Blog

How to Select the Best Butterfly Valve Type for Your Industrial Needs

In the industrial sector, the selection of the appropriate butterfly valve types is crucial for ensuring efficient fluid control and system reliability. According to a report by Markets and Markets, the global butterfly valve market is projected to reach USD 8.6 billion by 2025, growing at a CAGR of 6.2% from 2020 to 2025. This growth is driven by the increasing demand for automation in various industries such as oil and gas, water and wastewater management, and power generation. Given the multitude of butterfly valve types available, each with distinct features and applications, it is essential to understand the specific needs of your operation. Factors such as fluid characteristics, pressure requirements, and pipe size must be considered to select the most suitable valve type for optimal performance and longevity. In this guide, we will explore the different butterfly valve types, their advantages, and how to effectively choose the right one for your industrial applications.

Understanding the Different Types of Butterfly Valves Available in the Market

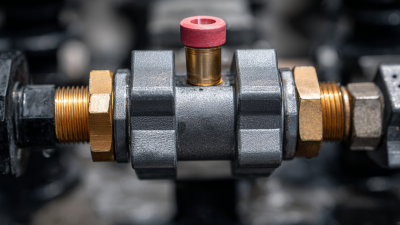

When selecting the best butterfly valve type for industrial applications, it is essential to understand the various options available in the market. Butterfly valves are widely used due to their simple design, low cost, and versatility in handling different types of fluids. Key types include the resilient seated butterfly valve, which is suitable for gas and water applications, and the high-performance butterfly valve, ideal for more demanding industrial environments. Each type has unique features that cater to specific needs, such as temperature, pressure rating, and fluid characteristics.

Recent market developments indicate a strong growth trajectory for the butterfly valve segment, driven largely by advancements in manufacturing techniques and materials, as well as increasing demand in sectors like oil and gas. The introduction of innovative designs, such as flanged butterfly valves, enhances performance and reliability in high-pressure systems. As industries continue to prioritize efficiency and durability, understanding the distinct features of each butterfly valve type will be crucial for making informed selections that meet operational requirements.

How to Select the Best Butterfly Valve Type for Your Industrial Needs

| Valve Type | Application | Pressure Rating | Materials | Temperature Range |

|---|---|---|---|---|

| Wafer Butterfly Valve | Water treatment, HVAC | 150 PSI | Cast Iron, Stainless Steel | -20°F to 350°F |

| Lug Butterfly Valve | Oil and gas, Chemical processing | 200 PSI | PVC, CPVC | -40°F to 140°F |

| Double Offset Butterfly Valve | High-performance applications, Steam service | 300 PSI | Carbon Steel, Stainless Steel | -30°F to 500°F |

| Triple Offset Butterfly Valve | Cryogenic service, High pressure | 600 PSI | Alloy Steel, AISI | -320°F to 850°F |

| Electric Butterfly Valve | Automated systems, Water distribution | 150 PSI | Aluminum, Plastic | -10°F to 180°F |

Key Factors Influencing the Selection of Butterfly Valves for Industrial Applications

When selecting the best butterfly valve type for industrial applications, several key factors come into play. The specific application requirements, such as the type of fluid being controlled, temperature, pressure, and flow characteristics, are crucial in guiding the choice. For instance, different materials are suited for various fluids—corrosive fluids may necessitate valves made from stainless steel or special alloys, while non-corrosive applications might allow for more cost-effective options like plastic or cast iron.

Moreover, the performance characteristics of the valve are essential. Considerations include the valve size, actuation method (manual, electric, or pneumatic), and whether a double-offset or triple-offset design is required for tight sealing under pressure. Each design variation offers different sealing capabilities and operating efficiencies, which can significantly impact the overall effectiveness and longevity of the valve in a specific industrial environment. By thoroughly evaluating these factors, businesses can ensure they select the most suitable butterfly valve to meet their operational demands efficiently.

