Blog

Understanding the Importance of Spring Check Valve in Modern Plumbing Systems

In contemporary plumbing systems, the spring check valve plays a critical role in maintaining efficient fluid flow and preventing backflow, which can lead to system failures and contamination. According to a report by the Plumbing Manufacturers International (PMI), approximately 22% of plumbing system problems are attributed to backflow incidents, emphasizing the necessity of reliable check valves. The spring check valve utilizes a spring mechanism to ensure that water flows in one direction while automatically closing to prevent reverse flow, thus safeguarding the integrity of the plumbing infrastructure. A study published in the Journal of Hydraulic Engineering revealed that systems with properly functioning check valves experienced a 30% reduction in maintenance costs, highlighting their importance not only in enhancing performance but also in promoting economic efficiency. Understanding the importance of the spring check valve is essential for anyone involved in plumbing design and maintenance, as they are pivotal in preventing costly damages and ensuring the longevity of plumbing systems.

The Role of Spring Check Valves in Preventing Backflow

Spring check valves play a crucial role in modern plumbing systems, particularly in preventing backflow, which can lead to contamination of potable water. Backflow occurs when water flows in the opposite direction due to pressure changes in the plumbing system, often caused by a sudden drop in water pressure or a break in the line. The effective use of spring check valves can mitigate these risks by ensuring that water can flow in one direction only. According to the latest Uniform Plumbing Code revisions, backflow prevention devices, including check valves, are increasingly being emphasized to maintain public health standards.

In regions susceptible to flooding and severe weather, such as during spring thaws, the importance of such valves becomes even more pronounced. For instance, proactive measures like installing spring check valves can significantly reduce the risk of contamination during heavy rains or snowmelt. A recent program in flood-prone neighborhoods highlights the need for such preventive infrastructure, targeting basement backups that can exacerbate water quality issues. As the boiler feed check valve market is expected to grow substantially, with projections reaching USD 2,055 million by 2032, the demand for reliable backflow prevention methods will likely continue to rise, underscoring the essential role of spring check valves in safeguarding our water systems.

