Blog

Top 5 Pneumatic Valves to Watch in 2025: Features and Applications

As industries increasingly turn towards automation and efficiency, the demand for pneumatic valves is set to rise significantly in 2025. According to a recent report by MarketsandMarkets, the global pneumatic valve market is expected to reach USD 7.36 billion by 2026, growing at a CAGR of 4.7% from 2021. This growth reflects the pivotal role that pneumatic valves play in various applications, including manufacturing, oil and gas, and automotive sectors.

Industry expert Dr. Emily Carter, a renowned authority on fluid control systems, emphasizes the importance of innovation in this field: "The development of advanced pneumatic valves is crucial for optimizing operational efficiency and reducing energy consumption." The focus will be on features such as improved response times, enhanced durability, and integration with smart technologies, which are vital for meeting the evolving demands of modern manufacturing processes.

As we look ahead to 2025, understanding the top pneumatic valves to watch will be essential for engineers and decision-makers alike. This article will explore the latest advancements and applications of pneumatic valves, providing insights into how these integral components can enhance performance and support sustainable practices in various industries.

Overview of Pneumatic Valves and Their Importance in Automation

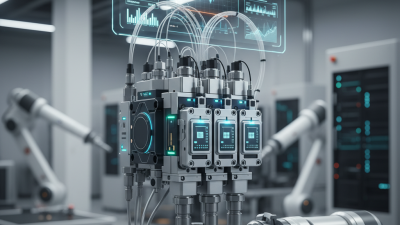

Pneumatic valves play a pivotal role in the

automation landscape, acting as crucial components that control the flow of

compressed air in various systems. By regulating the movement of air, these valves ensure that machinery

operates smoothly and efficiently. Their importance cannot be overstated; they are integral in applications

ranging from manufacturing and packaging to robotics

and process control. The precise management of airflow not only enhances operational efficiency but

also contributes significantly to energy savings and

system reliability.

As industries continue to embrace automation,

the demand for advanced pneumatic valves is likely to increase. Modern pneumatic valves are designed with

features such as faster response times,

greater durability, and

improved energy efficiency, making them more suitable

for a diverse range of applications. Their capabilities allow engineers to optimize processes, minimize

downtime, and ensure safety in complex machinery setups. Understanding the various types of pneumatic valves

and their specific features is essential for professionals aiming to implement effective automation solutions

in their operations.

Key Features to Consider When Selecting Pneumatic Valves

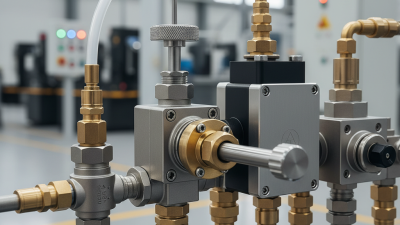

When selecting pneumatic valves, it’s essential to focus on several key features that significantly impact performance and reliability. One of the primary considerations is the valve type, such as solenoid, ball, and needle valves, each offering distinct advantages depending on the application. According to a report by MarketsandMarkets, the global pneumatic valve market is expected to reach approximately $4.5 billion by 2025, reflecting the increasing demand for automation across various industries, including manufacturing and oil and gas.

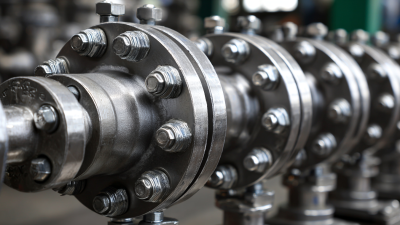

Another critical feature to evaluate is the pressure rating of the valve, as it determines the working conditions for different applications. Pneumatic valves are commonly rated for various pressure levels, with options available for low, medium, and high-pressure systems. Ensuring the correct pressure rating prevents failures that can lead to costly downtime.

Additionally, material compatibility is vital; the choice of materials such as brass, stainless steel, or plastic must align with the fluids being controlled to prevent corrosion and ensure longevity. The right combination of these features allows for efficient operations, as noted in recent industry reports highlighting the importance of integrated valve solutions in improving workflow efficiency by up to 20%.

