Blog

Understanding Electric Actuators: Revolutionizing Automation in Modern Industries

The rise of electric actuators has transformed automation across various industries, leading to enhanced efficiency and precision in operations. According to a report by MarketsandMarkets, the global electric actuator market is expected to reach $48 billion by 2026, reflecting a compound annual growth rate (CAGR) of 6.4% from 2021. This significant growth can largely be attributed to the increasing demand for energy-efficient solutions and automation in manufacturing processes. Electric actuators offer notable advantages over traditional pneumatic and hydraulic systems, including reduced energy consumption, lower maintenance costs, and improved control and responsiveness.

As industries seek to optimize their operations amidst competitive pressures, understanding the various types of electric actuators and their applications becomes crucial for leveraging their capabilities to achieve operational excellence.

The Fundamentals of Electric Actuators: Types and Mechanisms

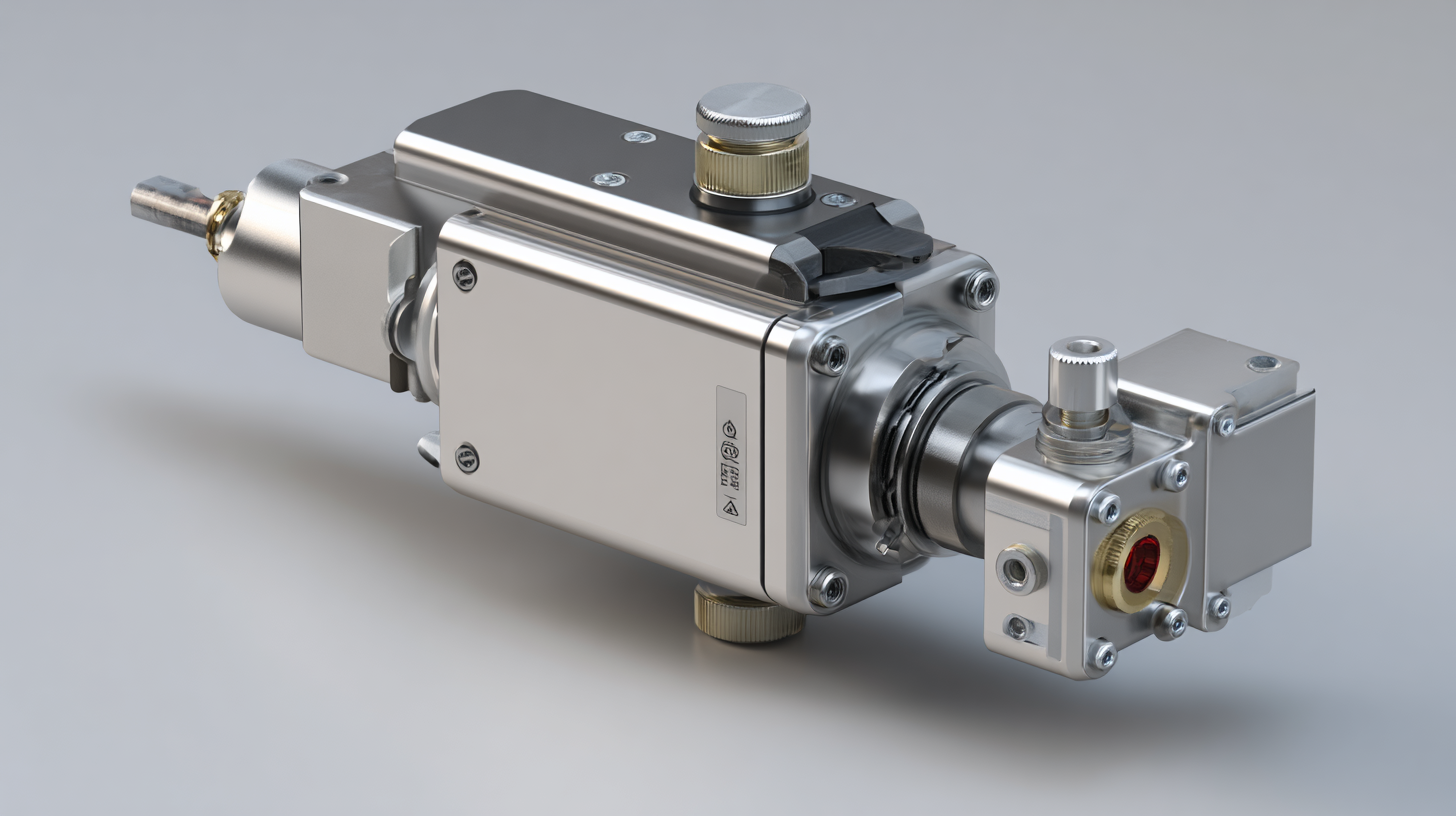

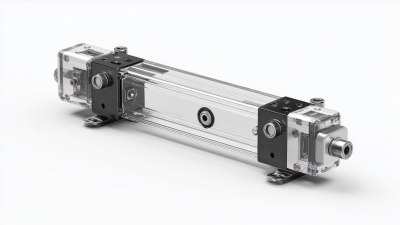

Electric actuators are integral components in modern automation, driving advancements across various industries. They convert electrical energy into mechanical motion, enabling precise control over machinery and processes. The fundamental types of electric actuators include linear and rotary actuators, each serving distinct applications based on their mechanism of action. Linear actuators create motion in a straight line, while rotary actuators facilitate circular motion, making them vital in robotics and manufacturing operations.

