Blog

Understanding the Role of Spring Check Valves in Modern Fluid Systems: A Comprehensive Guide

In the rapidly evolving landscape of modern fluid systems, the spring check valve has emerged as a pivotal component, ensuring efficient flow control and preventing backflow in various applications. According to a report by MarketsandMarkets, the global check valve market is projected to reach USD 10.8 billion by 2026, driven by the increasing demand for automation and enhanced process efficiency in industries such as water treatment, oil and gas, and chemical manufacturing. The design and functionality of the spring check valve allow it to operate automatically, responding to changes in flow direction while minimizing pressure loss. This guide delves into the critical role of spring check valves, highlighting their applications, benefits, and recent technological advancements that are shaping their efficiency and reliability in fluid systems today.

The Functionality of Spring Check Valves in Various Fluid Systems

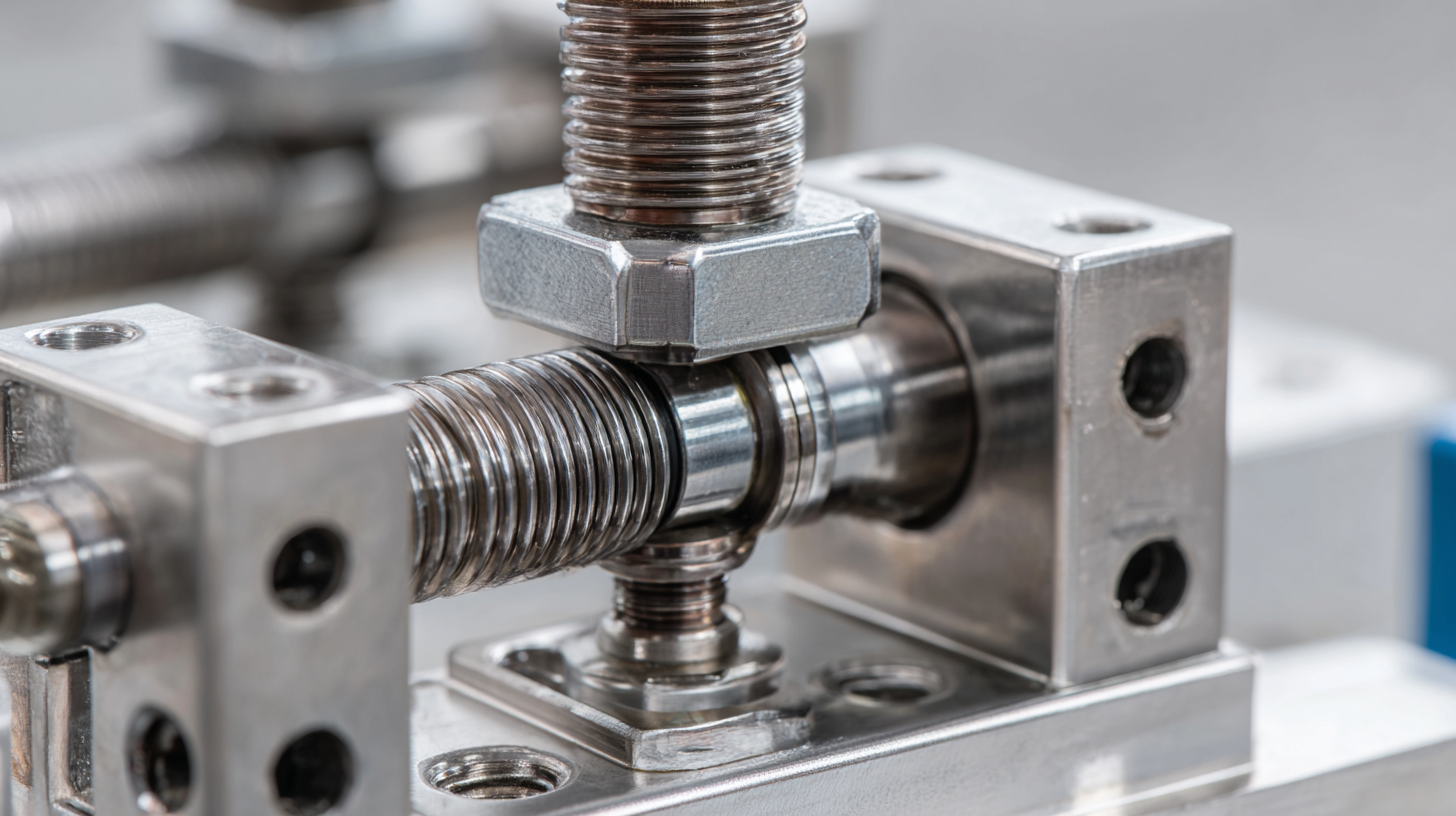

Spring check valves play a critical role in various fluid systems by ensuring unidirectional flow and preventing backflow. These valves are designed with a spring mechanism that allows fluid to flow in one direction while automatically closing when the flow attempts to reverse. This functionality is essential in maintaining system integrity, preventing contamination, and protecting equipment from potential damage caused by backpressure.

In applications ranging from water treatment to industrial processes, spring check valves are integral to system efficiency. They are commonly found in piping systems that transport liquids, ensuring a stable flow while safeguarding pumps and other components. When the fluid tries to flow backward, the spring closes the valve, allowing the system to operate smoothly without interruptions. Furthermore, their compact design and versatility make them suitable for a wide range of fluid types, including aggressive chemicals and viscous substances, highlighting their importance in modern engineering applications.

Understanding the Role of Spring Check Valves in Modern Fluid Systems

| Fluid System Type | Application | Material | Pressure Rating (psi) | Temperature Range (°F) |

|---|---|---|---|---|

| Water Supply Systems | Prevent backflow in sprinkler systems | Brass | 150 | 32 to 180 |

