Blog

Why Pneumatic Rotary Actuators Are Essential for Modern Automation

In the rapidly evolving landscape of modern automation, the significance of pneumatic rotary actuators can't be overstated. These devices are pivotal in enhancing efficiency, precision, and flexibility in various applications across industries such as manufacturing, automotive, and packaging. According to a recent report from Market Research Future, the global market for pneumatic actuators is expected to reach $6.4 billion by 2025, reflecting a compound annual growth rate (CAGR) of 5.5%. This growth is driven by the increasing demand for automation and the need for reliable and cost-effective solutions. Pneumatic rotary actuators play an essential role by providing smooth and controlled movement, making them indispensable in systems that require rapid cycles and high torque. As companies strive to optimize their processes and reduce downtime, the integration of these actuators is proving to be a key strategy in achieving competitive advantage in the automation realm.

The Role of Pneumatic Rotary Actuators in Boosting Automation Efficiency

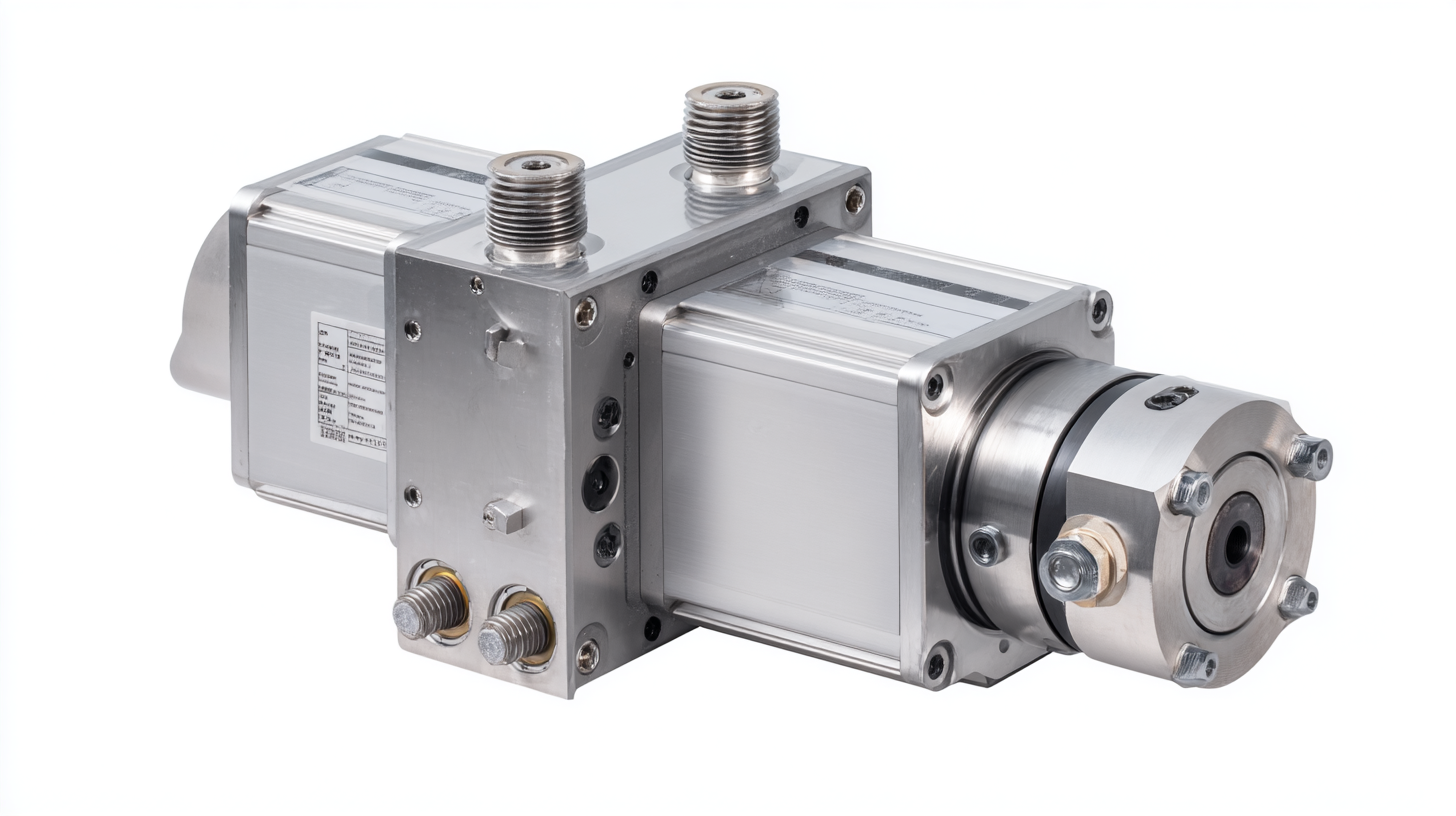