Top 5 Pneumatic Valves to Monitor for Advancements in 2025

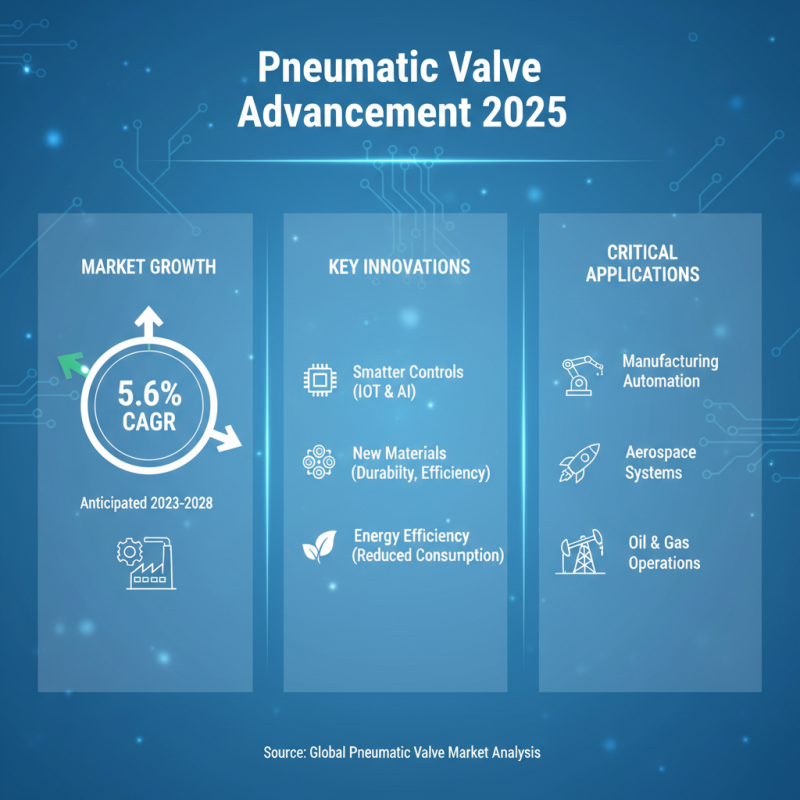

As the pneumatic valve industry evolves, keeping an eye on the advancements expected in 2025 will be crucial for various industrial applications. Recent data from the Global Pneumatic Valve Market Analysis highlights an anticipated CAGR of 5.6% over the next few years, driven by innovations in valve technology and an increasing demand from critical sectors such as manufacturing, aerospace, and oil and gas. This growth emphasizes the importance of understanding the features and applications of the leading pneumatic valves.

One key area of advancement is in smart pneumatic valves, which integrate IoT technology and advanced automation features. These valves are designed not only to optimize performance but also to provide real-time data analytics, leading to more efficient operations and maintenance. A report from the International Society of Automation suggests that implementing smart valves can reduce operational costs by 20% while enhancing system reliability. Moreover, environmentally friendly options, such as those designed to minimize air leakage and reduce energy consumption, are becoming increasingly relevant as industries strive to meet sustainability goals.

Additionally, developments in materials science are enabling the production of valves that offer greater resistance to corrosion and wear. This is crucial in applications where harsh environments can significantly affect operational longevity. As industries continue to prioritize efficiency and sustainability, monitoring these advancements in pneumatic valves will be key to optimizing their processes for the future.

Application Areas for Pneumatic Valves in Industrial Settings

Pneumatic valves play a crucial role in various industrial applications, providing efficient control of air flow and pressure in systems. One significant application area for these valves is in manufacturing processes, where they are utilized to automate machinery and streamline production lines. By controlling actuators, such as cylinders and motors, pneumatic valves help increase productivity and enhance safety by minimizing human intervention in potentially dangerous tasks.

Another vital area for pneumatic valves is in the food and beverage industry, where hygiene and precision are paramount. These valves enable the accurate control of air and gas flow in processes such as packaging, filling, and mixing. Their ability to withstand harsh cleaning agents and their reliable performance in sterile environments make them ideal for ensuring compliance with safety standards while maintaining the quality of the products.

Furthermore, pneumatic valves are extensively used in the automotive sector, specifically in assembly lines for controlling robotic arms and conveyors. Their rapid response times and robust design ensure efficient operations, significantly reducing downtime and increasing throughput. As industries evolve, the demand for advanced pneumatic valves tailored to specific applications will continue to grow, indicating a promising path for innovation and development in this field.

Top 5 Pneumatic Valves to Watch in 2025: Features and Applications

Future Trends and Innovations in Pneumatic Valve Technology

In 2025, pneumatic valve technology is poised for significant evolution, driven by new innovations that enhance efficiency and responsiveness in various applications. One of the most notable trends is the integration of smart technology within pneumatic valves. By embedding sensors and IoT capabilities, these valves can provide real-time data on system performance, leading to improved maintenance strategies and reduced downtime. This shift towards smarter systems not only boosts operational efficiency but also allows for predictive analytics in industrial environments, optimizing both productivity and safety.

Another key innovation is the development of materials that increase the durability and reliability of pneumatic valves. Advances in lightweight, corrosion-resistant materials will expand the range of environments in which these valves can operate effectively. This is particularly important in industries where exposure to harsh conditions is common, such as in chemical processing and oil and gas. Enhanced materials mean that manufacturers can design valves that withstand extreme temperatures and pressures, thereby extending their lifespan and reducing the need for frequent replacements.

Tips: When selecting pneumatic valves, consider the compatibility of materials with the specific media they will control. Additionally, look for options that allow for easy integration with existing systems, especially if you are investing in smart technology. Staying ahead of these trends will ensure that you are equipped with the most innovative solutions available on the market.

Top 5 Pneumatic Valves to Watch in 2025: Features and Applications

| Valve Type | Key Features | Applications | Future Trends |

|---|---|---|---|

| Solenoid Valve | Fast response time, compact design | Automation, Robotics | Increased integration with IoT |

| Butterfly Valve | Lightweight, low pressure drop | Water treatment, HVAC systems | Focus on energy efficiency |

| Ball Valve | Durability, good sealing capability | Oil & Gas, Chemical Processing | Advances in materials for harsh environments |

| Check Valve | Prevention of backflow, simple design | Pneumatic systems, Water supply | Enhanced monitoring features |

| Pressure Relief Valve | Automatic operation, safety features | Compressed air systems, Hydraulics | Smart pressure regulation technology |

Related Posts

-

Why Understanding Pneumatic Flow Control Valves is Essential for Efficient Industrial Processes

-

Why Pneumatic Rotary Actuators Are Essential for Modern Automation

-

2025 Top 5 Pneumatic Control Valves for Optimal Industrial Automation

-

Exploring the Future of Pneumatic Control Valves in 2025 Top Digital Innovations

-

Top Pneumatic Flow Control Valve Types Explained: Choosing the Right One

-

How to Select the Best Butterfly Valve Type for Your Industrial Needs