| HVAC Systems | Regulate flow in heating and cooling processes | Plastic | 250 | 40 to 200 |

| Pneumatic Systems | Control airflow in machinery | Aluminum | 200 | -10 to 120 |

| Chemical Processing | Prevent backflow of corrosive liquids | Stainless Steel | 300 | -20 to 300 |

| Food and Beverage | Ensure safety and hygiene in processing | Hygienic Stainless Steel | 150 | 32 to 250 |

Top 5 Benefits of Incorporating Spring Check Valves in Modern Applications

Spring check valves are essential components in modern fluid systems, offering significant advantages across various applications. One of the top benefits is their ability to prevent backflow, ensuring consistent flow direction and safeguarding system integrity. According to a recent industry report from the Fluid Power & Control group, the incorporation of check valves can reduce operational losses by over 15%, highlighting their efficiency in maintaining fluid movement without reverse leakage.

Another compelling advantage is related to reliability and durability under stress. Recent findings in valve spring stress testing indicate that these components endure fatigue from repeated compression and expansion. The precise design and construction of spring check valves contribute to their resilience, allowing them to maintain operational efficiency over extended periods. Data from the Industrial Valve Market Analysis suggests that properly designed spring valves have a lifespan that can exceed 10 years, significantly reducing maintenance costs and downtime, which is critical for sectors employing high-pressure and high-flow applications. These attributes underscore the importance of integrating spring check valves into fluid systems for enhanced performance and longevity.

Industry Statistics: Efficiency Gains from Using Spring Check Valves

The introduction of spring check valves in fluid systems has significantly improved operational efficiency across various industries. These valves play a crucial role in preventing backflow, thereby ensuring smooth fluid transfer and protecting equipment from potential damage. Recent industry reports indicate that the market for boiler feed check valves alone is projected to reach USD 2,055 million by 2032, reflecting a compound annual growth rate of 5.5%. This growth underscores the rising recognition of the functional benefits that spring check valves bring to industrial boiler systems and steam generation processes.

