Blog

Top 10 Globe Valves Types and Their Applications in Industrial Systems You Should Know

In the realm of industrial systems, globe valves play a pivotal role due to their ability to manage flow control comprehensively. According to industry expert Dr. Emily Carter, a renowned authority on valve technology, "Globe valves are indispensable for any system requiring precise flow regulation, making them a cornerstone of successful industrial operations." This statement underscores the importance of understanding the different types of globe valves and their specific applications.

As industries continue to evolve, the demand for efficient and reliable flow management has never been greater. With various globe valve designs available, each tailored for specific operational requirements, choosing the right type can significantly enhance performance and reliability. In this article, we will delve into the top 10 globe valve types, exploring their unique characteristics, uses, and advantages within industrial systems. Understanding these aspects is crucial for engineers and operators seeking to optimize their processes and ensure seamless operation.

Overview of Globe Valve Types and Their Unique Features

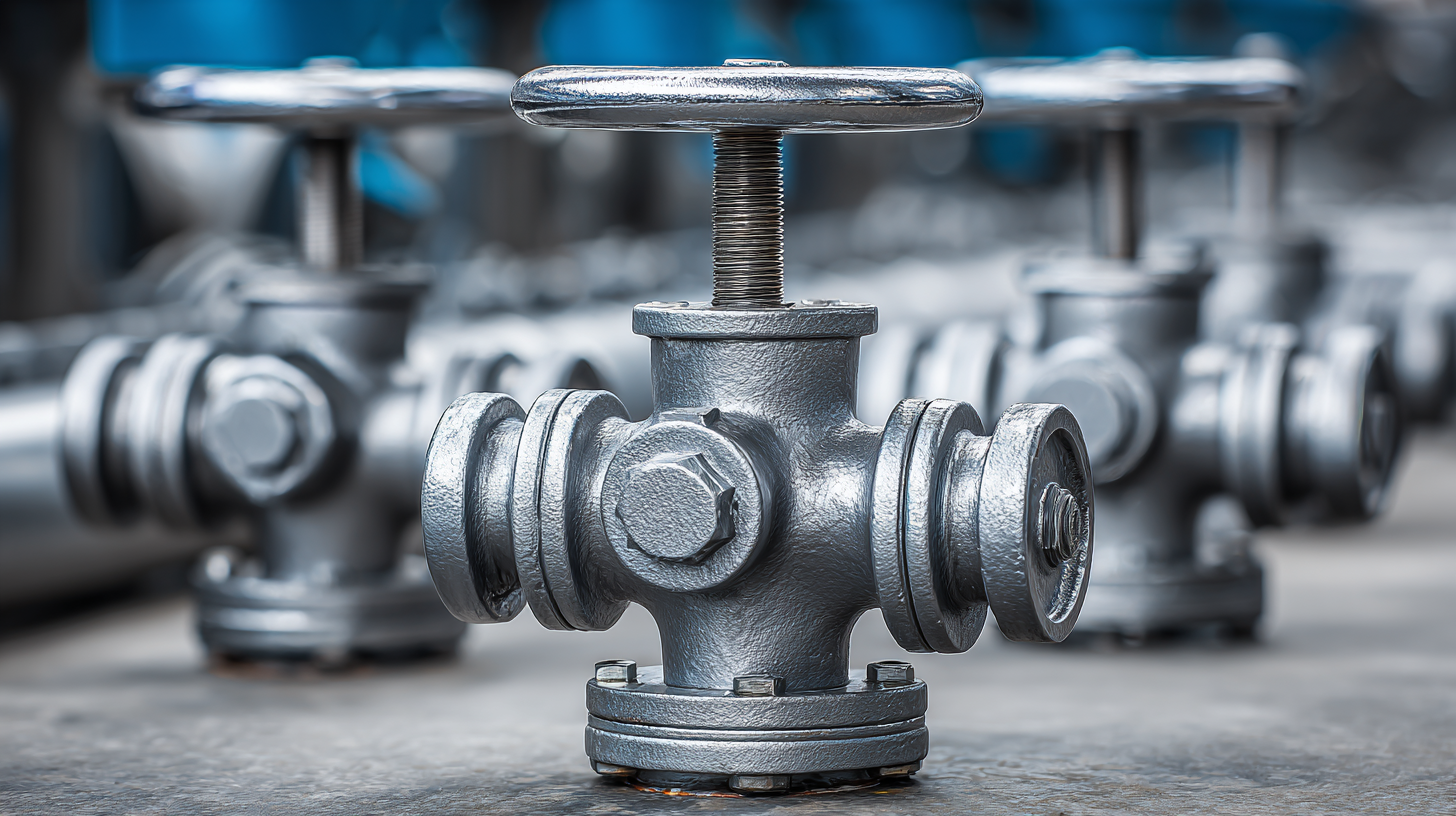

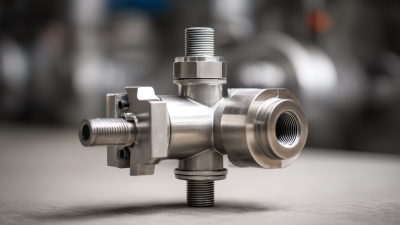

Globe valves are essential components in industrial systems, known for their excellent flow control capabilities. There are various types of globe valves, each with unique features tailored for specific applications. The most common types include standard globe valves, angle globe valves, and Y-pattern globe valves. Standard globe valves offer straightforward designs ideal for throttling services, while angle globe valves are well-suited for systems with tight spaces. Y-pattern globe valves, known for their superior flow characteristics, are often used in high-pressure scenarios.

