Blog

2026 Top Hydraulic Actuator Types for Your Applications?

In the evolving landscape of industrial machinery, understanding the various types of hydraulic actuators is crucial. Hydraulic actuators play a vital role in converting hydraulic energy into mechanical motion. An industry expert, Dr. Emily Carter, states, “The right hydraulic actuator can significantly enhance system efficiency.” This highlights the importance of selecting the appropriate actuator for specific applications.

With advancements in technology, the options for hydraulic actuators have expanded. From linear actuators to rotary types, each has unique features. Choosing the wrong actuator can lead to inefficiencies and increased maintenance costs. Thus, it’s essential to evaluate your application requirements carefully.

While the choices seem overwhelming, understanding the pros and cons of each type can simplify the decision-making process. Consider factors like load capacity, speed, and control precision. Taking the time to reflect on these details can prevent future issues. Ultimately, a well-chosen hydraulic actuator can drive performance in various sectors, from manufacturing to aerospace.

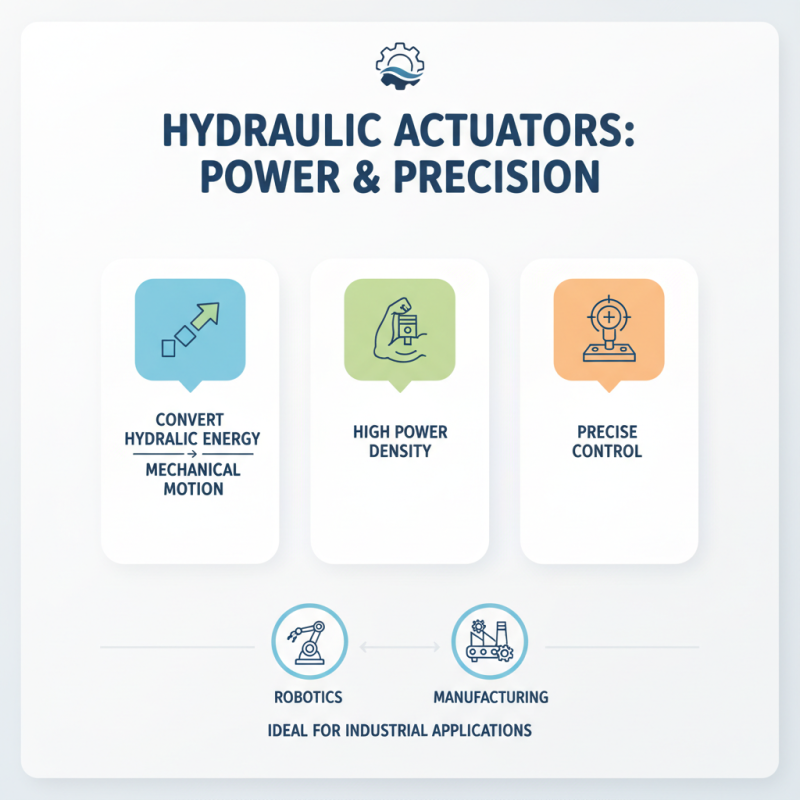

Overview of Hydraulic Actuators and Their Applications

Hydraulic actuators play a crucial role across various industries. These devices convert hydraulic energy into mechanical motion. They offer high power density and precise control, making them ideal for applications like robotics and manufacturing.

According to a recent market report by MarketsandMarkets, the hydraulic actuator market is expected to reach $21.2 billion by 2026, growing at a CAGR of 5.6%. This growth is driven by the expanding construction and automotive sectors. Hydraulic actuators are commonly used in excavators, presses, and even in aerospace applications. Their efficiency often surpasses electric alternatives, yet they can be costly to maintain.

With benefits come challenges. Hydraulic systems can leak, leading to operational inefficiencies and increased costs. Additionally, the complexity of these systems requires skilled personnel for maintenance. Companies often overlook the training needs of their workforce, resulting in underperformance. Choosing the right actuator type for specific applications remains critical, as mismatches can lead to significant downtime and lost revenue.

