Blog

Top Pneumatic Flow Control Valve Types Explained: Choosing the Right One

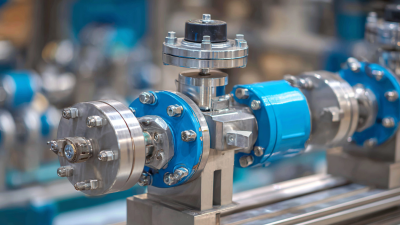

In the world of industrial automation, the importance of selecting the right pneumatic flow control valve cannot be overstated. As an essential component in controlling the flow and pressure of pneumatic systems, these valves play a critical role in ensuring efficiency and safety within various applications. According to Dr. Emily Carter, a leading expert in pneumatic systems, "Choosing the appropriate pneumatic flow control valve can significantly enhance the performance and longevity of your equipment."

Understanding the different types of pneumatic flow control valves available is crucial for engineers and technicians alike. Each type has unique characteristics and functionalities that suit specific applications, which can ultimately influence the success of a system's operation. From needle valves to proportional control valves, the choices can be overwhelming.

This guide will explore the various types of pneumatic flow control valves, providing insights into their features, benefits, and the key factors to consider when selecting the right one for your needs. In the dynamically evolving landscape of automation technologies, making informed decisions regarding pneumatic flow control valves ensures optimal performance and reliability in pneumatic systems.

Understanding Pneumatic Flow Control Valves: An Overview

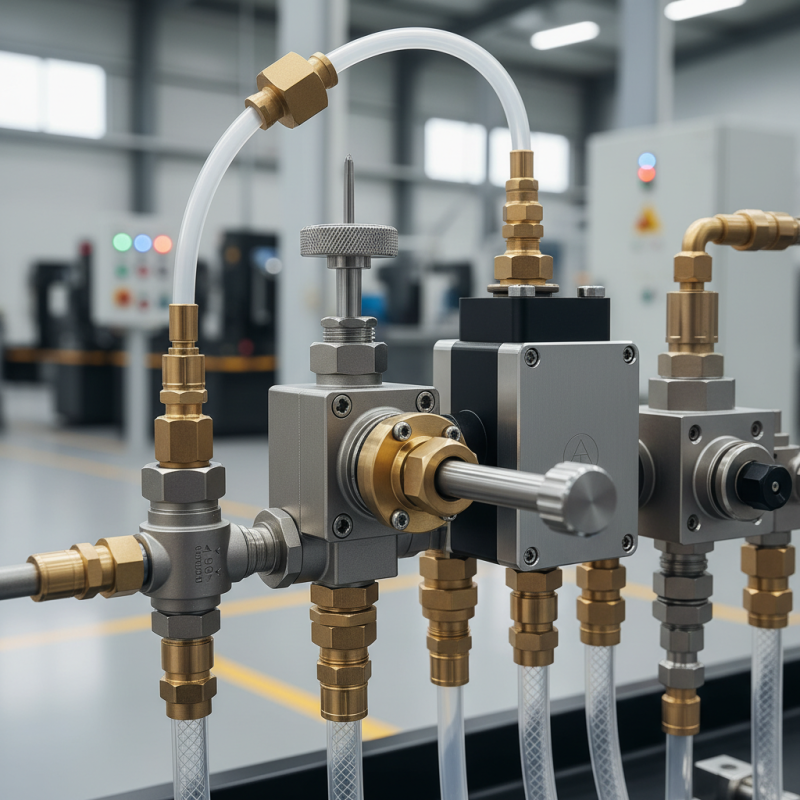

Pneumatic flow control valves play a crucial role in regulating the flow of compressed air in various industrial applications. These valves control the speed and direction of the air, thus impacting the performance and efficiency of pneumatic systems. Understanding the basic operation principles and types of flow control valves can significantly enhance the functionality of your equipment. Among the most common types are needle valves, which allow for precise flow adjustments, and flow control throttle valves, which maintain consistent flow rates, making them ideal for applications requiring steady motion.

When selecting a pneumatic flow control valve, consider the specific requirements of your system. Factors such as flow rate, pressure range, and installation space play pivotal roles in the decision-making process. Always ensure that the valve you choose is compatible with your existing setup to prevent operational issues.

