Blog

Why Understanding Pneumatic Flow Control Valves is Essential for Efficient Industrial Processes

In today's rapidly evolving industrial landscape, the optimization of processes is more critical than ever. According to a report by the International Society of Automation, pneumatic systems account for approximately 70% of all industrial actuators, underscoring the importance of pneumatic technologies in enhancing operational efficiency. Central to these systems is the pneumatic flow control valve, which plays a pivotal role in regulating the flow of air, thereby ensuring precise control over motion and output. A study conducted by Research and Markets predicts that the global market for pneumatic valves is expected to reach $3.5 billion by 2025, driven by increasing automation and the need for energy-efficient processes. Understanding the functionality and applications of pneumatic flow control valves is essential for engineers and operators alike, as they can significantly impact productivity, reduce energy consumption, and improve equipment longevity in various industrial applications.

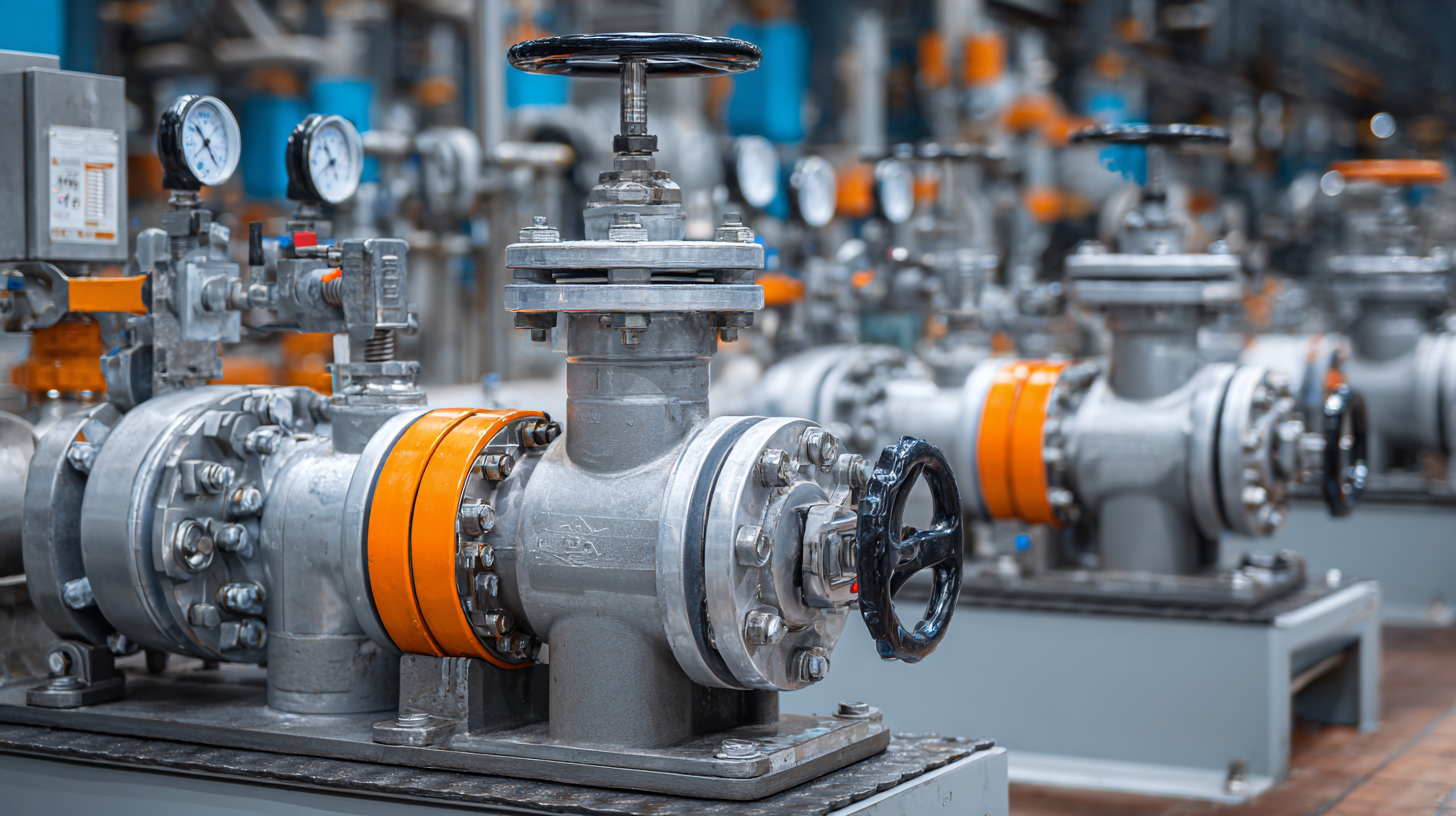

Importance of Pneumatic Flow Control Valves in Industrial Applications

Pneumatic flow control valves play a crucial role in enhancing the efficiency of industrial processes. As industries increasingly demand precision and control, understanding the functionality of these valves becomes essential. They regulate the flow of compressed air, ensuring that machines operate smoothly and effectively. With the rise of automation in various sectors, the need for intelligent pneumatic systems has surged. Businesses are now seeking solutions that not only improve operational efficiency but also contribute to sustainability goals.