Key Types of Hydraulic Actuators for Industrial Use

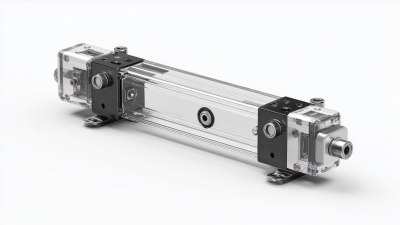

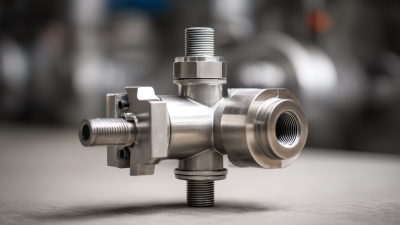

Hydraulic actuators play a critical role in many industrial applications today. These devices utilize pressurized fluid to produce linear or rotary motion. They are essential in machinery like presses, lifts, and conveyor systems. Understanding their types can help optimize performance and efficiency.

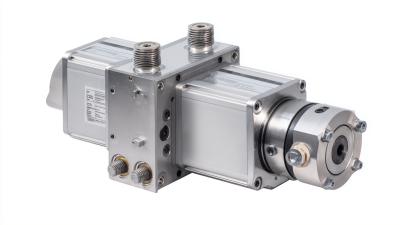

Cylindrical hydraulic actuators are among the most common. They convert hydraulic energy into linear motion. Their design is simple but effective. They come in various sizes, allowing for flexibility in usage. Then there are rotary actuators, which provide torque output. They can rotate objects with precision, making them ideal for applications like robotic arms.

Despite their benefits, hydraulic actuators require regular maintenance. Issues like fluid contamination can lead to performance drops. Additionally, engineers must consider the load limits. Overloading can cause early failures. Attention to detail is vital to prevent costly breakdowns. Operating conditions also matter. High temperatures can affect fluid viscosity. Hence, a thoughtful approach to selection and maintenance is necessary.

2026 Top Hydraulic Actuator Types for Your Applications

Advantages and Disadvantages of Different Hydraulic Actuators

Hydraulic actuators are vital in various applications. They offer immense power but come with specific advantages and disadvantages. One major benefit is their high force output. According to a report by the International Hydraulics Association, hydraulic systems can generate forces exceeding 20,000 Newtons. This makes them suitable for heavy-duty machinery and lifting applications.

However, hydraulic systems also have drawbacks. They can be prone to leaks, which might lead to system failures. A study from the Fluid Power Research Institute indicates that nearly 15% of hydraulic system failures are caused by fluid leaks. Additionally, maintenance can be costly. Hydraulic systems require regular checks, and components can wear down quickly under high stress. Operators must be prepared for unexpected downtime.

Another point to consider is energy efficiency. Hydraulic actuators often consume more power than electric alternatives. This can lead to higher operational costs over time. In some applications, the choice between hydraulic and electric systems may boil down to balancing performance and efficiency. Making an informed decision is crucial for maximizing benefits while minimizing potential issues.

Selection Criteria for Choosing the Right Hydraulic Actuator

Selecting the right hydraulic actuator is crucial for the efficiency of your operations. Start by considering the application conditions. Different environments can affect actuator performance. For instance, temperature fluctuations might influence hydraulic fluid viscosity. Be mindful of the load capacity needed. All actuators have limits, and exceeding them can lead to failures.

Tip: Always check the manufacturer's specifications for load limits. Smaller projects may benefit from compact actuators, while larger systems require powerful units. Think about the speed of actuation. Some applications demand quick responses, requiring faster hydraulic units. Others may not need that urgency and can rely on slower, more precise movements.