Tips: Regular maintenance of your flow control valves is essential to ensure optimal performance. Check for leaks and signs of wear periodically. Additionally, consider consulting with a specialist if you are unsure about which type of valve will meet your needs, as they can provide valuable insights tailored to your system's specifications.

Top Pneumatic Flow Control Valve Types Explained

| Valve Type | Function | Advantages | Common Applications |

|---|---|---|---|

| Throttle Valves | Regulate flow rate | Simple design, cost-effective | General pneumatic systems |

| Flow Control Valves | Control the speed of actuators | Versatile, adjustable flow | Cylinders, pneumatic motors |

| Pressure Relief Valves | Prevent overpressure in systems | Safety mechanism, protects equipment | Hydraulic systems, pumps |

| Solenoid Valves | Electrically operated flow control | Quick response, reliable automation | Automation systems, machine controls |

| Check Valves | Allow flow in one direction | Prevents backflow, simple design | Fluid systems, pipelines |

Key Types of Pneumatic Flow Control Valves and Their Applications

Pneumatic flow control valves play a crucial role in regulating the flow of compressed air within various applications. Understanding the key types of these valves can significantly enhance system performance and efficiency.

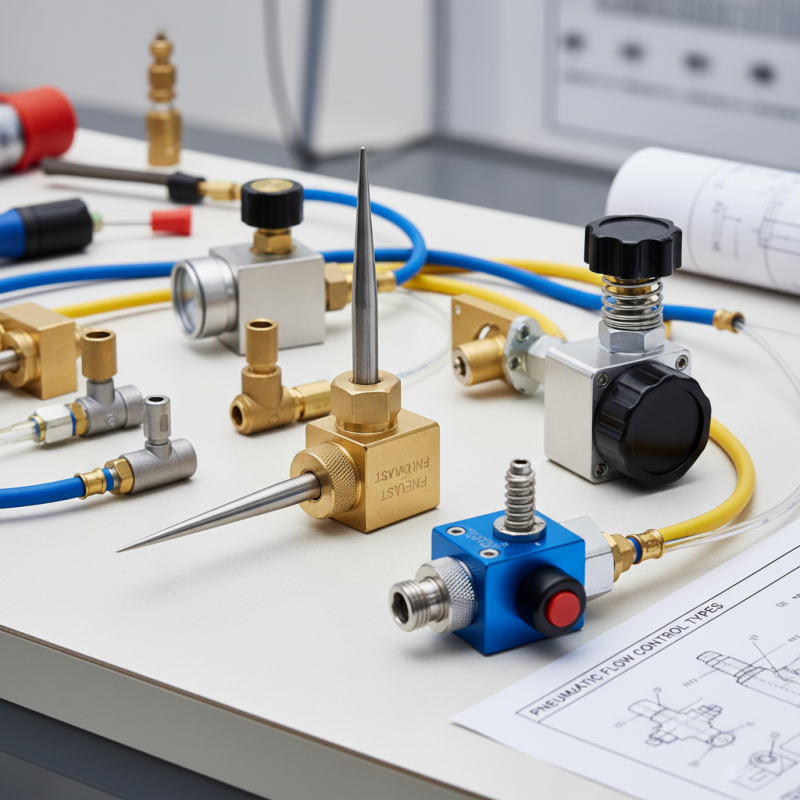

One prominent type is the needle valve, which provides precise flow adjustment through a tapered pin. This feature makes needle valves ideal for applications requiring fine-tuning, such as in laboratory settings or small-scale pneumatic systems.

Another essential type is the throttling valve, designed to maintain a steady flow rate despite variations in pressure. Throttling valves are commonly used in automation and robotic systems, where consistent airflow is necessary for the optimal functioning of actuators.

Lastly, the shuttle valve is widely utilized in circuits that need efficient switching between two sources of pneumatic pressure. This ensures that the system can seamlessly alternate between different air supplies, making shuttle valves invaluable in processes that demand flexibility.

By selecting the appropriate type of pneumatic flow control valve, users can tailor their systems to meet specific performance demands effectively.

Factors to Consider When Selecting a Pneumatic Flow Control Valve

When selecting a pneumatic flow control valve, several critical factors should be evaluated to ensure optimal performance in your specific application. One primary consideration is the valve's flow rate capacity, which must match the requirements of the system it will be used in. An incorrectly sized valve can lead to inefficiencies, affecting not only the process flow but also the overall energy consumption. According to industry reports, approximately 30% of pneumatic system failures are attributed to improper valve selection, emphasizing the importance of thorough assessment before making a choice.

