Blog

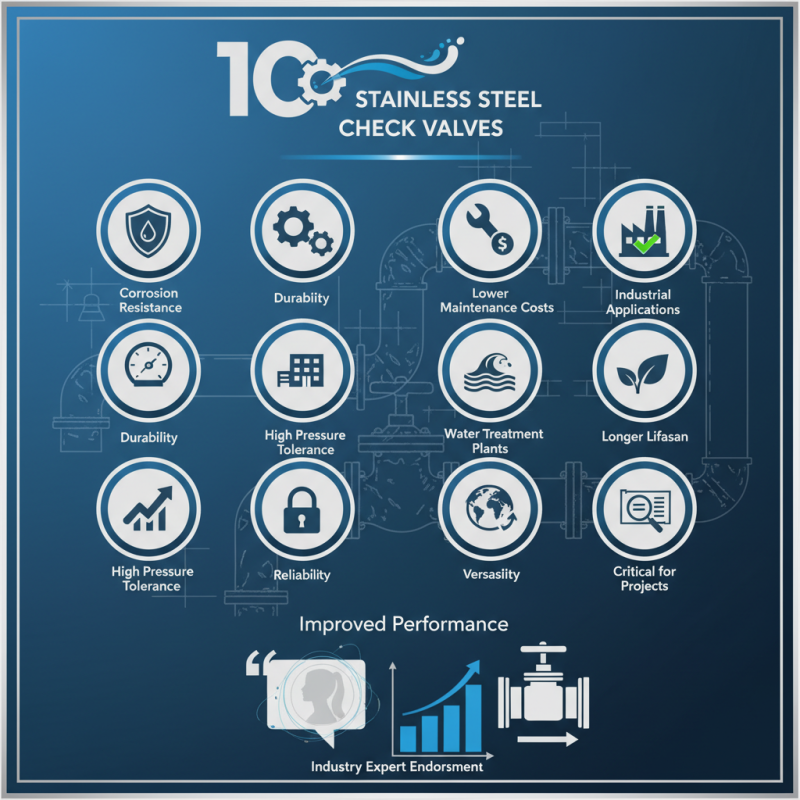

Top 10 Reasons to Choose Stainless Steel Check Valves for Your Projects?

When considering the best valves for your projects, stainless steel check valves stand out. Renowned industry expert Dr. Anna Li, a leading engineer at ValveTech Industries, emphasizes, “Choosing the right material is crucial for ensuring longevity and reliability.” Her words underscore the importance of selecting stainless steel in various applications.

Stainless steel check valves offer durability. They resist corrosion, even in harsh environments. For example, in water treatment plants, these valves maintain their integrity over time. This reliability leads to fewer replacements and lower maintenance costs.

Yet, not all stainless steel check valves are created equal. Some may not perform well under extreme pressure. It’s essential to choose a reputable manufacturer. The right selection requires careful consideration. Ultimately, understanding the unique benefits and potential drawbacks of stainless steel check valves can lead to better decisions in project planning.

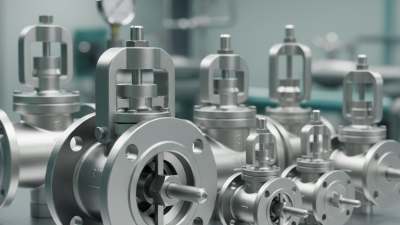

The Durability of Stainless Steel in Check Valve Applications

Stainless steel check valves excel in durability, making them an ideal choice for various applications. According to a report by the European Valve Manufacturer Association, stainless steel valves typically have a lifespan of over 20 years when properly maintained. This longevity can significantly reduce replacement costs and downtime in industrial settings.

These valves resist corrosion from harsh chemicals and extreme temperatures. For instance, tests show that stainless steel maintains structural integrity in environments ranging from -200°C to 600°C. This versatility adds to their appeal in sectors like oil and gas, where conditions can be unforgiving. However, it’s worth noting that even stainless steel can suffer from pitting corrosion if not specified correctly.

Maintenance requirements can be minimal, but they still exist. Regular inspections are essential to address potential issues early. In some cases, valve failure may go unnoticed, leading to unexpected downtimes. Understanding this inherent risk is crucial for project managers who prioritize reliability. The combination of resilience and oversight creates a robust framework for using stainless steel check valves effectively.

Corrosion Resistance: A Key Advantage for Long-Term Use

When selecting materials for projects, corrosion resistance stands out. Stainless steel check valves excel in this area. They resist rust and degradation, even in harsh environments. This quality is vital for long-term use. Imagine a pipeline in a chemical plant. If the valve fails, the consequences can be dire. Stainless steel minimizes this risk significantly.

Another consideration is maintenance. With other materials, the upkeep can be extensive. Yet, stainless steel requires less frequent checks. This efficiency can save time and costs. However, one might still encounter issues like pitting or crevice corrosion. It's essential to regularly inspect and address these concerns. The focus on corrosion resistance can lead to a more reliable system overall, but vigilance remains crucial. Balancing these factors can make all the difference in project success.