Incorporating failure mode and effects analysis (FMEA) into the design of automotive components, including leaf springs, highlights the importance of reliability and risk management in valve applications. By meticulously analyzing potential failures, industries can refine their designs and manufacturing processes, thereby enhancing the overall efficiency and safety of fluid systems. The interplay between innovative design and the utilization of spring check valves indicates a broader industry trend toward adopting advanced technologies that optimize performance and longevity. As industries continue to embrace these components, the quantifiable efficiency gains will likely foster further advancements in fluid management systems.

Efficiency Gains from Using Spring Check Valves

This chart demonstrates the efficiency gains observed in various fluid systems when employing spring check valves. The data reflects improvements in system performance, energy savings, and operational reliability.

Comparative Analysis of Spring Check Valves vs. Other Check Valve Types

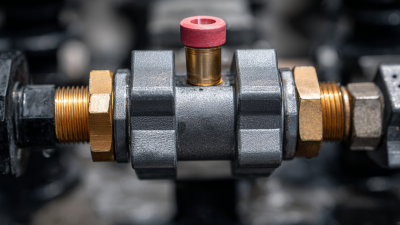

Spring check valves play a crucial role in modern fluid systems, providing a reliable solution for preventing backflow. Unlike other types of check valves, such as swing or diaphragm check valves, spring check valves utilize a spring mechanism to ensure that the valve closes promptly when the flow reverses. According to a report by the Global Market Insights, the spring check valve market is anticipated to witness significant growth, driven by the increasing demand for efficient fluid management systems across various industries. This growth is supported by its ability to operate in a compact design, making it suitable for space-constrained applications.

When comparing spring check valves to other check valve types, it is essential to consider their operational effectiveness and installation flexibility. For instance, the 2022 Valve Manufacturers Association report indicates that spring check valves have a higher closure speed, reducing the potential for water hammer and ensuring a quieter operation. Conversely, swing check valves may require more space and can suffer from delayed closure, potentially compromising system integrity in high-pressure environments. On the whole, the selection of the appropriate check valve type hinges on the specific requirements of the fluid system, where spring check valves often emerge as the more efficient choice for maintaining fluid flow and preventing backflow effectively.

Maintenance Best Practices for Optimal Performance of Spring Check Valves

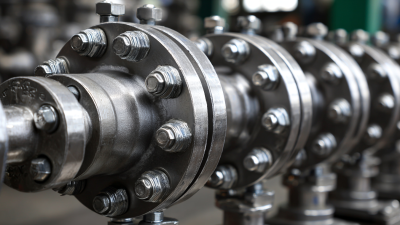

Maintenance of spring check valves is essential for ensuring optimal performance in fluid systems. Regular inspections should be part of any maintenance routine, focusing on detecting signs of wear and tear. It's important to examine the valve body, spring mechanism, and sealing surfaces for any corrosion or damage. A thorough check can help identify issues before they lead to significant failures, allowing for timely repairs or replacements.

Another best practice involves ensuring that the installation of the spring check valves is correct. Following the manufacturer's specifications for orientation and torque can greatly enhance the valve's efficiency. Operators should also monitor the operating conditions, as extreme temperatures or fluctuating pressures can affect the valve's performance. Keeping detailed records of maintenance activities and valve conditions is crucial, as it provides a clear history and aids in decision-making regarding replacements or upgrades, ensuring that the fluid systems operate smoothly and reliably.

Related Posts

-

Exploring Pneumatic Rotary Actuator Innovations at 2025 China Import and Export Fair

-

How to Choose the Right Pneumatic Valve for Your Industrial Application

-

Exploring Duplex Strainer Innovations at the 138th Canton Fair in 2025

-

How to Select the Best Butterfly Valve Type for Your Industrial Needs

-

Exploring the Future of Basket Strainers at the 138th Canton Fair 2025 in China

-

How to Choose the Right Basket Strainers for Your Industrial Needs