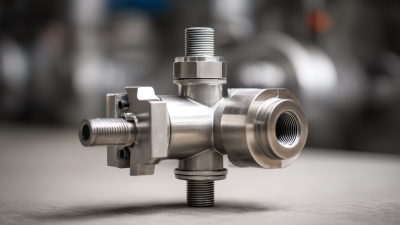

Another essential factor is the valve's construction material. Depending on the media flowing through, the chosen material must withstand the associated pressures and temperatures without degrading or affecting the system's integrity. For instance, if corrosive substances are involved, a valve with a robust, non-corrosive material is preferable to avoid premature failure. Additionally, consider the environmental conditions—such as temperature extremes and exposure to chemicals—which may necessitate specialized valve designs.

Tip: Always consult flow control valve performance charts and pressure drop calculations to determine the most suitable valve for your application. Regular maintenance and monitoring can also significantly enhance the lifespan and reliability of flow control valves, ensuring continuous operational efficiency.

Top Pneumatic Flow Control Valve Types

Comparative Analysis of Different Pneumatic Flow Control Valve Types

When selecting the appropriate pneumatic flow control valve, understanding the various types available is crucial for optimal system performance. The most common types include needle valves, which allow fine adjustments of flow, and flow control valves equipped with adjustable stops, which provide more straightforward flow regulation. According to a recent industry report, about 35% of flow control valve failures stem from improper selection or installation, underscoring the importance of choosing the right type for specific applications.

A comparative analysis reveals that proportional flow control valves offer notable advantages in applications requiring precise flow rates, while orifice flow control valves are ideal for simple, cost-effective solutions. An independent study highlighted that systems using proportional valves achieved a 15% boost in overall energy efficiency compared to those utilizing traditional valves, emphasizing how the right choice can impact both performance and operational costs.

Tips: When assessing flow control valves, always consider the specific flow requirements of your system, as well as any temperature and pressure ratings. It’s recommended to consult flow rate charts to determine the best valve size and type for your application. Additionally, maintenance plays a critical role; regular inspections can prevent failures and prolong the lifespan of your valves.

Best Practices for Installing and Maintaining Pneumatic Flow Control Valves

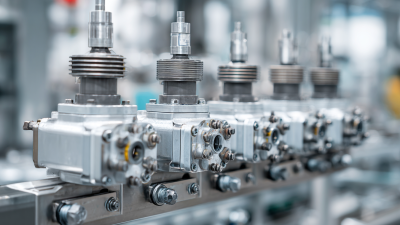

When it comes to the installation and maintenance of pneumatic flow control valves, following best practices is essential for ensuring optimal performance and longevity. A 2022 industry report highlights that improper installation can lead to a 20% reduction in system efficiency, underscoring the importance of adhering to manufacturer specifications and guidelines during the setup process. Proper alignment, securing connections, and ensuring the correct orientation of the flow designate the foundational steps in achieving reliable operation. Additionally, it is critical to select the appropriate valve type based on the specific application requirements—ranging from throttle valves for gradual flow regulation to quick exhaust valves for rapid exhaust scenarios.

Regular maintenance is equally important to prevent costly downtimes and prolong the lifespan of pneumatic flow control valves. A study noted that organizations that implemented routine inspections and servicing saw a 30% decrease in unscheduled outages. Practices such as cleaning the valve components, checking for leaks, and replacing worn seals can significantly improve performance. It's recommended to document maintenance activities, as this data can help in anticipating future issues and facilitate better management of maintenance schedules. Incorporating these best practices not only enhances the efficiency of pneumatic systems but also contributes to the overall safety and reliability of industrial operations.

Related Posts

-

2025 Top 5 Pneumatic Control Valves for Optimal Industrial Automation

-

Exploring the Future of Control Valves in Sustainable Industrial Applications

-

Why Understanding Pneumatic Flow Control Valves is Essential for Efficient Industrial Processes

-

Maximizing Operational Efficiency: The Role of Knife Gate Valves in Modern Industrial Applications

-

Top 5 Benefits of Using Pneumatic Butterfly Valves in Industrial Applications

-

Understanding the Benefits of Basket Strainers in Industrial Applications