Blog

Top 5 Types of Butterfly Valves You Need to Know for Optimal Performance

In the realm of fluid control, butterfly valves play a crucial role due to their efficiency and versatility. As we navigate through the numerous options available, understanding the various butterfly valve types is essential for optimal performance in industrial applications. Renowned industry expert, Dr. Emily Carter, highlights the importance of this knowledge, stating, "Choosing the right butterfly valve type can significantly affect the operational efficiency and longevity of your system."

With advancements in technology, different butterfly valve types have emerged to meet the diverse needs of various sectors, from water treatment to manufacturing. This article delves into the top five butterfly valve types you need to know, providing insights into their unique features and applications. By familiarizing yourself with these distinct options, you can make informed decisions that will enhance the performance of your fluid management systems and ultimately lead to better operational outcomes.

Understanding the Basics of Butterfly Valves for Optimal Use

Butterfly valves are essential components in various industrial processes, designed for regulating flow efficiently. Understanding the fundamentals of butterfly valves is crucial for optimizing their performance across different applications. These valves operate by rotating a disc to control fluid passing through a pipeline, making them ideal for quick shut-off and flow regulation. Their simplicity in design allows for easy maintenance and suitability in space-constrained installations, making them a preferred choice in modern engineering.

When selecting the right type of butterfly valve, consider factors such as size, pressure rating, and the fluids being handled. Each type of butterfly valve serves specific needs—wafer, lug, and double-flanged varieties cater to distinct installation requirements while achieving optimal performance in fluid management. Knowing the characteristics and applications of these valves can significantly enhance operational efficiency and reliability in various setups, from water distribution systems to sophisticated industrial processes. By focusing on the basics of butterfly valves, users can make informed decisions to ensure their systems run smoothly and effectively.

Key Features and Benefits of Different Butterfly Valve Types

When considering butterfly valves for optimal performance in various applications, understanding the key features and benefits of different types is essential. Butterfly valves are widely favored for their compact design and ability to control flow in pipelines efficiently. The most common types include resilient-seated, high-performance, and triple-offset butterfly valves, each serving unique operational needs. For instance, resilient-seated butterfly valves are perfect for applications requiring tight sealing with low pressure, while high-performance valves handle greater pressure and temperature variations, making them suitable for critical process systems.

Recent industry reports indicate that the global butterfly valve market is expected to grow significantly, driven by increasing demand in water supply, wastewater treatment, and industrial sectors. The lightweight design of butterfly valves not only offers ease of installation but also minimizes maintenance costs, which can enhance overall system efficiency. Moreover, innovations in valve materials and manufacturing techniques are paving the way for more durable and environmentally friendly options. As industries seek sustainable solutions, the adoption of advanced butterfly valve technologies will play a crucial role in enhancing operational capabilities while minimizing environmental impact.

Top 5 Types of Butterfly Valves You Need to Know for Optimal Performance

| Type of Butterfly Valve | Key Features | Benefits | Applications |

|---|---|---|---|

| Traditional Butterfly Valve | Simplicity in design, reliable control | Cost-effective, easy to maintain | Water supply systems, HVAC |

| Wafer Butterfly Valve | Compact and lightweight, no flanges | Reduces installation space, less weight | Piping systems, chemical processing |

| Lugged Butterfly Valve | Bolt holes for easy installation/removal | Allows for maintenance without disrupting the line | Fire protection, oil and gas |

| Electrically Actuated Butterfly Valve | Remote operation, automation-friendly | Increases efficiency in system management | Water treatment, wastewater management |

| Double Offset Butterfly Valve | Enhanced sealing with a double offset design | High durability, reduces wear | High-pressure applications, oil field services |

Comparison of Materials Used in Butterfly Valve Manufacturing

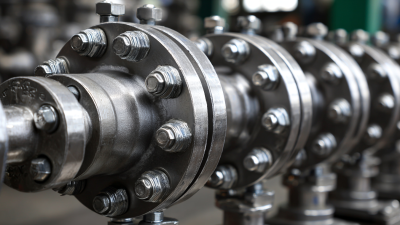

When it comes to butterfly valves, the choice of material significantly influences performance, durability, and cost-effectiveness. The most common materials used in butterfly valve manufacturing include cast iron, stainless steel, and plastic.

Cast iron is widely preferred for its strength and ability to handle high-pressure applications. However, it is also relatively heavy and may not perform well in corrosive environments.

On the other hand, stainless steel butterfly valves are known for their excellent corrosion resistance and longevity. They are ideal for harsh conditions, including chemical processing and food industries, where cleanliness and resistance to media are crucial.

Plastic butterfly valves, typically made from PVC or CPVC, are lightweight and resistant to chemical degradation, making them suitable for various industrial applications, including wastewater treatment and irrigation. Choosing the right material based on operational conditions is essential for ensuring optimal performance and extending the lifespan of the valve.

Application Scenarios: Choosing the Right Butterfly Valve for Your Needs

When selecting a butterfly valve for specific applications, understanding the unique requirements of your system is essential. Different types of butterfly valves excel in particular scenarios, ensuring optimal performance and longevity. For instance, in high-pressure applications, a resilient seated butterfly valve is often preferred due to its ability to maintain a tight seal while accommodating fluctuations in pressure. This makes it ideal for water treatment facilities and various industrial processes.

In contrast, fire-safe butterfly valves are specially designed for scenarios where safety is paramount. These valves are built to withstand extreme temperatures and prevent leaks in the event of a fire, making them suitable for petroleum and chemical industries. Additionally, when dealing with corrosive substances, a butterfly valve made from high-quality materials such as PVC or stainless steel would be essential to prevent degradation and maintain system integrity. By carefully matching the type of butterfly valve to the specific application, operators can ensure efficiency, safety, and reduced maintenance costs.

Top 5 Types of Butterfly Valves You Need to Know for Optimal Performance

This chart illustrates the number of applications for each type of butterfly valve. Wafer Butterfly Valves are the most commonly used, followed by Lug and Electric Butterfly Valves. This information can help you choose the right valve for your specific needs.

Maintenance Tips for Ensuring Long-Term Performance of Butterfly Valves

Maintaining butterfly valves is crucial for achieving optimal performance and extending their service life. According to a report by the Valve Manufacturers Association, improper maintenance can reduce valve life by up to 50%. Regular inspections should be conducted to check for leaks, wear, and corrosion. It’s advisable to perform a thorough visual inspection every six months, especially in environments with harsh conditions or where the valves operate under high pressures.

Additionally, lubrication of the valve shafts and seals is essential for smooth operation. The American Society of Mechanical Engineers recommends using a high-quality lubricant and following the manufacturer's guidelines to prevent sticking and minimize torque requirements. Furthermore, operators should consider the application-specific conditions when selecting materials for butterfly valves, as the right choice can significantly impact maintenance needs. A recent study highlighted that using corrosion-resistant materials can decrease maintenance frequency by 30%, underscoring the importance of selecting appropriate valve types based on the operational environment.

Related Posts

-

How to Select the Best Butterfly Valve Type for Your Industrial Needs

-

Top 5 Benefits of Using Pneumatic Butterfly Valves in Industrial Applications

-

Maximizing Operational Efficiency: The Role of Knife Gate Valves in Modern Industrial Applications

-

Exploring Duplex Strainer Innovations at the 138th Canton Fair in 2025

-

Understanding the Importance of Spring Check Valve in Modern Plumbing Systems

-

Understanding Electric Actuators: Revolutionizing Automation in Modern Industries