As the industrial valve market continues its upward trajectory, projected to reach USD 128.2 billion by 2035, understanding the unique features of each valve type is paramount. Reports indicate that the demand for globe valves is particularly driven by their reliability and efficiency in managing liquid and gas flows in various sectors, including oil and gas, water treatment, and chemical manufacturing.

**Tips**: When selecting a globe valve for your system, consider factors such as the medium being controlled, temperature, and pressure ratings. Additionally, ensure you choose a valve that matches your operational needs, especially if flow regulation is a critical requirement for your application. Always consult industry reports to stay updated on material trends and innovations in valve technology.

Key Applications of Globe Valves in Various Industries

Globe valves are essential components in various industrial systems, known for their ability to control flow effectively. In the chemical industry, these valves are widely utilized for regulating the flow of corrosive liquids and gases, ensuring safe and precise operations.

Their design allows for minimal turbulence, making them ideal for maintaining the integrity of sensitive chemical processes. Furthermore, in power generation, globe valves play a crucial role in managing steam and water flow, aiding in the optimization of thermal efficiency and safety measures within boilers and turbines.

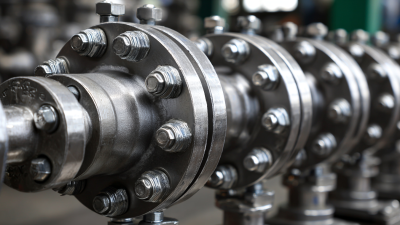

In the water and wastewater treatment sector, globe valves are pivotal in controlling flow rates during filtration and treatment processes. Their reliable sealing properties reduce the risk of leaks, which is vital in maintaining cleanliness and safety in municipal and industrial water systems.

Additionally, in the oil and gas industry, these valves are employed in pipeline systems to regulate the flow of crude oil and natural gas, where precision is necessary to prevent accidents and ensure operational efficiency. The versatility of globe valves in handling various media and pressure conditions underscores their importance across multiple industrial applications.

Comparative Analysis: Globe Valves vs. Other Valve Types

When comparing globe valves to other valve types, it’s essential to understand their unique functionalities and applications in industrial systems. Globe valves are renowned for their excellent throttling capabilities, making them suitable for regulating flow in various applications. Their design allows for minimal pressure drop, unlike gate or ball valves, which are more efficient for on/off control. This characteristic makes globe valves optimal for processes requiring precise flow control, such as in chemical and water treatment industries.

Tips: When selecting a valve for your operations, consider the specific requirements of your system. For applications involving high flow rates, gate valves may be more appropriate. However, if you need to adjust flow frequently, invest in a high-quality globe valve that can handle the changes without compromising performance.

Additionally, it's crucial to evaluate the materials used in valve construction, as these can significantly impact durability and maintenance. While globe valves are resilient, other valve types like ball valves offer lower friction, making them ideal for situations with less frequent adjustments. Understanding these distinctions helps in choosing the right valve type tailored to your specific operational needs.

Maintenance Best Practices for Globe Valves in Industrial Use

Maintenance is crucial for ensuring the longevity and efficiency of globe valves in industrial systems. Regular inspection should be a priority, as it allows for the early detection of wear, corrosion, or leaks. Operators should routinely check the valve stem, packing, and gasket to ensure they are in good condition. Lubricating the valve components periodically helps reduce friction, preventing premature wear and extending the valve’s operational life.

Another important aspect of maintenance is the adherence to proper operating procedures. Globe valves should not be operated at extreme pressure or temperature limits, as this can lead to catastrophic failures. It’s essential to follow the manufacturer’s guidelines for operation and maintenance schedules.

Furthermore, cleaning the valves regularly can prevent build-up of sediment and other deposits that could affect their performance. Implementing a preventive maintenance program that includes these best practices will contribute significantly to the reliability and efficiency of globe valves in any industrial setting.

Future Trends in Globe Valve Design and Technology

The globe valve market is witnessing transformative trends driven by advancements in technology and heightened industrial demands. According to a report by MarketsandMarkets, the global globe valve market is projected to grow from USD 5.11 billion in 2020 to USD 7.12 billion by 2025, at a CAGR of 6.7%. This growth reflects an increasing need for energy efficiency, sustainability, and automated control systems in various sectors, including oil and gas, water treatment, and power generation.

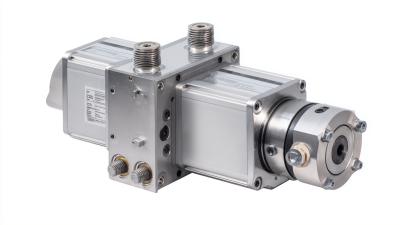

Innovations in materials and design are set to enhance the performance and longevity of globe valves. Enhanced corrosion-resistant materials such as duplex stainless steel and advanced polymers are being adopted, significantly extending the service life and reliability of these components. Furthermore, the integration of smart technologies, including IoT capabilities and predictive maintenance algorithms, is revolutionizing how globe valves are monitored and operated, offering real-time data analytics that optimize flow control and reduce downtime. As industries push towards automation, the future of globe valve design will focus on smarter, more resilient solutions that promise to meet evolving operational challenges.

Related Posts

-

Why Understanding Pneumatic Flow Control Valves is Essential for Efficient Industrial Processes

-

Maximizing Operational Efficiency: The Role of Knife Gate Valves in Modern Industrial Applications

-

Why Pneumatic Rotary Actuators Are Essential for Modern Automation

-

Understanding Electric Actuators: Revolutionizing Automation in Modern Industries

-

How to Choose the Right Basket Strainers for Your Industrial Needs

-

How to Select the Best Butterfly Valve Type for Your Industrial Needs