applications. |

| Temperature Range | -20°F to 200°F | Operational in a wide range of temperatures. |

| Application | Water, Oil, Gas | Commonly used in various fluid media, ensuring backflow prevention. |

Applications of Check Valves in Various Industries

Check valves play a vital role in fluid control systems across various industries. These devices allow fluid to flow in one direction while preventing backflow. This functionality is critical in applications such as wastewater management, oil and gas, and food processing. For instance, in wastewater treatment plants, check valves ensure that contaminated water does not flow back into clean systems.

In the chemical manufacturing sector, check valves are essential for maintaining the integrity of pumping processes. They prevent reverse flow when pumps are shut down, protecting equipment from back pressure. Moreover, they help maintain consistent pressure levels, which can be challenging in fluctuating conditions. However, choosing the wrong type of check valve can lead to system inefficiencies.

In the food and beverage industry, hygiene is paramount. Check valves help preserve the quality of liquids by preventing contamination. Backflow can introduce harmful bacteria, risking product safety. Proper installation and regular maintenance are necessary but often overlooked. Without consistent attention, even the best systems can fail.

Benefits of Utilizing Check Valves for System Efficiency

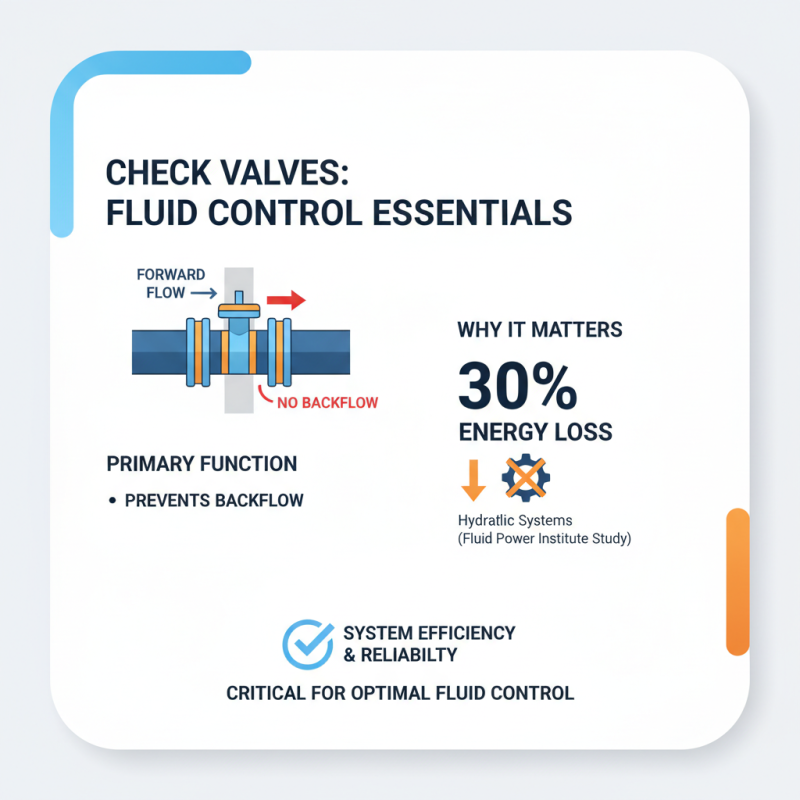

Check valves play a pivotal role in fluid control systems. Their primary function is to prevent backflow, a critical aspect in maintaining system efficiency. A study by the Fluid Power Institute indicates that improper backflow can lead to up to 30% energy losses in hydraulic systems. Such losses emphasize the need for effective check valve integration.

Utilizing check valves brings significant benefits. They help maintain pressure and ensure that fluid only flows in the intended direction. This directionality minimizes damage and prolongs the life of other components. According to a report by the American Society of Mechanical Engineers, systems equipped with check valves operate 25% more efficiently than those without. A well-placed check valve can save both energy and maintenance costs.

Tips: Regularly inspect your check valves for wear and tear. Even small leaks can hinder efficiency. Consider installing a test port to monitor performance. Be mindful that not all check valves suit every system. Choose wisely based on your specific application needs.

Maintenance and Troubleshooting of Check Valves in Fluid Systems

Check valves play a critical role in maintaining the integrity of fluid control systems. They ensure that fluid flows in one direction, preventing backflow that can cause damage. According to a report from the Fluid Control Association, improper maintenance of check valves can result in a significant increase in operational costs, leading to potential losses of up to 30% in efficiency.

Regular maintenance is essential for check valves. Inspection should occur at least once every six months. Signs of wear, such as leaks or inconsistent flow, must be addressed immediately. Failure to do so may lead to catastrophic system failure. Many professionals often overlook small leaks, thinking they are insignificant. But even minor issues can escalate into major problems.

Troubleshooting check valves requires keen attention. One common issue is the presence of debris that hinders operation. It can be easy to dismiss this, but failing to clean or replace the valve can create larger issues down the line. In fact, studies show that 25% of reported fluid system failures are linked to valve malfunctions. Understanding these factors is crucial for effective management of fluid control systems.

Related Posts

-

2026 Top Check Valves Types and Their Applications Guide?

-

10 Essential Tips for Choosing the Right Check Valves for Your Projects

-

Understanding the Importance of Spring Check Valve in Modern Plumbing Systems

-

Revolutionizing Industrial Automation with Cutting-Edge Pneumatic Valve Actuators

-

How to Choose the Right Pneumatic Butterfly Valve for Your Applications

-

2026 How to Choose the Right Actuator Valve for Your Needs?