Cost is another factor. Balancing quality and budget can be tricky. Investing in a reliable actuator can save costs in the long run. Remember to evaluate the maintenance needs. Some units require regular servicing while others are low-maintenance. Reflect on your operational capacity to handle maintenance before making a decision. Each application will have unique demands, and understanding those can lead you to the ideal actuator for your needs.

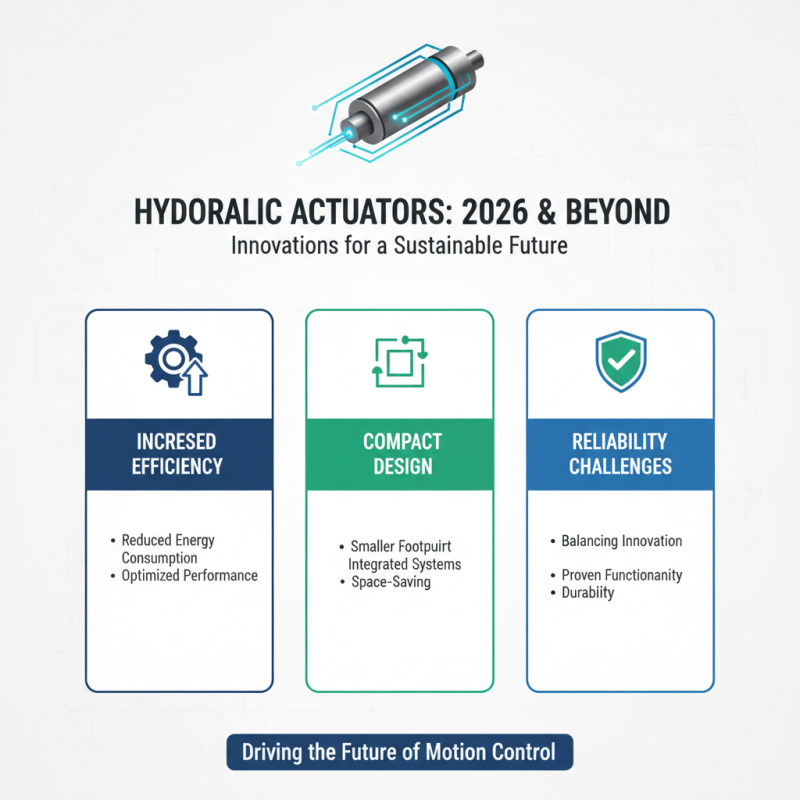

Future Trends in Hydraulic Actuator Technology for 2026

As we approach 2026, hydraulic actuator technology is poised for impressive advancements. The demand for more efficient systems continues to grow. Engineers are striving for compact designs that optimize performance while reducing energy consumption. This shift presents challenges, particularly in maintaining reliability. Manufacturers must balance innovation with proven functionality.

Future trends point to the integration of smart technologies in hydraulic systems. Sensors and IoT connectivity will allow for real-time monitoring and diagnostics, increasing operational efficiency. However, this can mean increased complexity in system maintenance. Operators may find it hard to manage advanced features without proper training.

Additionally, environmental concerns are shaping hydraulic actuator designs. Bio-based fluids and recyclable materials are gaining traction. Yet, the transition could lead to inconsistencies in performance. Innovators must address these issues while maintaining performance standards. The landscape of hydraulic actuators will be vibrant, albeit with hurdles requiring thoughtful solutions.

Related Posts

-

2026 Best Hydraulic Actuator Types for Your Project Needs?

-

Top 10 Hydraulic Actuators: Boost Your Machinery Efficiency Today

-

Understanding Hydraulic Actuators: How They Improve Efficiency in Industrial Automation by 30%

-

Unlocking Automation: The Future of Electric Actuators in Smart Technology

-

Why Pneumatic Rotary Actuators Are Essential for Modern Automation

-

Why Understanding Pneumatic Flow Control Valves is Essential for Efficient Industrial Processes