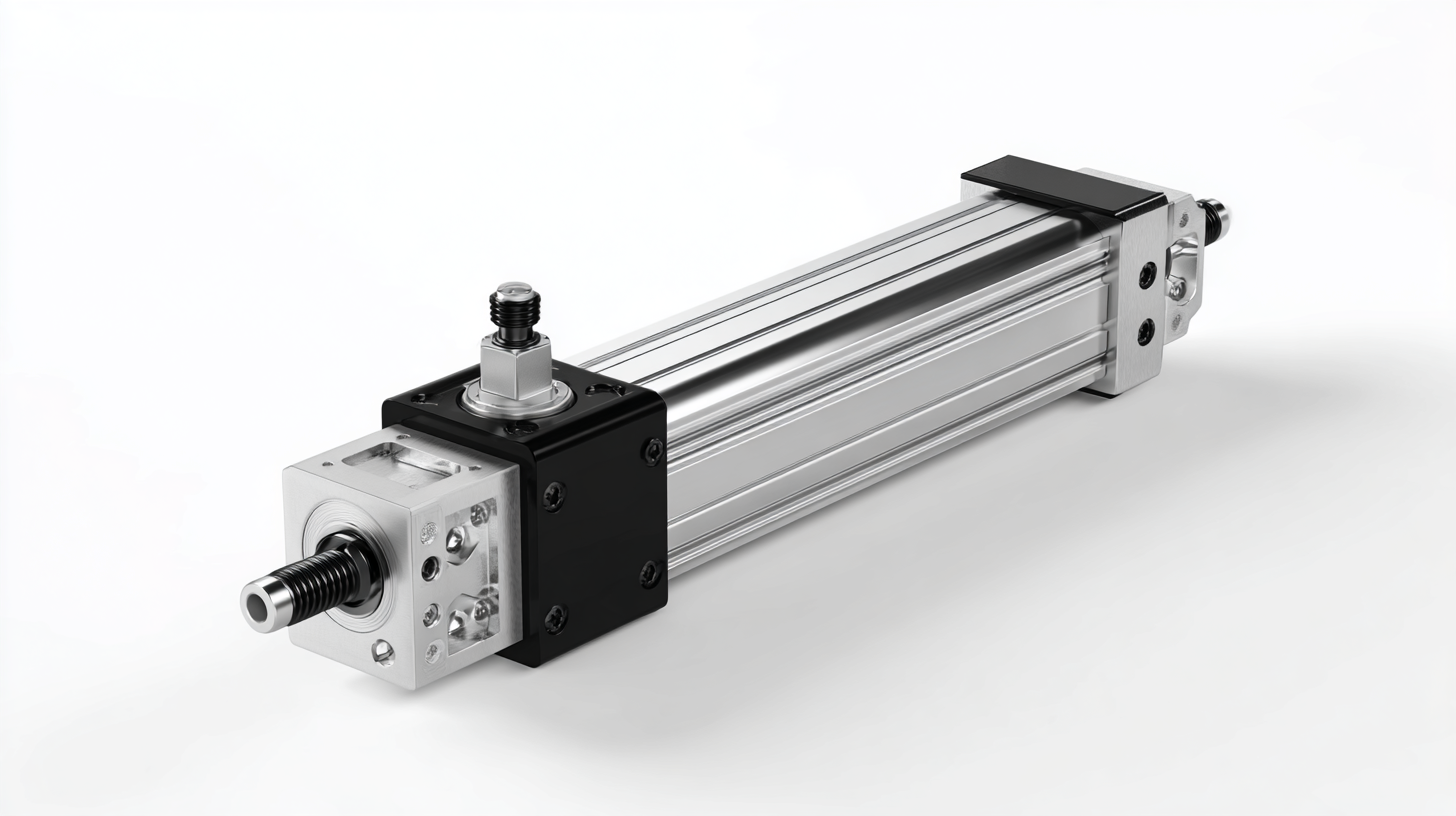

Pneumatic rotary actuators play a pivotal role in enhancing automation efficiency across various industries. By converting compressed air into rotational motion, these actuators facilitate rapid and precise control of machinery, significantly improving production rates. Their design allows for high torque output, making them ideal for tasks that require speed and strength, such as assembly lines, packaging machines, and robotic arms. As a result, industries that integrate pneumatic rotary actuators into their systems can benefit from reduced cycle times and increased throughput.

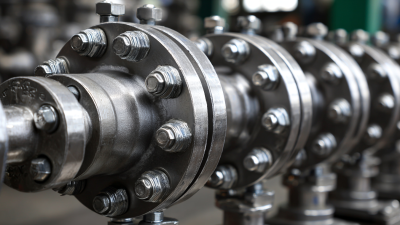

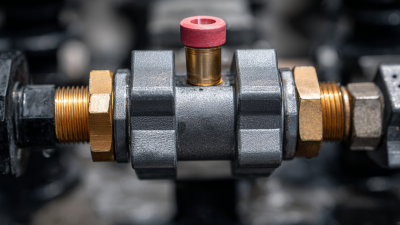

**Tips for Optimizing Automation with Pneumatic Rotary Actuators:** To fully harness the power of pneumatic rotary actuators, ensure that your compressed air supply is not only adequate but also clean and dry. Contaminants in the air can lead to actuator failure and reduced performance. Additionally, regular maintenance and timely replacement of seals and fittings can prevent leaks, maintaining efficiency and prolonging the lifespan of your actuators.