Key Components and Mechanisms of Spring Check Valves

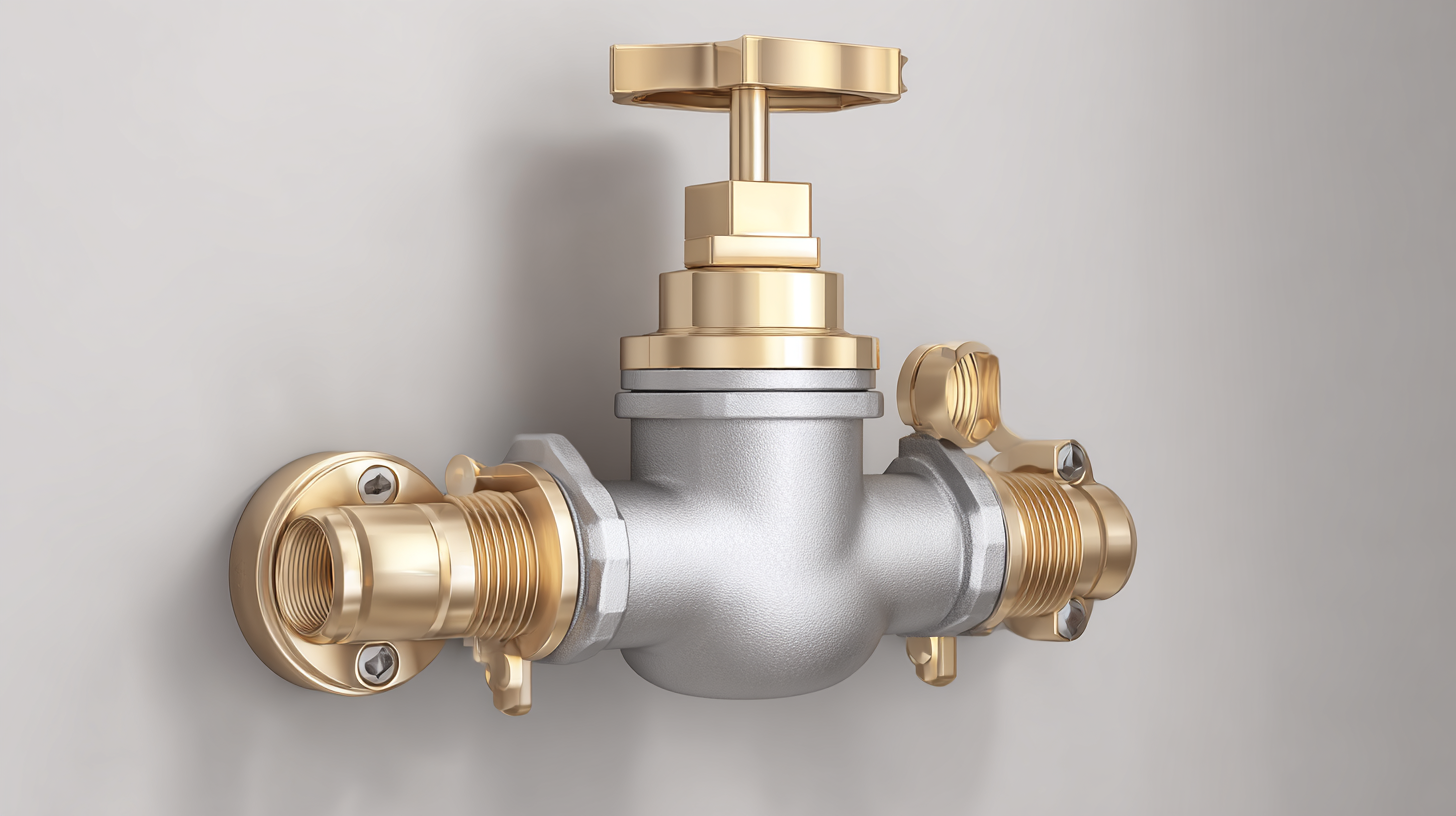

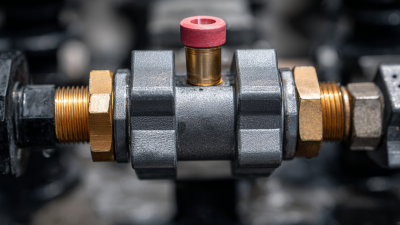

Spring check valves play a crucial role in modern plumbing systems by preventing backflow and ensuring the uninterrupted flow of liquids. These valves consist of key components, including the valve body, spring, and sealing element. The valve body is designed to withstand the pressure of the fluid while providing a clear passage for flow. The spring mechanism is essential, as it keeps the sealing element in place when the water flows in the intended direction, allowing the valve to close automatically if the flow attempts to reverse.

Spring check valves play a crucial role in modern plumbing systems by preventing backflow and ensuring the uninterrupted flow of liquids. These valves consist of key components, including the valve body, spring, and sealing element. The valve body is designed to withstand the pressure of the fluid while providing a clear passage for flow. The spring mechanism is essential, as it keeps the sealing element in place when the water flows in the intended direction, allowing the valve to close automatically if the flow attempts to reverse.

When selecting a spring check valve, consider the material and size that best suits your plumbing system. For residential applications, brass or PVC valves are common choices due to their durability and resistance to corrosion. It’s also important to ensure that the valve is properly installed at a suitable angle to guarantee optimal performance.

Tips: Regularly inspect your spring check valves for signs of wear or damage, as a malfunctioning valve can lead to leaks or backflow issues. Pay attention to the pressure levels in your plumbing system and replace any outdated components to maintain efficiency. Additionally, always consult a professional if you're unsure about the compatibility of new valves with your existing plumbing setup.

Benefits of Using Spring Check Valves in Plumbing Applications

Spring check valves play a critical role in modern plumbing systems, providing several benefits that enhance functionality and longevity. One key advantage is their ability to prevent backflow, which can cause contamination of clean water sources. According to a report by the American Society of Plumbing Engineers, backflow incidents can lead to significant health risks, with estimates suggesting that up to 20% of waterborne illnesses stem from contaminated drinking water. By employing spring check valves, plumbings can mitigate these risks effectively, ensuring safe drinking water and compliance with health regulations.

Additionally, spring check valves contribute to energy efficiency within plumbing systems. A study by the Department of Energy highlights that integrating check valves can reduce energy loss by preventing unwanted reverse flow, leading to operational savings. These valves are designed for low-pressure applications and can operate silently, which minimizes noise in residential and commercial settings. Their robust construction and reliable performance also mean lower maintenance costs over time, which is crucial for both property owners and those in facility management. By investing in high-quality spring check valves, plumbing systems can achieve greater efficiency, safety, and durability.

Common Applications of Spring Check Valves in Modern Systems

Spring check valves play a crucial role in modern plumbing systems, facilitating reliable one-way fluid flow and preventing backflow that could disrupt system performance. According to a report by the Plumbing Manufacturers International (PMI), approximately 25% of plumbing failures are attributed to backflow issues, emphasizing the need for effective check valves in safeguarding against such problems. These valves are commonly employed in various applications, including residential drainage systems, commercial water supply lines, and even in HVAC systems to maintain efficiency and prevent cross-contamination.

In addition to their widespread use in general plumbing, spring check valves are essential in specific industrial applications. For instance, a study published in the Journal of Mechanical Engineering suggests that their use in water treatment plants can reduce energy costs by up to 10% by ensuring that water is only moving in the desired direction. Furthermore, in irrigation systems, these valves prevent back-siphoning, which can compromise soil quality and plant health. The increasing recognition of the advantages of spring check valves is driving their adoption across multiple sectors, making them a vital component in the landscape of modern plumbing systems.

Maintenance Tips for Ensuring Optimal Performance of Spring Check Valves

Spring check valves are crucial components in modern plumbing systems, providing reliable prevention against backflow. However, like any mechanical device, they require regular maintenance to ensure optimal performance. Proper care extends the lifespan of these valves and guarantees effective operation, minimizing the risk of plumbing issues.

One essential tip for maintaining your spring check valves is to perform routine inspections. Look for any signs of wear and tear, such as corrosion or sediment buildup, which could hinder their function. Cleaning the valve regularly ensures that debris does not accumulate, keeping the flow smooth and uninterrupted. Additionally, checking the spring mechanism for functionality can prevent future complications.

Another important aspect of maintenance is ensuring proper installation. The valve should be positioned correctly within the plumbing system to allow for maximum efficiency. If there are any leaks or irregularities, consider retightening or replacing the fittings. Keeping an eye on water pressure and flow rates can also indicate when a check valve requires attention, allowing for timely repairs and replacements.

Related Posts

-

Understanding the Role of Spring Check Valves in Modern Fluid Systems: A Comprehensive Guide

-

Exploring Air Actuator Innovations at the 138th Canton Fair 2025 in China

-

How to Select the Best Butterfly Valve Type for Your Industrial Needs

-

How to Choose the Right Pneumatic Valve for Your Industrial Application

-

Why Pneumatic Rotary Actuators Are Essential for Modern Automation

-

Exploring Pneumatic Rotary Actuator Innovations at 2025 China Import and Export Fair