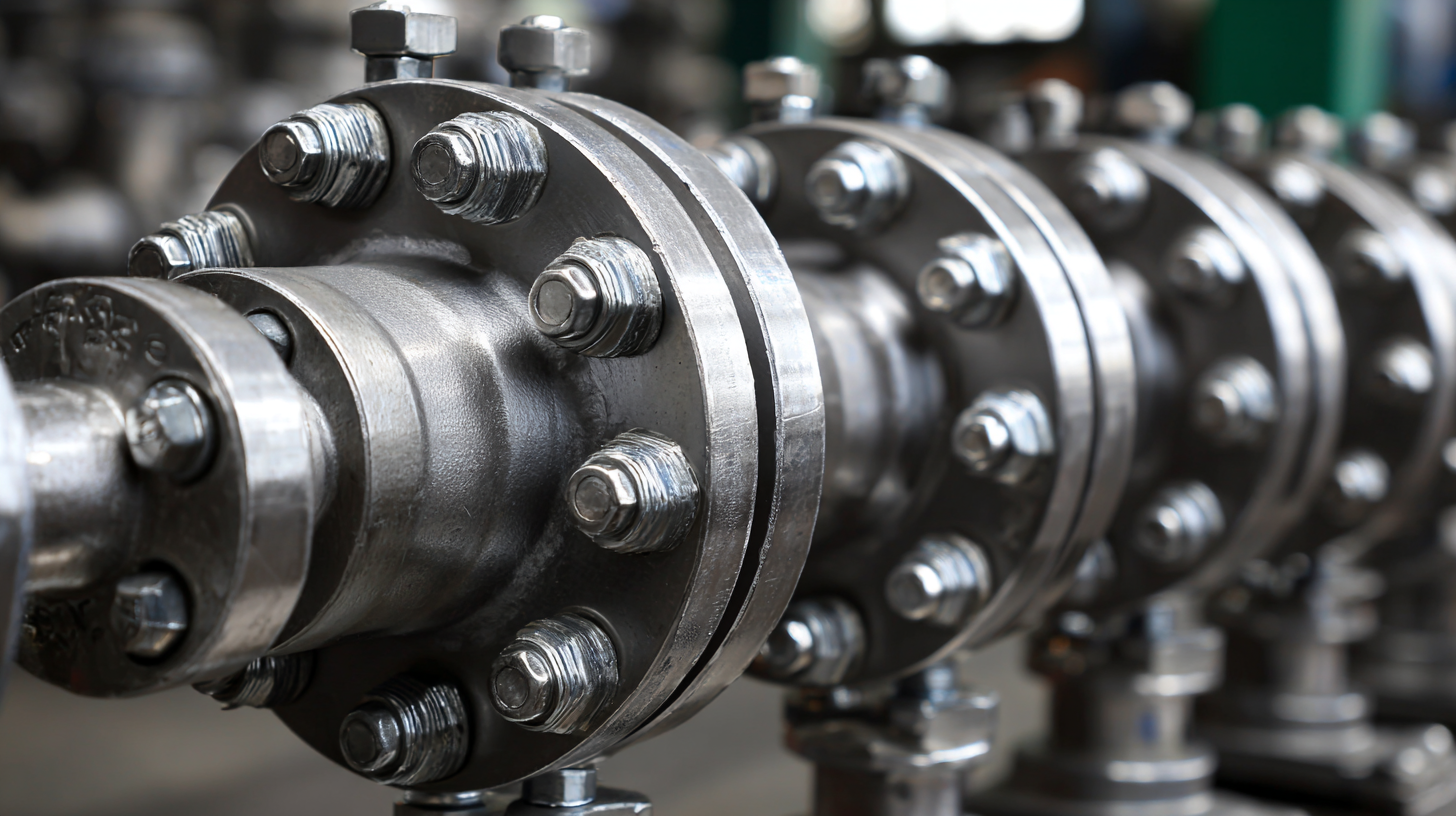

Comparing Materials and Construction for Durability and Performance in Butterfly Valves

When selecting the best butterfly valve for industrial applications, comparing materials and construction is essential for ensuring durability and performance. Butterfly valves typically come in various materials such as cast iron, stainless steel, and ductile iron, each offering distinct advantages. For instance, stainless steel valves are ideal for applications involving corrosive fluids due to their resistance to oxidation and pitting. Conversely, cast iron valves are often favored for their cost-effectiveness and ability to withstand high-pressure environments, making them suitable for many general-purpose applications.

The construction of a butterfly valve also plays a critical role in its functionality. A valve with a resilient seat can provide a tighter seal and better performance in high-flow conditions. Additionally, the design of the shaft and disc can influence the torque requirements for operation; a well-engineered butterfly valve will optimize flow control while minimizing energy loss. Therefore, understanding the operational environment and selecting the right materials and construction methods is vital for enhancing the lifespan and reliability of butterfly valves in any industrial setting.

Evaluating Size and Configuration Requirements for Effective Valve Operation

When selecting the best butterfly valve type for industrial applications, evaluating size and configuration requirements is crucial for ensuring effective valve operation. According to the Industrial Valve Market Report 2022, the global demand for butterfly valves is expected to grow at a CAGR of 5.6% from 2023 to 2030. This growth is driven largely by industries such as oil and gas, water treatment, and power generation, where precise control of flow is essential.

The first step in the evaluation process is determining the appropriate size. The American National Standards Institute (ANSI) standards suggest that the diameter of the butterfly valve should match the pipe diameter for optimal flow characteristics and minimal pressure loss. Additionally, it is essential to consider the configuration of the piping system. For instance, valves should be strategically placed to minimize turbulence and ensure uniform flow distribution, thereby enhancing system efficiency. A recent study by the Valve Manufacturers Association indicated that mismatched valve sizes could lead to energy losses of up to 20%, highlighting the importance of careful selection based on system requirements. By aligning valve size and configuration with operational needs, industries can achieve improved reliability and performance in their fluid control systems.

Assessing Cost-Effectiveness and Maintenance Needs of Butterfly Valves for Long-Term Use

When selecting a butterfly valve for industrial applications, evaluating the cost-effectiveness and maintenance needs is crucial for long-term sustainability. According to a report by the Valve Manufacturers Association, butterfly valves typically have lower initial costs compared to gate and globe valves, making them an attractive option for budget-conscious projects. Additionally, their simpler design often results in reduced maintenance needs, with many units requiring minimal upkeep compared to other valve types. For industries with high volume and routine operations, this can lead to significant cost savings over time.

Tips for choosing the right butterfly valve include assessing the fluid characteristics in your system. Consider factors such as temperature, pressure, and whether the fluid is corrosive or abrasive. Selecting the appropriate material can boost durability and efficiency, especially in challenging environments. Furthermore, investing in automated systems can streamline operations and reduce manual inspection needs, ensuring consistent performance over the valve's lifecycle.

Another important consideration is the valve’s position in your piping system. The installation location can directly affect maintenance access, as regularly accessible valves are easier to service or replace. Reports from industry studies emphasize that proactive planning for maintenance access can save both time and money in the long run, enhancing operational efficiency and reliability in your industrial processes.