Blog

Revolutionizing Industrial Automation with Cutting-Edge Pneumatic Valve Actuators

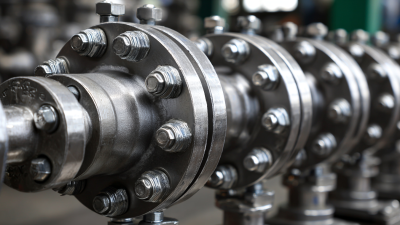

In the realm of industrial automation, the importance of precision and efficiency cannot be overstated. The integration of pneumatic valve actuators has emerged as a transformative solution, streamlining processes across various sectors. According to a recent industry report by MarketsandMarkets, the global pneumatic actuator market is expected to reach USD 6.5 billion by 2025, growing at a CAGR of 5.2% from 2020. This surge is driven by the increasing demand for automation and greater efficiency in manufacturing operations. Pneumatic valve actuators, known for their reliability and responsiveness, play a crucial role in controlling fluid movement and ensuring optimal performance in complex systems. As industries continually seek ways to enhance productivity and reduce operational costs, the adoption of advanced pneumatic valve actuators stands at the forefront of this revolution in industrial automation.

Understanding the Role of Pneumatic Valve Actuators in Modern Industry

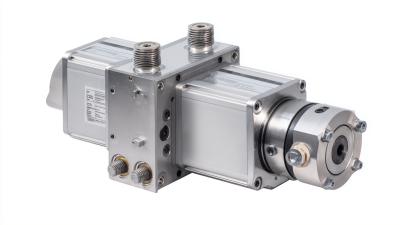

Pneumatic valve actuators play a crucial role in modern industrial automation by enhancing efficiency and reliability in system operations. As reported by the International Society of Automation, over 30% of industrial processes now utilize pneumatic systems, highlighting their significance in various sectors, including manufacturing, oil and gas, and chemical processing. These actuators convert compressed air into mechanical motion, enabling precise control of valve operations. This functionality is essential for managing the flow of gases and liquids, ensuring safety and optimizing resource utilization.

Pneumatic valve actuators play a crucial role in modern industrial automation by enhancing efficiency and reliability in system operations. As reported by the International Society of Automation, over 30% of industrial processes now utilize pneumatic systems, highlighting their significance in various sectors, including manufacturing, oil and gas, and chemical processing. These actuators convert compressed air into mechanical motion, enabling precise control of valve operations. This functionality is essential for managing the flow of gases and liquids, ensuring safety and optimizing resource utilization.

The demand for pneumatic valve actuators continues to grow, driven by the need for faster response times and reduced downtime. According to a Market Research Future report, the global pneumatic actuators market is projected to reach $9.76 billion by 2025, expanding at a compound annual growth rate (CAGR) of 6.3%. This growth underscores the pivot towards automation and the essential role that pneumatic valve actuators play in streamlining processes. Companies are increasingly adopting these technologies to achieve greater productivity while minimizing operational costs, thereby revolutionizing industrial workflows in an increasingly competitive landscape.

Key Features to Look for When Choosing Pneumatic Valve Actuators

When selecting pneumatic valve actuators for industrial automation, several key features are essential to ensure optimal performance and reliability. First and foremost, the actuator's response time is crucial; a quicker response leads to more efficient process control. Look for models that are engineered for rapid actuation, enabling seamless integration into high-speed operations.

When selecting pneumatic valve actuators for industrial automation, several key features are essential to ensure optimal performance and reliability. First and foremost, the actuator's response time is crucial; a quicker response leads to more efficient process control. Look for models that are engineered for rapid actuation, enabling seamless integration into high-speed operations.

Another important aspect is the actuator's compatibility with various valve types and sizes. Versatile actuators can accommodate different applications, reducing the need for multiple actuator types within a facility. Additionally, examine the materials used in the construction of the actuator; corrosion-resistant materials enhance durability, especially in harsh industrial environments.

Finally, the control options available are vital for flexibility in automation. Many modern pneumatic valve actuators come equipped with advanced features such as digital control interfaces, allowing for precise adjustments and real-time monitoring. This technological integration not only improves operational efficiency but also supports predictive maintenance, reducing downtime and associated costs in industrial settings.