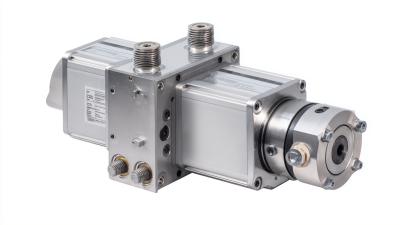

Recent advancements in technologies, such as piezoelectric controls, further enhance the capabilities of pneumatic systems, offering improved precision and responsiveness. The control valve market is projected to experience substantial growth, driven by the need for smart fluid power systems. As industries evolve, the importance of pneumatic flow control valves will only increase, making it imperative for professionals to stay informed about the latest technological developments and industry standards. This understanding will facilitate the implementation of efficient processes, ultimately leading to increased productivity and reduced operational costs.

Key Components and Functionality of Pneumatic Flow Control Valves

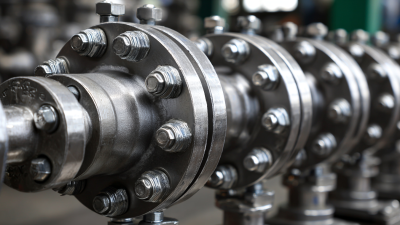

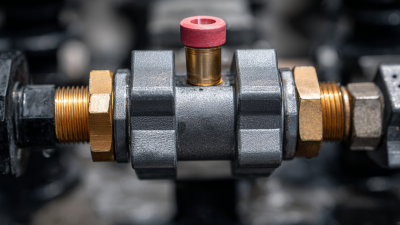

Pneumatic flow control valves play a pivotal role in managing the movement of air within industrial systems, directly affecting efficiency and performance. These valves regulate the flow rate and pressure of compressed air, which is crucial for various applications in manufacturing and assembly lines. Understanding their key components — such as the orifice, actuator, and control mechanism — helps operators select the right valve for their specific needs, ensuring optimal airflow management and minimizing energy waste.

To effectively utilize pneumatic flow control valves, one should consider a few essential tips. First, regularly inspect and maintain the valves to ensure they function correctly and efficiently. Accumulation of dirt or debris can impair the valve’s performance, leading to increased energy consumption. Second, it’s important to understand the relationship between flow rate and pressure. Adjusting one can significantly impact the other, so it’s beneficial to monitor both when making adjustments for system optimization. Finally, exploring newer technologies in valve design may offer enhancements in functionality and efficiency, contributing to better industrial process performance.

Impact of Flow Control on Process Efficiency and Productivity

Pneumatic flow control valves play a crucial role in optimizing industrial processes by regulating the flow of compressed air. Understanding how these valves operate can significantly impact process efficiency and productivity. When flow is precisely controlled, operations can maintain consistent pressure and speed, leading to a smoother workflow and minimized downtime. This is especially vital in environments where timing and precision are paramount, such as assembly lines or manufacturing plants.

Tips: Regular maintenance of flow control valves is essential. Checking for wear and ensuring seals are intact can prevent leaks that waste energy and reduce efficiency. Additionally, calibrate the valves regularly to align with system requirements; this ensures that processes run at their optimal capacity.

Moreover, the choice of the right type of flow control valve, whether proportional, needle, or standard, can influence not only the efficiency but also the effectiveness of the process. An appropriate selection tailored to specific applications ensures that the system responds adequately to changes in demand, thereby enhancing overall productivity while minimizing resource consumption.

Common Issues and Solutions in Pneumatic Flow Control Systems

Pneumatic flow control systems play a crucial role in various industrial applications, ensuring the precise management of air flow to optimize machine performance. However, these systems can encounter several common issues that may hinder operational efficiency. One frequent problem is air leakage, which can arise from worn seals or improperly connected components. This not only leads to wasted energy but may also affect the overall system pressure, resulting in inconsistent performance.

Pneumatic flow control systems play a crucial role in various industrial applications, ensuring the precise management of air flow to optimize machine performance. However, these systems can encounter several common issues that may hinder operational efficiency. One frequent problem is air leakage, which can arise from worn seals or improperly connected components. This not only leads to wasted energy but may also affect the overall system pressure, resulting in inconsistent performance.

Another common issue is the improper sizing of valves, which can restrict or over-allow airflow, thereby causing erratic operation or failure in achieving desired speed adjustments. Implementing regular maintenance checks and ensuring that components are correctly rated for the specific application can help mitigate these problems. Additionally, utilizing adjustable flow control valves can offer greater flexibility in managing pneumatic systems, allowing operators to fine-tune air flow according to real-time demands. By addressing these common issues with effective solutions, industries can ensure smoother operations and enhance productivity in their processes.

Best Practices for Selecting and Maintaining Flow Control Valves

When selecting flow control valves for pneumatic systems, understanding the critical parameters and specifications is key. Reports indicate that improper selection can lead to efficiency losses of up to 25% in industrial processes. Therefore, it's essential to consider factors such as flow rate, temperature, pressure, and the type of media being controlled. For instance, the International Society of Automation suggests that matching the valve type—such as needle, globe, or proportional valves—with the specific application can optimize performance and reduce wear.

Maintenance practices are equally vital for sustaining the performance of pneumatic flow control valves. According to industry data, regular inspection and cleaning of valve components can extend their lifespan by nearly 40%. Implementing a preventative maintenance schedule that includes checking for leaks, calibrating controls, and replacing worn parts will minimize downtime and operational disruptions. Utilizing remote monitoring technologies can also facilitate real-time tracking of valve performance, further enhancing reliability in demanding industrial environments. Adopting these best practices not only improves efficiency but also fortifies the reliability of the overall pneumatic system.