Top 10 Reasons to Choose Stainless Steel Check Valves for Your Projects

| Reason | Description | Advantage |

|---|---|---|

| Corrosion Resistance | Stainless steel offers excellent resistance to rust and corrosion in various environments. | Longer lifespan and reduced maintenance costs. |

| Durability | Can withstand high pressure and temperature variations without failing. | Reliable operation in demanding conditions. |

| Low Maintenance | Requires minimal maintenance compared to other materials. | Saves time and resources for project managers. |

| Versatility | Suitable for a wide range of applications, from water systems to chemical processing. | Effective across various industries. |

| Hygiene | Non-porous surface prevents bacteria and pathogens from settling. | Ideal for food and pharmaceutical industries. |

| Aesthetic Appeal | Modern and sleek appearance enhances project design. | Improves the overall look of installations. |

| Recyclability | Made from recyclable materials, reducing waste. | Environmentally friendly choice. |

| Cost-Effectiveness | While initial costs can be higher, the long-term savings are significant. | Better investment over time. |

| Pressure Handling | Designed to handle high flow rates and pressure without failing. | Ensures safety and functionality in critical applications. |

| Customizability | Available in various sizes and configurations to meet specific project requirements. | Flexibility to adapt to project specifications. |

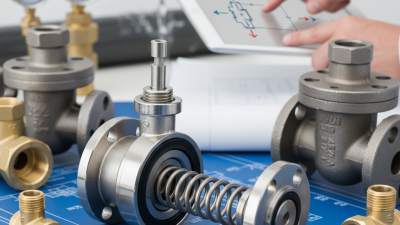

Flow Efficiency and Pressure Maintenance in Fluid Systems

When it comes to fluid systems, flow efficiency is crucial. Stainless steel check valves play an important role in maintaining optimal flow rates. These valves ensure that fluids move in one direction only. This prevents backflow, which can cause pressure drops and system inefficiencies.

Pressure maintenance is another key aspect of fluid systems. Stainless steel check valves can withstand high pressures without deforming. Their durability helps to maintain consistent pressure levels throughout the system. Over time, some valves may wear out or develop leaks. Regular maintenance is necessary to ensure reliable performance.

Choosing the right valve can be challenging. There are many factors to consider, including material, size, and pressure ratings. However, stainless steel check valves offer a blend of strength and functionality. Their resistance to corrosion is also beneficial in harsh environments. In industries like water treatment and chemical processing, these valves can be a dependable choice.

Cost-Effectiveness Over Time: A Comparison with Other Materials

Stainless steel check valves are often praised for their durability and versatility. When it comes to cost-effectiveness, they shine compared to other materials. A study by the American Society of Mechanical Engineers (ASME) shows stainless steel valves can last 15 years longer than plastic ones. This longevity reduces replacement costs significantly, making them a true investment.

Maintenance is another crucial factor. Stainless steel is resistant to corrosion and scaling, which translates to lower upkeep expenses. Reports indicate that maintenance costs for stainless steel valves can be 30% lower than those for carbon steel valves in harsh environments. It's essential to evaluate these long-term expenses when choosing materials for projects.

**Tip:** Always consider the specific environment of your project. The initial cost of stainless steel might seem higher. Yet, the long-term savings in maintenance and replacements often outweigh this.

**Tip:** Look into the lifecycle costs of different valves. It may reveal that investing in stainless steel is more beneficial over time. Remember, cheaper options today can lead to higher costs tomorrow.

Cost-Effectiveness of Stainless Steel Check Valves Compared to Other Materials

This chart illustrates the maintenance costs of stainless steel check valves compared to other materials over a period of 10 years. As shown, stainless steel offers significant cost-effectiveness in the long term.

Industry Standards and Certifications Supporting Stainless Steel Valves

When selecting check valves for projects, it's vital to prioritize industry standards and certifications. Stainless steel check valves frequently meet rigorous certifications like ISO and ASTM. These standards ensure reliability and quality. They undergo strict testing for pressure and temperature stability.

Tips: Always check for industry certifications before purchasing. You want to make sure your valves can handle the conditions they'll face.

Using stainless steel valves adds corrosion resistance. This material holds up well in harsh environments, such as chemical processing. But it's important to evaluate potential weaknesses, like improper installation.

Tips: Consider using multiple suppliers. This helps reduce the risk of receiving non-compliant products. Sometimes, a better price doesn't mean better quality. Evaluate different options thoroughly.

Related Posts

-

How to Choose the Right Stainless Steel Check Valve for Your Plumbing Needs

-

Understanding the Role of Spring Check Valves in Modern Fluid Systems: A Comprehensive Guide

-

Understanding the Importance of Spring Check Valve in Modern Plumbing Systems

-

2026 How to Choose the Right Stainless Steel Check Valve for Your Needs?

-

How to Choose the Right Spring Check Valve for Your Application?

-

Top Motorized Valves for 2025 Which One is Right for Your Needs