Step-by-Step Guide to Installing Pneumatic Valve Actuators in Your System

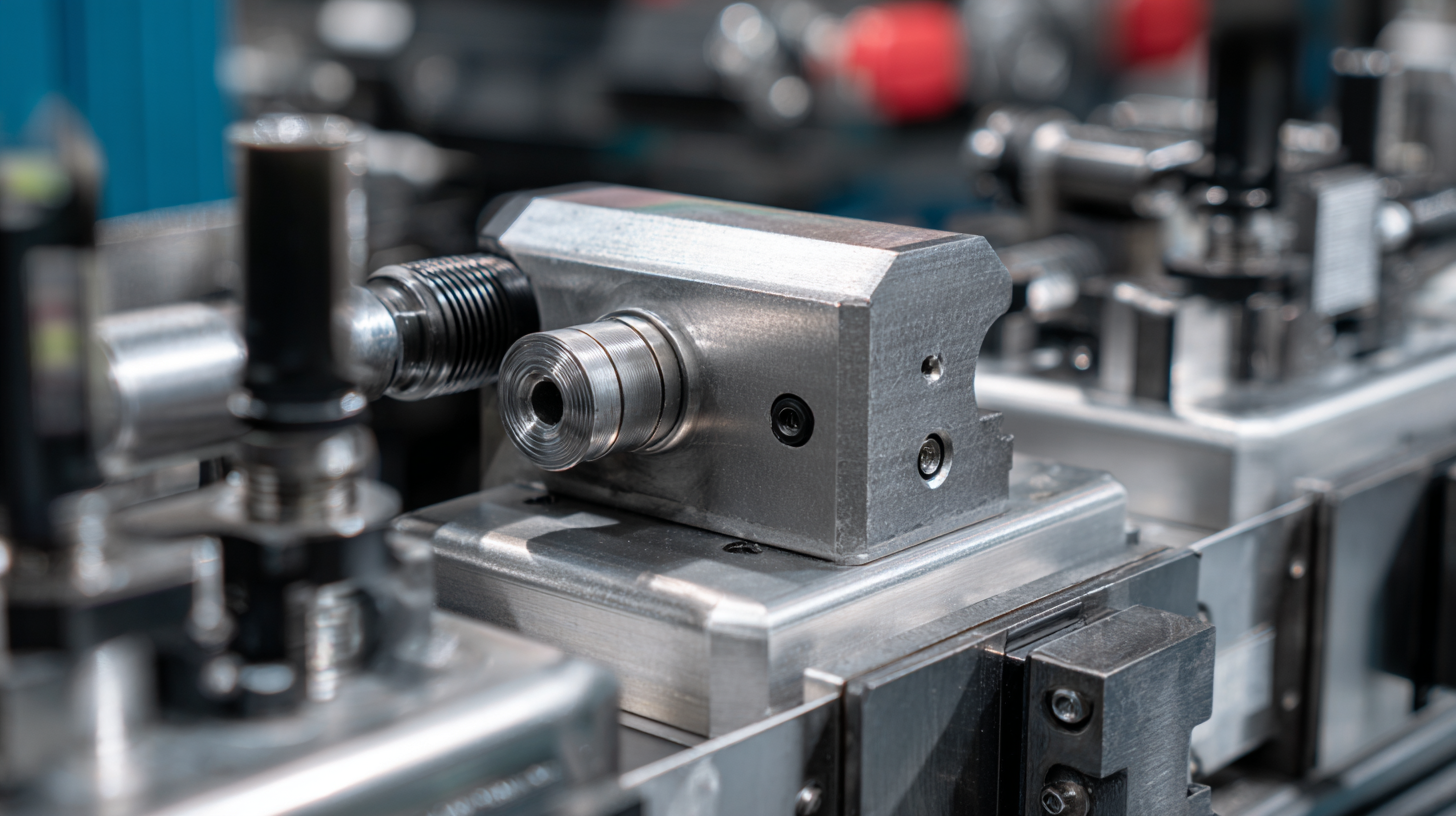

Installing pneumatic valve actuators in your industrial system can be a transformative process that enhances efficiency and reliability. Begin by selecting the appropriate actuator for your specific application, taking into account factors such as pressure requirements, actuator size, and the type of valve being used. Once you have the right actuator, prepare your workspace by ensuring all tools and components are readily available. Safety should be a priority, so make sure to disconnect any pneumatic supply before starting installation.