Moreover, it’s crucial to select the right actuator size and torque rating for your specific application. Oversized actuators can lead to unnecessary energy consumption, while undersized ones may struggle to meet operational demands. A careful assessment of your automation needs can guide you in choosing the optimal actuator that balances performance and energy efficiency.

Key Advantages of Pneumatic Rotary Actuators in Manufacturing Processes

Pneumatic rotary actuators play a critical role in modern manufacturing processes, offering several key advantages that enhance automation efficiency.

One significant benefit is their rapid response time. These actuators can achieve full rotation in a matter of seconds, allowing for quick cycle times in production lines.

In fast-paced environments where precision and speed are paramount, such efficiency directly translates to increased productivity.

Pneumatic rotary actuators play a critical role in modern manufacturing processes, offering several key advantages that enhance automation efficiency.

One significant benefit is their rapid response time. These actuators can achieve full rotation in a matter of seconds, allowing for quick cycle times in production lines.

In fast-paced environments where precision and speed are paramount, such efficiency directly translates to increased productivity.

Additionally, pneumatic rotary actuators require minimal maintenance compared to their electric counterparts. With fewer moving parts and a robust design, they are less prone to wear and tear, which reduces downtime and operational costs.

Their ability to handle harsh conditions, such as extreme temperatures and exposure to dust or moisture, makes them particularly suited for various industrial applications.

This reliability ensures that manufacturers can maintain consistent output and minimize interruptions in their operations, reinforcing the essential role of pneumatic rotary actuators in achieving streamlined and effective automation.

Data-Driven Insights: The Impact of Pneumatic Actuators on Downtime Reduction

Pneumatic rotary actuators play a vital role in modern automation by enhancing operational efficiency and minimizing downtime. Their ability to convert compressed air into rotational motion allows for swift and precise control in various industrial applications. By integrating these actuators into automated systems, businesses can significantly reduce the frequency of equipment failures, leading to increased productivity and lower maintenance costs. Data-driven insights indicate that companies utilizing pneumatic actuators experience a notable drop in unplanned downtime, which directly contributes to improved overall performance.

Tips for maximizing the benefits of pneumatic rotary actuators include regular maintenance checks to ensure optimal functioning. Monitor air quality and pressure levels, as contaminants or fluctuations can affect performance. Additionally, investing in training for personnel can enhance the understanding of actuator capabilities, leading to better troubleshooting and faster response times during equipment malfunctions. This proactive approach not only supports the longevity of the actuators but also sustains the efficiency of the entire automation system.

Selecting the Right Pneumatic Rotary Actuator for Your Automation Needs

When selecting the right pneumatic rotary actuator for modern automation applications, it's vital to consider the specific requirements of your operations. The ISA-96 series of standards provides essential guidelines for the specification, design, and testing of valve actuators and their accessories, which can greatly influence actuator choice. Key factors to assess include the application environment, the required precision, and the load capacity that the actuator must handle.

The demand for efficient automation solutions is growing across various industries, including manufacturing and agriculture. Pneumatic technologies remain a reliable choice for applications requiring speed and force, such as pick-and-place operations. As companies increasingly focus on Industry 4.0 initiatives, the integration of pneumatic rotary actuators in automated systems enhances not only speed and efficiency but also flexibility in operations. Ensuring the right actuator is selected can facilitate seamless automation and significantly improve productivity.

Future Trends: Innovations in Pneumatic Rotary Actuator Technology

Innovations in pneumatic rotary actuator technology are significantly shaping the future of automation. According to a recent report by MarketsandMarkets, the global pneumatic actuator market is projected to reach USD 13.3 billion by 2026, growing at a CAGR of 5.2%. This growth is driven by advancements in materials and design that enhance the efficiency and reliability of these devices. The integration of smart sensors and IoT connectivity into pneumatic rotary actuators allows for real-time monitoring and predictive maintenance, leading to decreased downtime and improved operational efficiency.

Another noteworthy trend is the ongoing miniaturization and increased power density of pneumatic rotary actuators. Industry research indicates that compact actuators can now deliver enhanced performance in confined spaces, catering to the demands of modern, space-constrained manufacturing environments. This adaptability not only helps manufacturers reduce their footprint but also contributes to energy savings and lower operational costs. As the demand for automation continues to surge across various industries, the innovations in pneumatic rotary actuators will play a crucial role in enabling smarter, more efficient automated systems.

Why Pneumatic Rotary Actuators Are Essential for Modern Automation - Future Trends: Innovations in Pneumatic Rotary Actuator Technology

| Feature | Current Trend | Future Innovation | Impact on Automation |

|---|---|---|---|

| Efficiency | High-speed operation | Smart sensors integration | Improved production rates |

| Size | Compact designs | Nano-actuators | Reduced space requirements |

| Control | Manual and electronic controls | AI-driven adaptive control | Enhanced precision in operations |

| Maintenance | Regular operational checks | Predictive maintenance using IoT | Reduced downtime |

| Energy Consumption | Optimized air usage | Energy-efficient designs | Lower operational costs |