Recent advancements in actuator technology, particularly untethered soft actuators, demonstrate a shift towards more flexible and adaptable systems. These soft actuators enable the creation of lightweight and versatile robotic solutions capable of operating in diverse environments. Additionally, innovations in micropump technology highlight evolving mechanisms and applications, particularly in the biomedical field, showcasing the adaptability of electric actuators in addressing industry-specific challenges. Coupled with essential motion control principles, the evolution of actuator mechanisms plays a crucial role in enhancing automation efficiency and capability across modern industries.

Understanding Electric Actuators: Types and Mechanisms

Applications of Electric Actuators in Various Industries

Electric actuators are becoming an integral part of various industries, enhancing efficiency and precision in automation processes. In manufacturing, electric actuators are widely used in robotic systems, enabling precise movements for tasks such as assembly, welding, and painting. These actuators replace traditional pneumatic systems, offering better control and energy savings. In the agricultural sector, they're used in automated irrigation systems, ensuring optimal water distribution while minimizing waste.

Tip: When selecting electric actuators, consider factors such as load capacity, speed, and environmental conditions. This ensures the actuator meets the specific demands of your application.

In the healthcare industry, electric actuators play a vital role in medical devices. From hospital beds that adjust to provide patient comfort to surgical robots that enhance precision during operations, their ability to provide controlled movements is crucial. Additionally, in the transportation sector, electric actuators are utilized in electric vehicles for controlling systems like brakes and steering, contributing to improved safety and responsiveness.

Tip: Regular maintenance of electric actuators can extend their lifespan and maintain high performance. Implementing a routine inspection schedule helps in identifying issues early on.

Key Benefits of Integrating Electric Actuators in Automation

Electric actuators have become pivotal in automating modern industries, offering several key benefits that enhance operational efficiency. According to a report by Research and Markets, the global market for electric actuators is expected to reach $25 billion by 2026, driven by the need for precise control and reliability in various applications. One significant advantage of electric actuators is their ability to provide high accuracy and repeatability in movement, which is crucial in manufacturing processes. This precision reduces waste and improves product quality, allowing industries to meet stringent standards and customer demands.

Electric actuators have become pivotal in automating modern industries, offering several key benefits that enhance operational efficiency. According to a report by Research and Markets, the global market for electric actuators is expected to reach $25 billion by 2026, driven by the need for precise control and reliability in various applications. One significant advantage of electric actuators is their ability to provide high accuracy and repeatability in movement, which is crucial in manufacturing processes. This precision reduces waste and improves product quality, allowing industries to meet stringent standards and customer demands.

Moreover, electric actuators are more energy-efficient compared to their pneumatic and hydraulic counterparts. A study by Grand View Research highlights that electric actuators can achieve energy savings of up to 30% due to their on-demand power usage and lower maintenance requirements. This not only reduces operational costs but also contributes to a company's sustainability goals by minimizing energy consumption. As industries continuously seek to optimize their processes, the integration of electric actuators positions them to enhance productivity while maintaining environmental responsibility.

Challenges and Considerations When Choosing Electric Actuators

When selecting electric actuators for industrial applications, several challenges and considerations come into play. The market for electric actuators is projected to grow significantly, with a report from Research and Markets estimating a compound annual growth rate (CAGR) of 6.3% from 2021 to 2026. This growth highlights the increasing reliance on electric actuators in various sectors, such as manufacturing, energy, and transportation. However, choosing the right actuator is crucial for optimizing performance and ensuring long-term reliability.

One primary consideration is the actuator's load capacity and speed requirements. For instance, in automation systems, actuators must not only support the weight of the load but also achieve required motion speeds without compromising safety or precision. Additionally, environmental factors such as temperature, humidity, and the presence of dust or chemicals can affect the actuator's performance. A study by MarketsandMarkets indicates that these environmental considerations will drive innovation in actuator designs, leading to more robust solutions tailored to specific industrial needs.

**Tips:**

- Always assess the specific application requirements, including torque, stroke length, and response time, before selecting an actuator.

- Consult with manufacturers to understand the best materials and protection ratings for your operating environment, ensuring the actuator can withstand external conditions.

Future Trends: Innovations Shaping Electric Actuator Technology

The landscape of electric actuators is rapidly evolving, driven by innovations that are set to redefine automation across industries. According to a recent report by MarketsandMarkets, the electric actuator market is projected to grow from USD 29.2 billion in 2021 to USD 41.3 billion by 2026, at a compound annual growth rate (CAGR) of 7.6%. This growth is largely attributed to advancements in technologies such as IoT, AI, and machine learning, which are enabling more precise control and improved efficiency in various applications.

Future trends indicate a significant shift towards smart actuators equipped with sensors and connectivity features. A study by Grand View Research highlights that the integration of smart technologies is expected to enhance operational capabilities, allowing for real-time monitoring and predictive maintenance. The increased demand for automation in sectors like manufacturing, healthcare, and energy management is driving the development of innovative electric actuators that can interact seamlessly with existing digital ecosystems, thereby optimizing processes and reducing downtime. As industries seek to maximize productivity while minimizing energy consumption, electric actuators are poised to play a pivotal role in shaping the future of automation technology.

Related Posts

-

Unlocking Automation: The Future of Electric Actuators in Smart Technology

-

Exploring Pneumatic Rotary Actuator Innovations at 2025 China Import and Export Fair

-

Understanding the Benefits of Butterfly Valves in Modern Industrial Applications

-

How to Choose the Right Pneumatic Valve for Your Industrial Application

-

How to Select the Best Butterfly Valve Type for Your Industrial Needs

-

Exploring Air Actuator Innovations at the 138th Canton Fair 2025 in China