The installation process typically starts with mounting the actuator onto the valve. Align the actuator with the valve base, ensuring that the drive shaft is correctly positioned. Use the provided mounting hardware to secure it tightly, adhering to the manufacturer's specifications. Next, connect the pneumatic lines, ensuring there are no leaks by performing a pressure test. After securing all connections, check that the actuator moves freely without obstruction. Finally, calibrate the actuator settings as per your system requirements to ensure optimal performance. By following these steps, you can successfully integrate pneumatic valve actuators into your industrial automation system, paving the way for increased operational efficiency.

Troubleshooting Common Issues with Pneumatic Valve Actuators

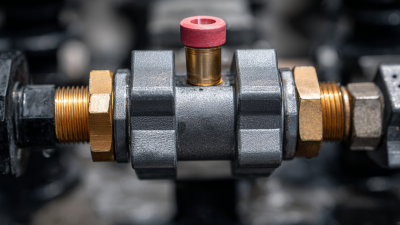

Pneumatic valve actuators are critical components in industrial automation, but they can encounter several common issues that may disrupt operations. One prevalent problem is leakage, which can significantly impact efficiency. According to a report by the International Society of Automation, leakage can cause a 20-30% loss in system efficiency, driving up operational costs. Regular maintenance and inspection schedules are essential to identify wear on seals and gaskets that often contribute to this issue.

Another frequent challenge is actuator failure due to insufficient air supply or pressure fluctuations. Research from the Pneumatics and Hydraulics Group indicates that up to 15% of actuator failures in the field are attributed to these factors. Implementing pressure regulation and ensuring that the piping system is free from obstructions can mitigate this risk. Additionally, it's crucial for operators to be trained in troubleshooting techniques to quickly diagnose and resolve these issues, thereby minimizing downtime and maintaining productivity in automated processes.

Future Trends in Pneumatic Valve Technology for Enhanced Automation

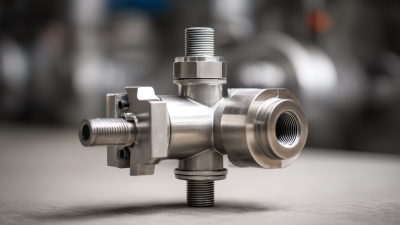

The future of pneumatic valve technology is poised for significant advancements as industries increasingly adopt automation solutions to enhance efficiency and productivity. The market for pneumatic low flow control valves is projected to grow from $120 million in 2022 to an estimated $180 million by 2030, showcasing a compound annual growth rate (CAGR) of 6.9% from 2024 to 2030. This growth indicates a robust demand for more sophisticated valve systems that can cater to specific operational needs within various industrial applications.

As companies seek to optimize their processes, the integration of cutting-edge pneumatic valve actuators becomes essential. These innovative actuators not only improve response times and precision in valve operations but also support the trend towards more sustainable and energy-efficient manufacturing practices. With the increasing focus on automation, the development of specialized valves, such as mixproof valves suited for demanding environments, will likely drive market expansion and promote the evolution of pneumatic valve technologies in future industrial automation systems.

Related Posts

-

Exploring Air Actuator Innovations at the 138th Canton Fair 2025 in China

-

Why Pneumatic Rotary Actuators Are Essential for Modern Automation

-

Exploring Pneumatic Rotary Actuator Innovations at 2025 China Import and Export Fair

-

How to Choose the Right Pneumatic Valve for Your Industrial Application

-

Why Understanding Pneumatic Flow Control Valves is Essential for Efficient Industrial Processes

-

How to Select the Best Butterfly Valve Type for Your Industrial Needs